Difference Between Demand Factor and Power Factor

In the world of electrical engineering, terms like demand factor and power factor are frequently used. While they may seem similar, they refer to very different concepts. Understanding the difference between demand factor and power factor is crucial for professionals in the field of electrical design, energy management, and system optimization. In this article, we will explore these concepts, providing technical insights, definitions, applications, and key differences between them.

What is Demand Factor?

The demand factor refers to the ratio of the maximum demand of a system to the total connected load. In simpler terms, it indicates how much of the total installed capacity is being used at any given time. The demand factor is an essential parameter for determining the size of electrical equipment and the overall efficiency of a system.

For example, in a residential setting, if the total installed capacity of all appliances is 10 kW, but at any given time, only 4 kW is being used, the demand factor would be 0.4. A lower demand factor generally indicates more efficient usage of electrical resources, as it means the system is not running at full capacity all the time.

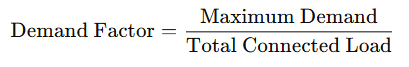

Formula for Demand Factor

The formula for calculating the demand factor is straightforward:

Where:

- Maximum Demand refers to the highest level of power consumption recorded in a given time period.

- Total Connected Load is the sum of the power ratings of all equipment and devices in the system.

What is Power Factor?

Power factor is the ratio of real power (active power) to apparent power in an electrical circuit. It is a dimensionless number between 0 and 1, representing how efficiently the electrical power is being converted into useful work. A power factor of 1 (or unity) indicates that all the power supplied is being used effectively, while a lower power factor suggests inefficiencies in the system.

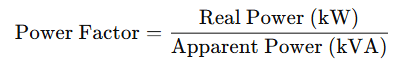

Formula for Power Factor

The formula to calculate power factor is:

Where:

- Real Power is the actual power consumed by the system, measured in kilowatts (kW).

- Apparent Power is the total power supplied by the source, measured in kilovolt-amperes (kVA).

A power factor closer to 1 indicates efficient power usage, while a value much lower than 1 suggests that a large portion of the energy is wasted due to reactive power.

Key Differences Between Demand Factor and Power Factor

1. Definition

The first and most basic difference between demand factor and power factor lies in their definitions. The demand factor refers to the ratio of peak demand to connected load, essentially measuring the efficiency of the system in utilizing its installed capacity. On the other hand, the power factor measures the efficiency of electrical power usage by calculating how much real power is being used compared to the total power supplied.

2. Units of Measurement

Demand factor is a unitless number, expressed as a ratio. It compares the actual demand to the total connected load and thus doesn’t have specific units.

Power factor is also a unitless number, but it’s specifically a ratio of real power to apparent power. Apparent power is measured in kVA, while real power is measured in kW.

3. Focus Areas

The demand factor focuses on the load utilization aspect. It deals with the total electrical capacity that is being used at peak demand.

In contrast, the power factor is concerned with the quality of the electrical power being used. It assesses how much of the energy is being effectively converted into useful work and how much is wasted due to reactive power.

4. Applications

Demand factor plays a crucial role in electrical system design. It helps in sizing transformers, generators, and other equipment to ensure that the system can handle peak loads efficiently. It is also used for billing purposes in commercial and industrial settings to determine how much power is needed during peak times.

Power factor is crucial in the analysis of energy efficiency. A low power factor can lead to higher utility bills, as utilities often charge additional fees for low power factor, requiring them to supply more apparent power to meet demand. It’s particularly important in systems with inductive loads, such as motors and transformers, where reactive power causes inefficiencies.

5. Impact on Electrical Systems

A high demand factor indicates that a system is not using all of its capacity, which can imply over-sizing of equipment and wasted investment. Conversely, a low demand factor suggests that the system is under-utilized, potentially leading to unnecessary energy costs.

A low power factor, on the other hand, can lead to overloading of equipment and inefficient energy use. It can also increase the cost of electricity, as utilities may require additional infrastructure to supply the excess apparent power.

6. Calculation and Formulas

While both demand factor and power factor are calculated using ratios, they differ significantly in their formulas and the data used.

| Parameter | Demand Factor | Power Factor |

|---|---|---|

| Formula | Maximum Demand / Total Connected Load | Real Power (kW) / Apparent Power (kVA) |

| Focus | Load utilization efficiency | Power efficiency (active vs. apparent) |

| Impact on System Design | Sizing of electrical equipment and capacity | Energy efficiency, reduction in losses |

7. Typical Values

- Demand Factor:

- For residential systems, the demand factor generally ranges from 0.4 to 0.6.

- For commercial systems, it can range from 0.6 to 0.8.

- For industrial systems, the demand factor may range from 0.7 to 1.0.

- Power Factor:

- An ideal power factor is 1, indicating that all the power is being used effectively.

- Industrial systems often have a power factor ranging from 0.8 to 0.9.

- A value below 0.8 is considered poor and inefficient.

Why Do Demand Factor and Power Factor Matter?

Both demand factor and power factor have a significant impact on the operation, cost, and efficiency of electrical systems. By understanding the difference between demand factor and power factor, engineers can design better systems that minimize waste, reduce costs, and optimize energy use. A high demand factor indicates that equipment may be oversized, while a low power factor means that energy is being wasted and system efficiency is compromised.

Optimizing both factors is essential for reducing electrical energy costs and improving the sustainability of energy usage. For instance, power factor correction devices, such as capacitors or synchronous condensers, can be used to improve power factor and reduce losses due to reactive power.

Conclusion

The difference between demand factor and power factor lies in their respective roles in evaluating the efficiency of electrical systems. While demand factor focuses on how efficiently the connected load is being used, power factor deals with the quality of the energy consumed. Understanding and optimizing both factors can lead to more efficient electrical system designs, reduced energy consumption, and lower operating costs.

By considering both the demand factor and power factor, engineers and energy managers can make informed decisions, ensuring that their systems are both cost-effective and energy-efficient.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#DemandFactor, #PowerFactor, #ElectricalEngineering, #EnergyManagement, #ElectricalLoad, #PowerSystems, #ElectricalEfficiency, #EnergyConsumption, #ElectricalCalculations, #PowerQuality, #EnergyOptimization, #PowerFactorCorrection, #DemandFactorCalculation, #EnergySustainability, #ElectricalSystems