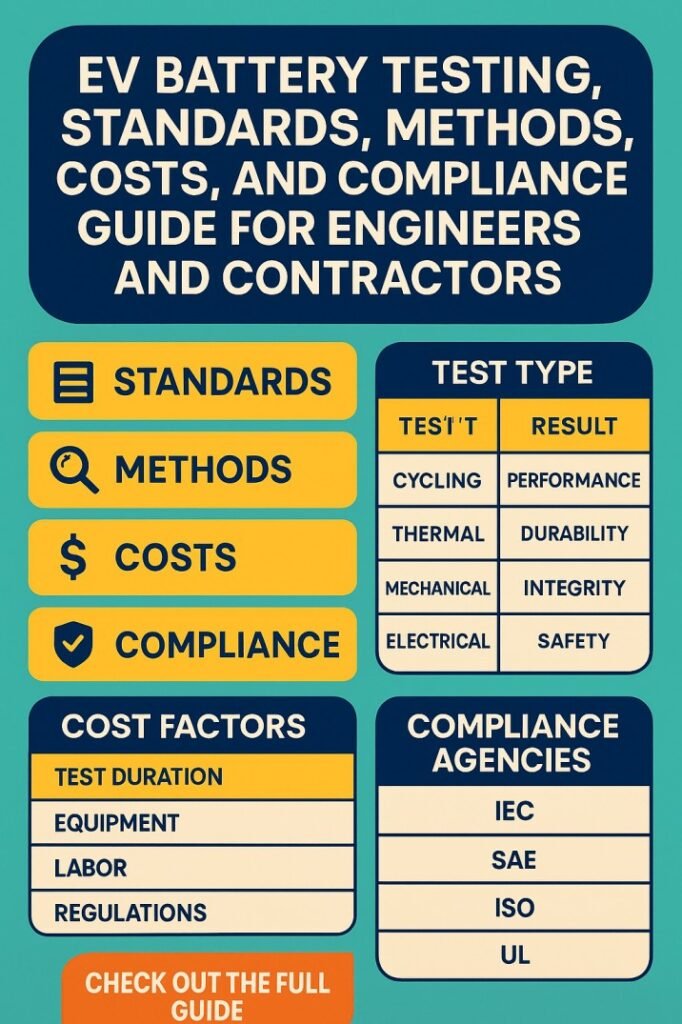

EV Battery Testing Standards, Methods, Costs, and Compliance Guide for Engineers and Contractors

EV battery testing is a critical part of modern electric vehicle projects, whether you are working in manufacturing, installation, maintenance, or compliance inspection. Engineers and contractors rely on proper EV battery testing to ensure safety, performance, regulatory approval, and long service life. With high energy density systems now common in transport, commercial fleets, and energy storage integration, the margin for error is small and the responsibility is significant.

Table of Contents

EV battery testing covers electrical performance, thermal behavior, mechanical durability, and safety under normal and fault conditions. It also confirms compliance with international standards and local regulations. For contractors, this process affects project approvals, insurance requirements, and long-term liability. For engineers, it ensures that systems meet design intent and operate reliably in real-world conditions.

Understanding how EV battery testing works, which standards apply, what methods are used, and how much it costs helps professionals make informed decisions at every project stage.

Why EV Battery Testing Matters in Real Projects

Modern EV battery packs store large amounts of energy in compact spaces. A failure can lead to fire, explosion, toxic gas release, or total system loss. EV battery testing reduces these risks by verifying that cells, modules, and packs behave safely under electrical, thermal, and mechanical stress.

From a contractor’s perspective, Electric Vehicle battery testing is often tied to:

- Project handover approvals

- Warranty validation

- Insurance compliance

- Grid interconnection requirements

- Workplace safety certification

For engineers, EV battery testing confirms performance metrics such as capacity, internal resistance, cycle life, and thermal stability. It also supports design validation for battery management systems, cooling systems, and protective devices.

Without structured Electric Vehicle battery testing, installations may fail inspections or operate with hidden defects that surface later as costly failures.

Try our free online tool today ev charger cable size calculator

Key International Standards for EV Battery Testing

Several global standards define how Electric Vehicle battery testing must be conducted. These standards guide laboratories, manufacturers, and certification bodies.

| Standard | Organization | Main Focus | Application Area |

|---|---|---|---|

| UN 38.3 | United Nations | Transport safety testing | Cell and pack shipping approval |

| IEC 62660 | IEC | Performance and reliability of lithium-ion cells | Automotive traction batteries |

| ISO 12405 | ISO | Test procedures for battery packs and systems | EV battery system validation |

| SAE J2464 | SAE | Abuse testing and safety evaluation | North American EV safety testing |

| UL 2580 | UL | Safety of EV battery systems | Certification for road vehicles |

| IEC 62133 | IEC | Safety of portable sealed cells | Cell-level safety compliance |

Engineers must align EV battery testing plans with the correct standard depending on the project scope. A battery intended for road vehicles follows different requirements than one used in stationary energy storage linked to EV charging infrastructure.

Types of EV Battery Testing

Electric Vehicle battery testing can be grouped into performance, environmental, safety, and durability categories. Each category targets specific failure modes and operational limits.

Find out more about home ev charging station installation

Performance Testing

Performance-focused EV battery testing measures how well the battery delivers energy and power.

- Capacity testing confirms ampere-hour rating under defined discharge conditions

- Energy efficiency testing evaluates charge and discharge losses

- Power capability testing measures peak current output

- Internal resistance testing indicates aging and performance decline

These tests help engineers validate system sizing and predict vehicle range or duty cycle capability.

Environmental Testing

Electric Vehicle battery testing must simulate real-world environmental conditions.

| Test Type | Purpose | Typical Conditions |

|---|---|---|

| Thermal cycling | Detect expansion and contraction stress | -40°C to +85°C |

| High temperature storage | Assess degradation at heat | 60°C to 80°C |

| Humidity exposure | Check moisture resistance | 95% RH at elevated temp |

| Altitude simulation | Evaluate low-pressure behavior | Reduced atmospheric pressure |

Environmental Electric Vehicle battery testing ensures reliable operation in extreme climates and transport conditions.

Explore details on ev battery degradation calculator

Safety and Abuse Testing

Safety-focused EV battery testing examines behavior during abnormal or fault scenarios.

- Overcharge testing checks protection against excessive voltage

- Short circuit testing evaluates thermal runaway risk

- Nail penetration testing simulates internal cell damage

- Crush testing replicates mechanical impact

- Fire exposure testing assesses flame propagation

These procedures are critical for compliance and risk mitigation in EV battery testing programs.

Mechanical and Durability Testing

Mechanical Electric Vehicle battery testing verifies that vibration, shock, and long-term use do not degrade the battery.

| Test | Purpose | Typical Industry Use |

|---|---|---|

| Vibration testing | Simulates road and transport vibration | Vehicle-mounted packs |

| Mechanical shock | Replicates sudden impacts | Crash-related assessment |

| Cycle life testing | Measures long-term aging | Warranty validation |

| Drop testing | Assesses handling damage risk | Module-level testing |

Durability-focused EV battery testing helps determine expected service life and maintenance intervals.

Dive deeper into ev charger not working

Electric Vehicle Battery Testing Methods Used in Laboratories

Professional EV battery testing relies on specialized equipment and controlled environments.

Electrical Testing Equipment

Engineers use battery cyclers to charge and discharge packs under programmable conditions. These systems record voltage, current, temperature, and capacity over thousands of cycles. Data from EV battery testing supports performance modeling and warranty projections.

Thermal Chambers

Temperature-controlled chambers are used in Electric Vehicle battery testing to simulate hot and cold climates. These chambers allow engineers to monitor performance degradation and safety responses under extreme thermal stress.

Data Acquisition Systems

Modern EV battery testing involves high-speed data logging. Parameters such as cell voltage imbalance, temperature gradients, and current spikes are recorded and analyzed. This data helps identify early failure indicators.

Uncover insights on ev charger for hotels

Safety Monitoring Systems

During abuse-related Electric Vehicle battery testing, labs use gas detection, thermal cameras, and explosion-resistant chambers. These systems protect personnel and capture detailed failure data for engineering analysis.

Field Testing vs Laboratory EV Battery Testing

Not all Electric Vehicle battery testing happens in labs. Field testing plays a role, especially for contractors and system integrators.

| Aspect | Laboratory Testing | Field Testing |

|---|---|---|

| Environment | Controlled | Real-world conditions |

| Purpose | Certification and validation | Operational performance verification |

| Equipment | Specialized and calibrated | Portable test tools |

| Data accuracy | Very high | Moderate but practical |

Field EV battery testing may include insulation resistance checks, BMS diagnostics, thermal imaging, and load testing during commissioning.

Use our online tool EV Range Calculator: Instantly Estimate Your Electric Car Driving Distance

Compliance and Certification Process

Compliance in Electric Vehicle battery testing involves documentation, witnessed testing, and certification reports. Engineers must maintain clear test records, including procedures, equipment calibration certificates, and raw data logs.

Certification bodies review EV battery testing results to confirm alignment with standards such as UL, IEC, or ISO. Contractors should ensure that:

- Test reports come from accredited laboratories

- Serial numbers match installed equipment

- Installation conditions follow tested configurations

Non-compliance discovered after installation can lead to costly rework and delays.

Typical Costs of EV Battery Testing

Electric Vehicle battery testing costs vary widely based on battery size, required standards, and test depth.

| Testing Scope | Estimated Cost Range | Notes |

|---|---|---|

| Cell-level testing | $5,000 – $25,000 | Basic safety and performance |

| Module testing | $20,000 – $80,000 | Includes environmental tests |

| Full pack certification | $100,000 – $500,000+ | Abuse, transport, and safety tests |

| Cycle life testing | High due to long duration | Months of continuous testing |

Costs in EV battery testing increase with complexity, number of samples, and destructive test requirements. Planning early helps avoid repeated testing expenses.

Know more about EV Battery Types Explained for Professionals: Standards, Safety, Costs, and Performance Comparison

Role of Battery Management Systems in EV Battery Testing

The battery management system plays a major role in EV battery testing. It controls cell balancing, temperature monitoring, overcurrent protection, and fault detection. During EV battery testing, engineers verify that the BMS responds correctly to abnormal conditions.

Tests often include simulated sensor failures, communication loss, and overvoltage scenarios. Proper Electric Vehicle battery testing confirms that protective actions trigger before hazardous conditions develop.

Documentation Required for EV Battery Testing Projects

Accurate documentation supports regulatory approval and future audits.

Key documents include:

- Test plans aligned with applicable standards

- Calibration certificates for test equipment

- Raw data logs and summary reports

- Failure analysis reports if incidents occur

- Compliance declarations and certificates

Well-organized records simplify project approvals and reduce legal exposure for contractors.

Common Challenges in EV Battery Testing

Engineers and contractors often face practical issues during EV battery testing.

- Long test durations for cycle life validation

- High cost of destructive safety tests

- Limited availability of accredited laboratories

- Rapid technology changes requiring updated procedures

Planning Electric Vehicle battery testing early in the design phase helps manage these challenges and avoid project delays.

Explore everything about Electric Vehicle Battery Replacement Cost: Real Prices, Lifespan & Smart Savings in 2026

Best Practices for Engineers and Contractors

Professionals involved in EV battery testing can improve outcomes by following proven practices.

- Align test requirements with end-use application early

- Use accredited laboratories with relevant experience

- Verify that tested configurations match field installations

- Include safety margins beyond minimum standard limits

- Maintain clear traceability between components and reports

These steps ensure that Electric Vehicle battery testing supports both compliance and long-term reliability.

Future Trends in EV Battery Testing

As battery technology evolves, EV battery testing continues to expand. Solid-state batteries, higher voltage systems, and fast-charging capabilities introduce new testing demands. Thermal runaway propagation testing and advanced fire resistance evaluation are becoming more important.

Digital twins and advanced modeling are also being integrated with physical Electric Vehicle battery testing. This approach helps reduce development time while maintaining safety validation.

Use our online tool for free EV Charger Breaker and Wire Size Calculator: Instantly Determine Safe Charging Setup

Conclusion

EV battery testing is a foundational requirement for safe, compliant, and reliable electric vehicle systems. Engineers depend on structured Electric Vehicle battery testing to validate performance and durability, while contractors rely on it to meet regulatory and insurance requirements. From international standards and laboratory methods to field checks and certification processes, every stage of EV battery testing plays a role in risk reduction and quality assurance.

Understanding testing categories, costs, documentation, and compliance pathways allows professionals to plan effectively and avoid costly delays. As battery technologies continue to advance, Electric Vehicle battery testing will remain a critical discipline that supports innovation while protecting people, property, and infrastructure.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#EVBatteryTesting, #BatteryTestingStandards, #ElectricVehicleSafety, #LithiumIonTesting, #EVBatteryCompliance, #BatteryPerformanceTesting, #EVEngineering, #BatteryCertification, #EnergyStorageTesting, #EVServiceProfessionals