Constant Torque VFD Fundamentals: Performance, Applications, and Key Benefits Explained

Variable Frequency Drives (VFDs) have revolutionized industrial motor control, offering efficiency, flexibility, and precision. Among various types, constant torque VFDs play a pivotal role in applications requiring steady torque across a wide speed range. Understanding Constant Torque VFD Fundamentals is crucial for engineers, technicians, and plant managers seeking optimal motor performance and energy efficiency.

Table of Contents

This article explores the performance characteristics, key applications, and benefits of constant torque VFDs in an easy-to-understand, comprehensive manner.

What is a Constant Torque VFD?

A constant torque VFD is a motor control device that maintains a consistent torque output irrespective of the motor’s speed. Unlike variable torque VFDs, where torque decreases at lower speeds, constant torque drives ensure full torque from zero speed up to the motor’s rated speed.

This feature makes them indispensable for applications like conveyors, mixers, extruders, and elevators. Constant torque VFDs achieve this by adjusting voltage and frequency simultaneously. At low speeds, the drive increases current to compensate for torque requirements, while at high speeds, it maintains a proportional voltage-to-frequency ratio to protect the motor and ensure stable operation.

Know more about Top 15 Variable Frequency Drive Manufacturers in USA

Constant Torque VFD Fundamentals

Key Characteristics

- Maintains torque consistently from zero to full speed

- Supports frequent start-stop operations

- Handles high inertia loads efficiently

- Reduces mechanical stress on equipment

| Feature | Description | Benefits |

|---|---|---|

| Torque Consistency | Full torque at all speeds | Reliable performance for conveyors and mixers |

| Energy Efficiency | Adjusts motor power to match load | Reduces energy costs |

| Smooth Operation | Minimizes mechanical shocks | Extends motor life |

| High Inertia Handling | Manages heavy loads effectively | Suitable for crushers and presses |

If you are troubleshooting VFD then this guide will certainly help What are Common VFD Troubleshooting Tips?

How Constant Torque VFDs Work

Understanding Constant Torque VFD Fundamentals involves looking at how these drives control motor speed and torque. The VFD converts incoming AC power to DC and then back to AC with variable frequency and voltage. This modulation allows precise control over motor speed while maintaining torque.

Step 1: The AC supply enters the drive and is rectified into DC.

Step 2: The inverter section converts DC back to AC with variable frequency.

Step 3: Voltage is modulated according to the desired speed to maintain constant torque.

This process ensures the motor provides full torque at startup and throughout the speed range, making it ideal for heavy-duty and continuous operation applications.

| Component | Function |

|---|---|

| Rectifier | Converts AC to DC |

| DC Bus | Stores and filters DC energy |

| Inverter | Converts DC back to AC with controlled frequency |

| Control Unit | Monitors speed, torque, and current for optimal operation |

Having a faulty VFD? Need repairing facilities the you must know Variable Frequency Drive Repairing Services Cost

Applications of Constant Torque VFDs

The versatility of constant torque VFDs allows them to serve in a wide range of industries. Here are some common applications:

- Conveyors and Material Handling: Ensures smooth transport without jerks, even at low speeds.

- Mixers and Agitators: Maintains uniform torque for consistent blending and mixing.

- Extruders and Crushers: Provides steady torque for processing viscous or dense materials.

- Pumps and Fans with Constant Torque Needs: Ensures stable operation in high-pressure systems.

- Elevators and Hoists: Guarantees safe and smooth lifting with consistent torque.

| Industry | Application | Benefit |

|---|---|---|

| Food & Beverage | Mixers, Conveyors | Consistent product quality |

| Plastics | Extruders, Injection Molding | Precise material shaping |

| Mining | Crushers, Conveyor Belts | Handles high inertia loads |

| HVAC | Pumps, Fans | Reduces energy consumption |

| Material Handling | Elevators, Hoists | Smooth and safe operation |

Advantages of Using Constant Torque VFDs

Investing in constant torque VFDs brings several tangible benefits, from energy savings to improved equipment lifespan.

- Energy Efficiency: Reduces unnecessary power consumption by matching motor output to load requirements.

- Improved Process Control: Precise speed and torque control ensures consistent product quality and operational stability.

- Reduced Mechanical Wear: Smooth acceleration and deceleration reduce stress on motors and mechanical components.

- Enhanced Safety: Reliable torque control prevents sudden drops or motor stalls in critical operations.

- Flexibility: Can be programmed for different torque-speed profiles to suit various industrial needs.

Find the cheapest Variable Frequency Drive Repairing Services in USA

| Benefit | Explanation | Impact |

|---|---|---|

| Energy Savings | Adjusts power to match load | Lower operational costs |

| Process Stability | Maintains consistent torque | Better product quality |

| Longevity | Reduces mechanical stress | Extended motor and equipment life |

| Safety | Prevents stalls and torque spikes | Safer working environment |

| Flexibility | Customizable speed-torque control | Adaptable to various industrial tasks |

Installation and Maintenance Considerations

Proper installation and maintenance are vital to fully leverage Constant Torque VFD Fundamentals. Follow these steps for optimal performance:

Step 1: Select the Right Drive – Match the VFD to the motor’s rated torque, speed, and application.

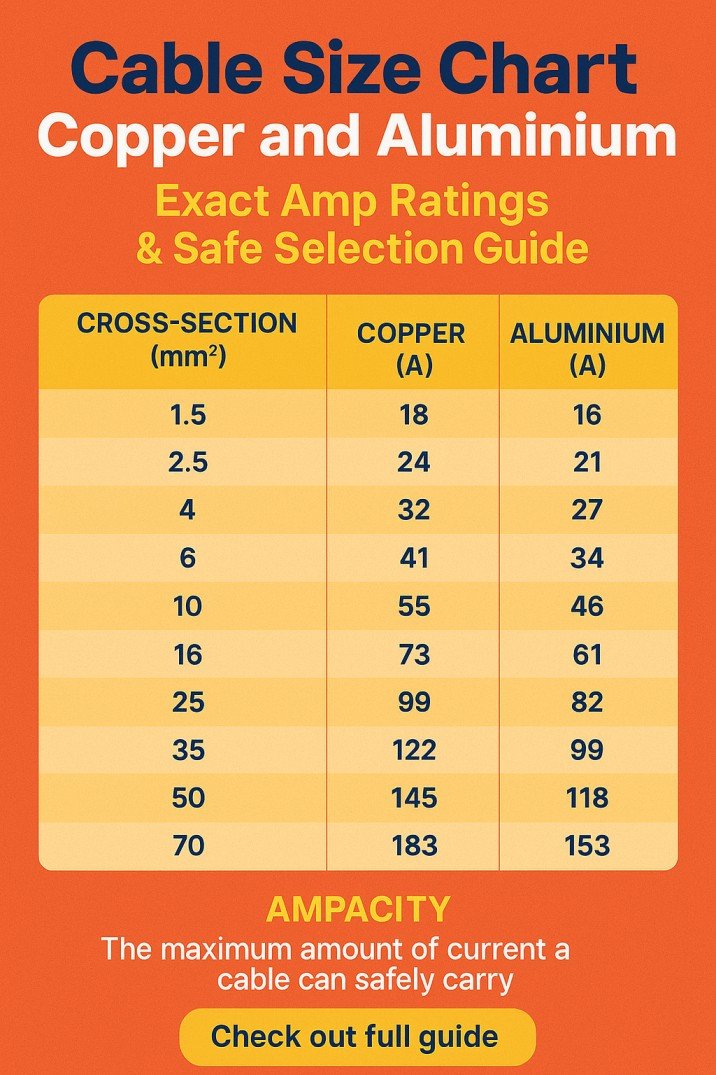

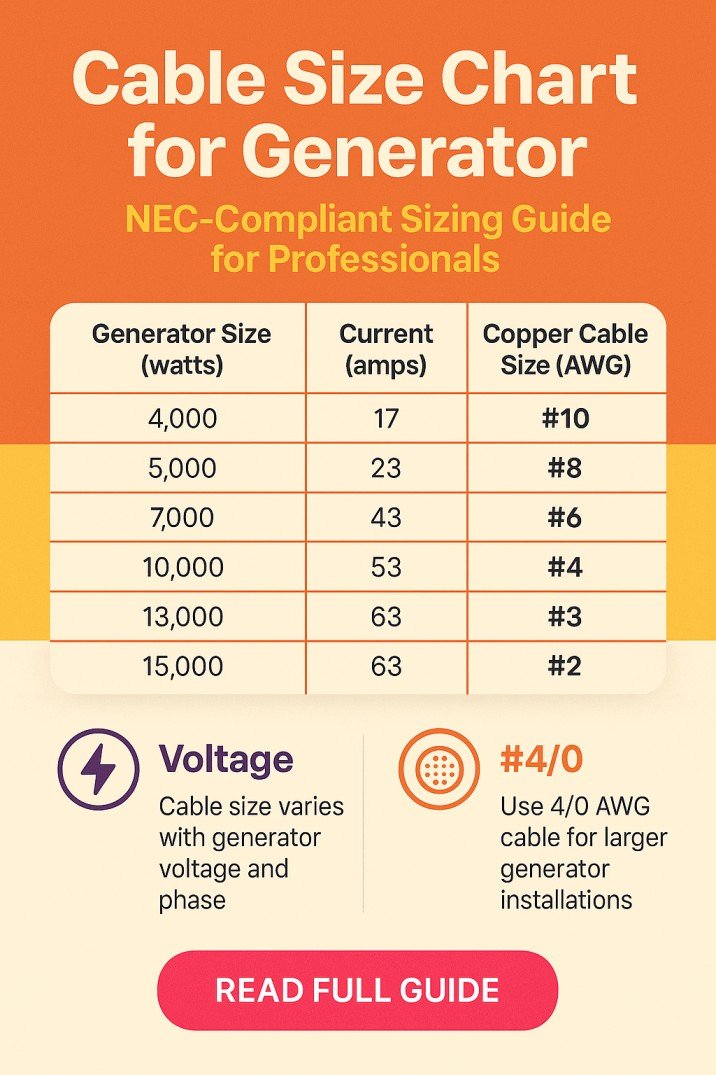

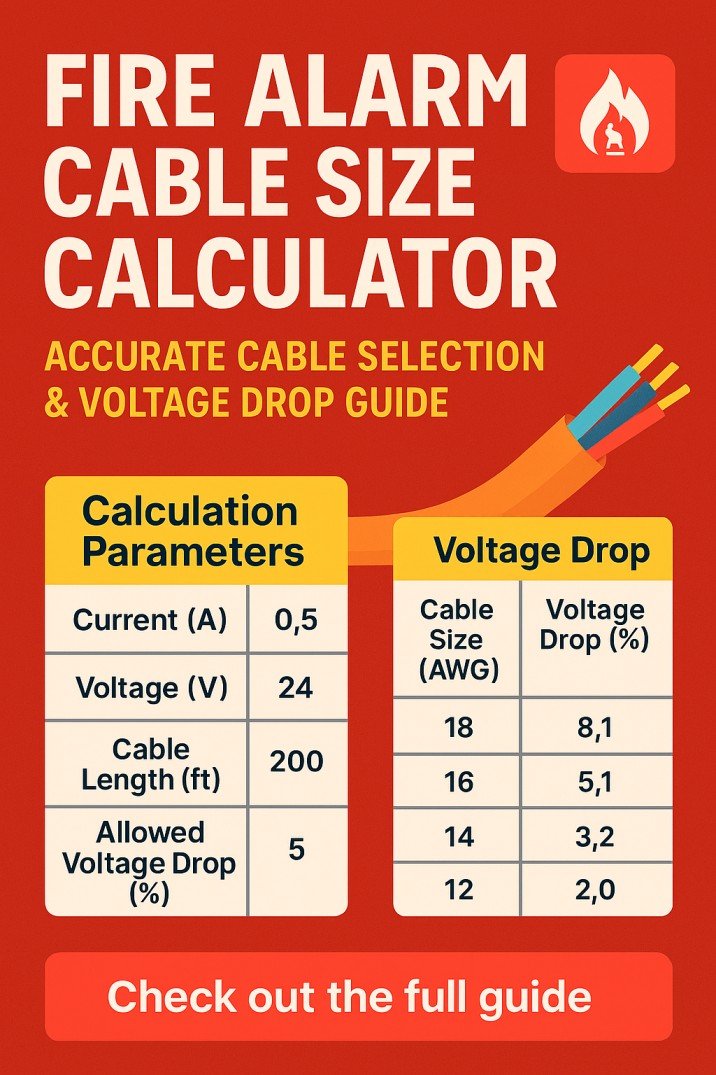

Step 2: Ensure Proper Wiring – Use appropriate cable size and grounding to prevent voltage drops and electrical noise.

Step 3: Program Parameters Correctly – Set acceleration, deceleration, and torque limits according to application requirements.

Step 4: Regular Maintenance – Clean filters, inspect connections, and check for overheating to prevent unexpected failures.

Step 5: Monitor Performance – Utilize built-in diagnostics to track load, current, and temperature for predictive maintenance.

Know more about How to Size a VFD for a Motor. This is an expert Guide for Accurate Selection

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Clean Filters | Monthly | Prevents overheating |

| Inspect Connections | Quarterly | Avoids voltage drop |

| Check Motor Current | Monthly | Detects overload early |

| Update Parameters | As needed | Ensures optimal operation |

| Monitor Drive Health | Continuous | Extends life of equipment |

Common Challenges and Solutions

While constant torque VFDs offer numerous benefits, some challenges may arise during operation:

- Overheating: Can occur in high ambient temperatures or if ventilation is poor. Solution: Install cooling fans and monitor temperature regularly.

- Harmonic Distortion: Large drives can cause power quality issues. Solution: Use filters or multi-pulse drives to reduce harmonics.

- Compatibility Issues: Older motors may not handle variable frequency well. Solution: Verify motor compatibility before installation.

Learn in detail on vfd overload current setting

| Challenge | Cause | Solution |

|---|---|---|

| Overheating | Poor ventilation | Add fans, monitor temperature |

| Harmonics | Large drives | Install harmonic filters |

| Motor Incompatibility | Old motors | Check motor specifications |

Key Takeaways

Understanding Constant Torque VFD Fundamentals is essential for anyone involved in motor-driven systems. These drives provide consistent torque, energy savings, and enhanced control across various industrial applications. By selecting the right drive, programming it properly, and maintaining it regularly, businesses can achieve long-term efficiency, reliability, and safety.

Constant torque VFDs are ideal for applications with steady torque requirements at all speeds, including conveyors, mixers, extruders, and elevators. The advantages of smooth operation, process control, energy efficiency, and equipment longevity make them a smart investment for industries aiming for operational excellence and reduced energy costs.

Explore the key standards related to VFDs here IEC Standards for Variable Frequency Drives

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#ConstantTorqueVFD,#VFDControl,#IndustrialDrives,#MotorTorque,#VariableFrequencyDrive,#MotorControlBasics,#ElectricalEngineering,#DriveTechnology,#AutomationSystems,#PowerElectronics