Earthing Cable Size Calculation Formula

Introduction

In electrical systems, the earthing (or grounding) cable plays a vital role in ensuring safety and stability. When a fault occurs, the earthing cable provides a low-resistance path to dissipate the excess current into the ground, protecting both people and equipment. Proper calculation of the earthing cable size is essential, as an undersized cable can lead to dangerous conditions. In this article, we’ll explore the earthing cable size calculation formula along with practical steps and factors to consider. Understanding this process will help you select the right cable size, ensuring optimal safety and compliance with industry standards.

Table of Contents

What is Earthing Cable Size Calculation?

Earthing cable size calculation is the process of determining the correct cable size to handle the fault current safely without overheating.

Various factors influence this calculation, such as fault current magnitude, soil resistivity, and the cable’s thermal capacity. By following the appropriate earthing cable size calculation formula, you can ensure that your system is safe and reliable.

Factors Influencing Earthing Cable Size

- Fault Current: The peak current that flows during a fault affects the cable size.

- Duration of Fault: The time taken to clear the fault impacts the thermal stress on the cable.

- Soil Resistivity: Soil resistance affects heat dissipation; higher resistivity requires larger cables.

- Material of Cable: Different materials (e.g., copper or aluminum) affect the thermal capacity.

- Thermal Resistivity: The cable’s ability to dissipate heat safely influences sizing.

Earthing Cable Size Calculation Formula

The general formula to calculate earthing cable size is based on the heat generated during a fault. The formula is as follows:

Formula:

Where:

- A= Minimum cross-sectional area of the earthing conductor (in mm²)

- I = Fault current in amperes (A)

- t = Duration of fault in seconds (s)

- K = Constant based on material and insulation type

Explanation of Each Parameter:

- I (Fault Current): Calculated using the system voltage and impedance.

- t (Duration): Typically defined by protective devices and fault-clearing time.

- K (Material Constant): Dependent on the conductor material (e.g., copper or aluminum) and insulation type.

Note: Use our online electrical load calculator for electrical load calculation here. You can also use voltage drop calculator for voltage drop calculation for cable selection in any single and three phase circuit here. Further explore our online electrical calculators to design your electrical systems in an efficient way.

Step-by-Step Earthing Cable Size Calculation

Step 1: Determine Fault Current (I)

Calculate the expected fault current using the short-circuit calculation based on your system’s voltage and impedance.

Step 2: Define Fault Duration (t)

Identify the fault-clearing time, which is typically provided by the circuit protection devices. Commonly used values range from 0.1 to 1 second, depending on the system requirements.

Step 3: Use the Material Constant (K)

The constant K varies based on the conductor material:

- For Copper: 143 (standard insulation)

- For Aluminum: 94 (standard insulation)

Step 4: Calculate Cross-Sectional Area (A)

Using the values obtained, substitute them into the earthing cable size calculation formula to find the minimum cross-sectional area:

This calculation provides the minimum cross-sectional area required to ensure the cable can handle the fault current safely.

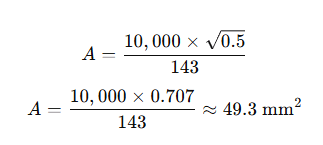

Practical Example: Earthing Cable Size Calculation

Let’s go through a practical example:

- Given Data:

- Fault Current (I) = 10,000 A

- Duration (t) = 0.5 seconds

- Material Constant for Copper (K) = 143

- Calculation:

This result suggests a minimum cross-sectional area of 50 mm² for a copper earthing cable to handle a fault current of 10,000 A for 0.5 seconds.

Guidelines for Selecting Earthing Cable Size

Safety Margin: Always choose a cable with a slightly higher size than calculated for added safety.

Check Compliance: Ensure the calculated size complies with national or local regulations, such as IEC standards.

Material Choice: Copper is generally preferred for earthing due to its superior conductivity and durability.

Environmental Conditions: Consider factors like soil temperature and moisture, which can affect cable performance.

Common Mistakes in Earthing Cable Sizing

Ignoring Fault Duration: The fault duration impacts thermal stress, so always include it in calculations.

Underestimating Fault Current: Use accurate short-circuit values to avoid under-sizing cables.

Neglecting Soil Resistivity: High soil resistivity may require larger cables or additional grounding electrodes.

Overlooking Standards: Following IEC or local standards is critical to ensure safety and regulatory compliance. We can easily determine the earthing cable size as per IEC using this guide.

Conclusion

Calculating the right earthing cable size is a critical step in ensuring electrical safety. By following the earthing cable size calculation formula and understanding the factors involved, you can design a grounding system that protects both people and equipment from electrical faults. Always remember to double-check your calculations, choose the appropriate material, and verify compliance with local standards. With the right approach, you’ll create a safer and more reliable electrical system.

Follow us on LinkedIn”Electrical Insights” to get the latest updates in Electrical Engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.

Worth Read Posts

EarthingCableSize, #EarthingCalculation, #ElectricalEngineering, #CableSizing, #GroundingSystem, #EarthingGuide, #ElectricalSafety, #EarthCableSize, #ElectriciansGuide, #PowerSystemDesign, #CableSizeCalculation, #ElectricalInstallation, #GroundingCable, #SafeElectricalSystems, #EarthingStandards