Electrical Switchgear Cost Estimate Guide for Accurate Project Budgeting and Industrial Power Planning

Accurate project budgeting starts with a reliable electrical switchgear cost estimate. Whether you are planning a new industrial facility, expanding a manufacturing plant, or upgrading an aging power distribution system, switchgear represents a significant portion of your capital expenditure. A miscalculation at this stage can affect procurement timelines, installation schedules, and overall return on investment.

Table of Contents

An electrical switchgear cost estimate is not just about pricing panels and circuit breakers. It involves equipment ratings, protection schemes, installation complexity, compliance standards, and long-term operational considerations. Engineers, project managers, and procurement teams must understand both technical and commercial aspects to develop a realistic budget.

This guide explains how to prepare an accurate electrical switchgear cost estimate for industrial power planning, covering major cost drivers, budgeting methods, and practical examples from real-world projects.

Understanding Electrical Switchgear in Industrial Projects

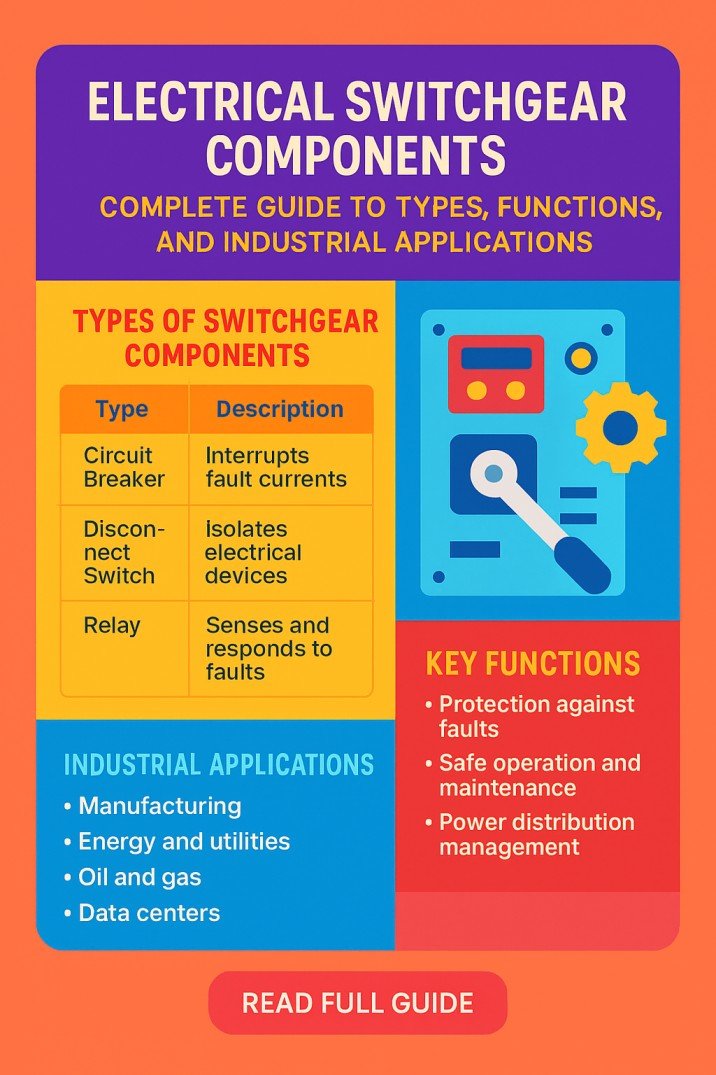

Switchgear is the heart of any electrical distribution system. It includes circuit breakers, disconnect switches, protective relays, busbars, metering devices, and control panels. In industrial environments, switchgear ensures safe operation, fault isolation, and continuity of service.

Know more about Industrial Control Panel Design Software – Best Tools, Features & Pro Tips for Engineers

Switchgear systems are typically classified as:

- Low voltage switchgear (up to 1 kV)

- Medium voltage switchgear (1 kV to 36 kV or higher)

- Gas-insulated switchgear (GIS)

- Air-insulated switchgear (AIS)

- Metal-clad or metal-enclosed assemblies

Each type has a different cost structure. A proper electrical switchgear cost estimate must align with voltage level, fault rating, short circuit capacity, and application type such as utility substation, process plant, or commercial building.

Key Factors That Influence Electrical Switchgear Cost Estimate

Several technical and commercial parameters affect your final electrical switchgear cost estimate. Ignoring even one of them can distort your project budget.

Voltage Level and Current Rating

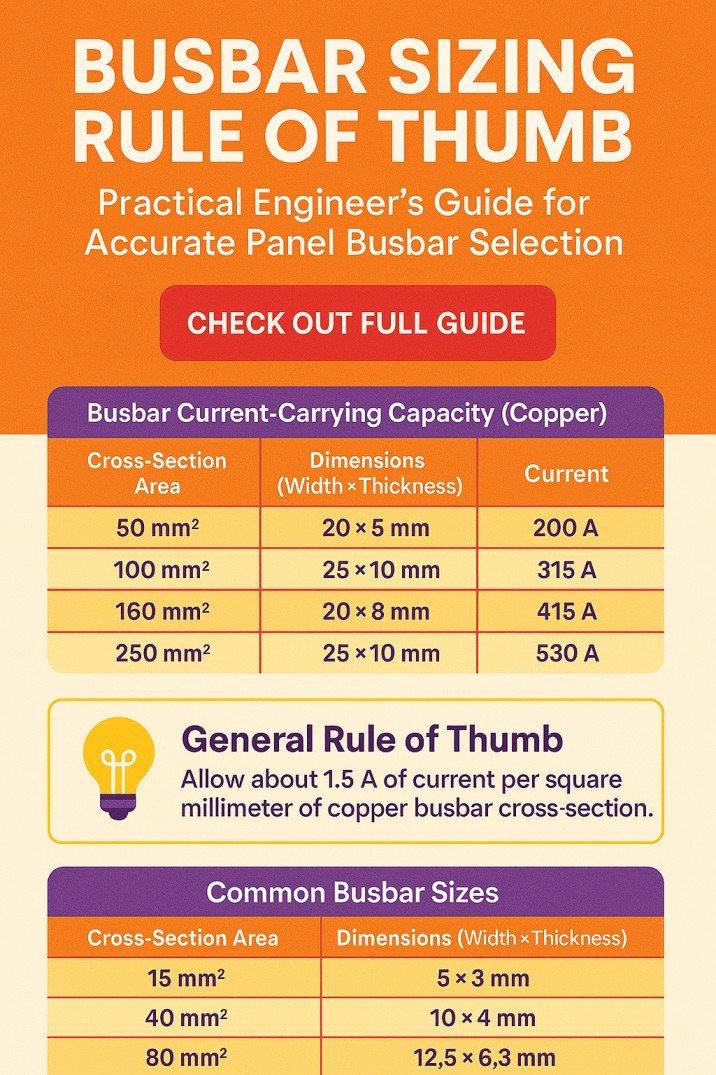

Higher voltage and current ratings require larger insulation clearances, stronger busbars, and higher interrupting capacity breakers. For example, a 400V, 3200A low voltage panel will cost significantly less than a 11kV, 2500A metal-clad switchgear lineup.

Use our online tool for free Wire Size Calculator for Subpanels and Feeders – NEC Guidelines Included

Short Circuit Withstand Rating

Industrial facilities often have high fault levels due to large transformers and generators. A 50kA short circuit rating panel costs more than a 25kA rated assembly because of reinforced bus systems and heavy-duty breakers.

Number of Incoming and Outgoing Feeders

More feeders mean more breakers, CTs, PTs, protection relays, and metering devices. Each additional feeder increases material and wiring costs.

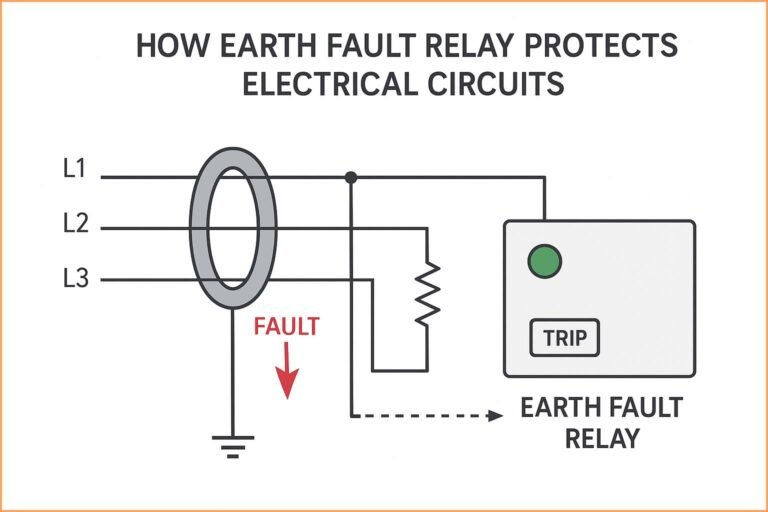

Protection and Control Scheme

Basic overcurrent protection is economical. However, advanced protection with numerical relays, communication modules, SCADA integration, and arc flash detection increases the electrical switchgear cost estimate.

Compliance Standards

Switchgear designed as per IEC, ANSI, IEEE, or UL standards may vary in price. Type-tested assemblies and certified equipment generally carry higher upfront costs but reduce long-term risk.

Know more about mcc panel design software

Typical Cost Breakdown of Switchgear System

A realistic electrical switchgear cost estimate should separate equipment cost from installation and indirect expenses.

Below is a general cost distribution for industrial projects:

| Cost Component | Approximate Percentage of Total Cost |

|---|---|

| Switchgear Panels and Breakers | 40% – 55% |

| Protection Relays and Metering | 5% – 10% |

| Busbars and Internal Wiring | 5% – 8% |

| Installation and Erection | 10% – 15% |

| Testing and Commissioning | 5% – 8% |

| Engineering and Design | 5% – 10% |

| Civil Works and Foundations | 5% – 10% |

These percentages vary depending on project scale and location. For retrofit projects, installation costs can be higher due to shutdown planning and cable modifications.

Explore everything about electrical control panel design training

Low Voltage vs Medium Voltage Switchgear Cost Comparison

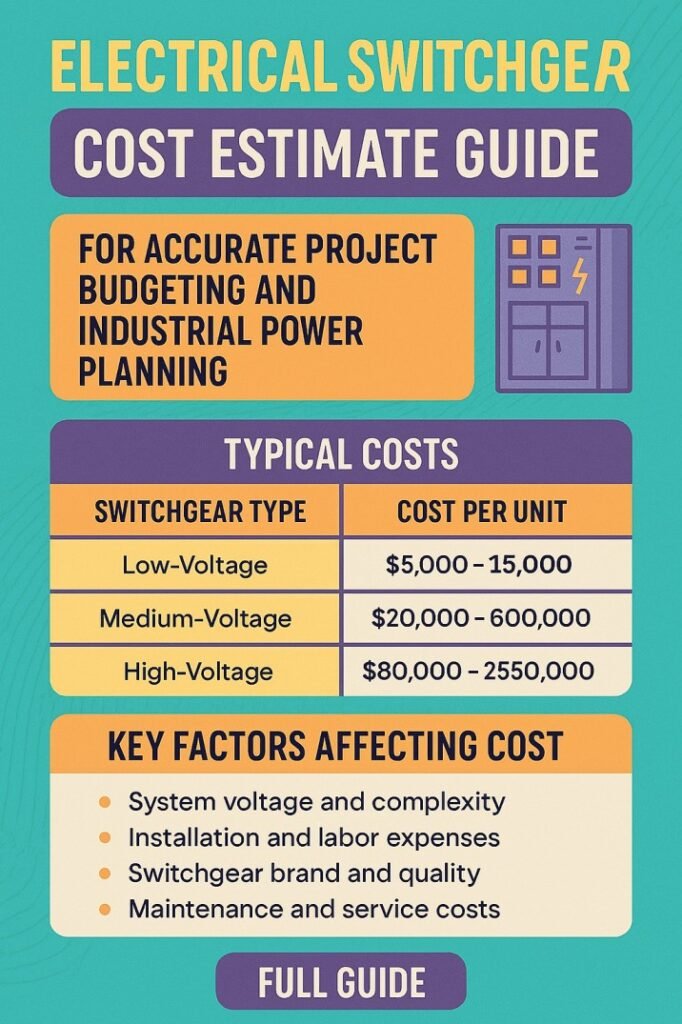

To prepare a reliable electrical switchgear cost estimate, it helps to compare typical price ranges. The table below provides indicative costs. Actual prices depend on region, manufacturer, and technical specifications.

| Switchgear Type | Typical Voltage | Estimated Cost Range (USD) per Panel |

|---|---|---|

| Low Voltage Panel (800A–3200A) | 400V–690V | 5,000 – 25,000 |

| MCC Panel (Motor Control Center) | 400V–690V | 8,000 – 40,000 |

| Medium Voltage AIS | 11kV–33kV | 25,000 – 120,000 |

| Gas Insulated Switchgear (GIS) | 11kV–33kV | 50,000 – 200,000 |

For large industrial plants, a complete lineup may consist of multiple panels, increasing the total electrical switchgear cost estimate into hundreds of thousands or even millions of dollars.

Know more about GIS vs AIS Switchgear: Best Key Differences Every Electrical Engineer Must Know

Step-by-Step Approach to Electrical Switchgear Cost Estimate

Accurate budgeting requires a structured methodology. The following approach is commonly used in EPC and industrial power projects.

1. Define Load Requirements

Start with load calculation and demand analysis. Determine connected load, diversity factor, and future expansion allowance. This defines breaker sizes and busbar ratings.

2. Determine Fault Level

Conduct short circuit analysis to identify fault current at each bus. This step is critical for selecting interrupting capacity and ensuring safety compliance.

3. Select Switchgear Type

Choose between air-insulated and gas-insulated designs based on space availability, environmental conditions, and reliability requirements.

Find more about Low Voltage Switchgear vs Medium Voltage Switchgear: Important Differences Every Engineer Must Know

4. Prepare Single Line Diagram

A detailed single line diagram shows incoming feeders, outgoing feeders, transformers, generators, and protection devices. It forms the technical basis of your electrical switchgear cost estimate.

5. Obtain Budgetary Quotations

Request preliminary quotations from approved manufacturers. At early project stages, use budgetary pricing based on similar completed projects.

6. Add Installation and Indirect Costs

Include cable termination, civil foundation, earthing system, HVAC for electrical rooms, and commissioning support.

Example Calculation for Industrial Plant

Consider a manufacturing facility requiring:

- One 11kV incoming feeder

- Two transformer feeders

- Eight outgoing feeders

- Fault level of 40kA

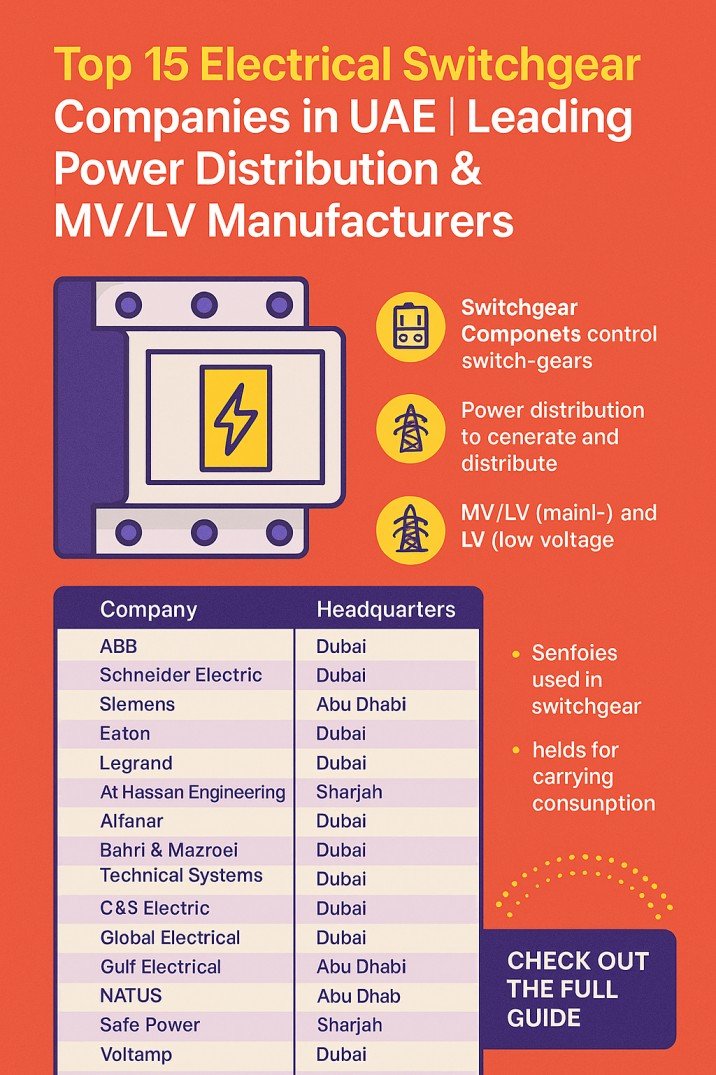

Find all about Top 15 Medium Voltage Switchgear Manufacturers in UAE: Ultimate Guide for Engineers & Buyers

Based on market averages:

| Item | Quantity | Unit Cost (USD) | Total (USD) |

|---|---|---|---|

| 11kV Incoming Panel | 1 | 60,000 | 60,000 |

| 11kV Transformer Feeders | 2 | 45,000 | 90,000 |

| 11kV Outgoing Feeders | 8 | 35,000 | 280,000 |

| Engineering and Design (8%) | – | – | 34,400 |

| Installation and Commissioning (12%) | – | – | 51,600 |

| Total Estimated Cost | – | – | 516,000 |

In this case, the electrical switchgear cost estimate for medium voltage distribution is approximately 516,000 USD. This does not include transformers or downstream low voltage panels.

Hidden Costs Often Overlooked

Many projects underestimate the true electrical switchgear cost estimate because they ignore indirect elements.

Commonly overlooked costs include:

- Arc flash mitigation systems

- Remote racking mechanisms

- Spare breakers

- Extended warranty packages

- Shipping and insurance

- Import duties and taxes

- On-site supervision charges

Use our online tool for free Sub Panel Breaker Size Calculator – Find the Right Breaker for Your Electrical Sub Panel

Including contingency of 5% to 10% is advisable, especially in volatile markets.

Strategies to Optimize Electrical Switchgear Cost Estimate

Cost optimization does not mean compromising safety. It involves technical decisions that reduce capital expenditure without reducing reliability.

Standardize panel ratings where possible. Avoid oversizing breakers unnecessarily. Consider modular switchgear designs for phased expansion. Evaluate total cost of ownership, not just purchase price.

Early coordination between electrical engineers and procurement teams helps refine the electrical switchgear cost estimate and prevent late-stage design changes.

Lifecycle Cost Consideration

A comprehensive electrical switchgear cost estimate should consider operational expenses over 20 to 25 years. Maintenance, spare parts, energy losses, and downtime risk contribute to lifecycle cost.

Although gas-insulated switchgear has higher upfront cost, it requires less maintenance and space. In high-value industrial environments, this may justify the higher investment.

Use our online tool for free Sub Panel Sizing Calculator: Best Tool to Use

Final Thoughts on Accurate Budget Planning

Developing an accurate electrical switchgear cost estimate is a technical and strategic process. It combines load analysis, fault studies, protection design, vendor pricing, and installation planning. For industrial power planning, switchgear is not just another line item. It defines system reliability, safety, and operational continuity.

By following a structured approach and considering both direct and indirect costs, engineers can prepare realistic budgets and avoid financial surprises during project execution. Whether the project is a small commercial facility or a large industrial plant, a well-prepared electrical switchgear cost estimate ensures confident decision-making and successful power system implementation.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#ElectricalSwitchgearCostEstimate, #SwitchgearPricing, #ElectricalProjectEstimation, #PowerDistributionCost, #SwitchgearBudgeting, #ElectricalEngineering, #SubstationCosting, #IndustrialElectrical, #MVSwitchgear, #ElectricalContractors