Bus Duct in Electrical System: Best Guide

The bus duct in electrical system is a critical component in modern power distribution. It offers a compact, flexible, and efficient method to carry large currents within buildings, factories, and power stations. Compared to traditional cabling, bus ducts provide higher safety, reduced power losses, and easier installation. These advantages make bus ducts popular in both commercial and industrial electrical infrastructures.

Understanding how a bus duct in electrical system works is essential for engineers, electricians, and facility managers. The system not only ensures effective power flow but also contributes to space optimization and improved energy efficiency.

What is Bus Duct in Electrical System

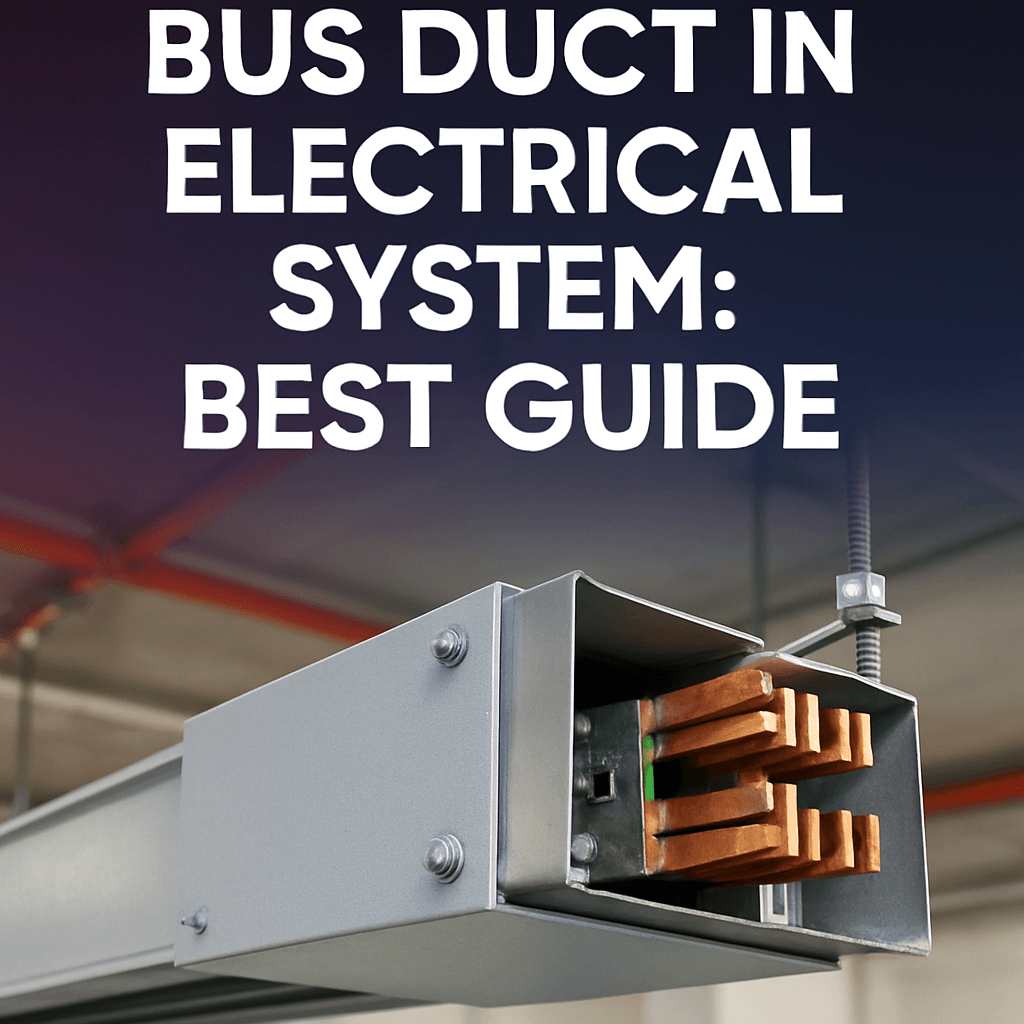

A bus duct in electrical system is a metallic enclosure that houses copper or aluminum bus bars. These bus bars are the conductors that carry electrical power from one point to another. The enclosure offers mechanical protection and electrical insulation.

Bus ducts come into play especially when high current needs to be transferred over short to medium distances. They are ideal for applications that demand safety, reliability, and space-saving layouts.

Bus ducts serve as alternatives to cable trays and conduit wiring systems. While cable systems are more common in residential installations, bus bar electrical solutions dominate in commercial and industrial setups due to their robust nature.

Technical Composition of Bus Duct in Electrical System

The bus duct in electrical system comprises the following primary components:

Conductors (Bus Bars): These are typically made of copper or aluminum. They are the current-carrying elements and can be of different shapes – rectangular, round, or even flat.

Insulation: The bus bars are insulated using air, epoxy resin, or other dielectric materials. This prevents short circuits and ensures operator safety.

Enclosure: This is the metallic body made of aluminum or galvanized steel that protects the bus bars from mechanical damage and environmental exposure.

Table: Typical Bus Duct Ratings and Parameters

| Parameter | Range |

|---|---|

| Voltage Rating | Up to 36 kV |

| Current Carrying Capacity | 400 A – 6000 A |

| Insulation Type | Air, Epoxy, Mylar, Polyester |

| Enclosure Material | Steel, Aluminum |

| Cooling Method | Air Natural or Forced |

Applications of Bus Duct in Electrical System

The bus duct in electrical system is widely used in:

- Power plants

- Substations

- Commercial buildings

- Industrial plants

- Data centers

- Shopping complexes

These applications often involve high current flows, making electrical bus bar systems more efficient than cable alternatives. The modular nature of bus ducts also allows for easy modifications during maintenance or system upgrades.

Types of Bus Duct in Electrical System

There are several types of bus bar systems based on installation and insulation methods. Choosing the right type depends on factors like power rating, installation environment, and layout.

Segregated Phase Bus Duct

This type has individual enclosures for each phase conductor. The physical separation improves electrical performance and reduces the risk of faults.

Non-Segregated Phase Bus Duct

All three phase conductors are enclosed in a single housing. This type is more compact and cost-effective but has higher chances of inter-phase faults.

Isolated Phase Bus Duct

Used for very high current applications, each phase conductor is placed in its own grounded enclosure with air gaps between them. This provides the best isolation and is often used in power plants.

Plug-In Bus Duct

This type allows tapping at different locations. Ideal for buildings and factories where equipment layout might change over time.

Sandwich Bus Duct

Here, conductors are enclosed between insulating layers, forming a “sandwich.” It is highly compact and suitable for indoor installations.

Advantages of Using Bus Duct in Electrical System

The bus duct in electrical system offers several advantages over traditional cable-based systems:

Space-Saving Design: Since the bus duct is compact and can be mounted overhead or vertically, it reduces the space required for electrical routing.

Improved Cooling: The open design allows for better air circulation, reducing the risk of overheating.

Ease of Maintenance: Bus ducts are modular, making it easier to replace damaged sections without overhauling the entire system.

Enhanced Safety: Enclosures and insulation minimize the risk of electrical accidents.

Lower Energy Loss: Due to lower impedance and higher conductivity, power losses are significantly reduced compared to traditional wiring.

Installation Guidelines for Bus Duct in Electrical System

Proper installation is critical for the safe operation of a bus duct in electrical system. Installers must ensure:

- Proper alignment of bus duct sections

- Secure connections at joints

- Grounding as per electrical standards

- Adequate ventilation for heat dissipation

Support brackets should be placed at regular intervals to prevent sagging or misalignment. The entire assembly must be tested for insulation resistance, continuity, and thermal performance before commissioning.

Maintenance Practices for Bus Duct in Electrical System

Periodic inspection is essential for the reliability of the bus duct in electrical system. Maintenance activities include:

- Checking for hot spots using thermal imaging

- Inspecting insulation for cracks or wear

- Tightening loose connections

- Cleaning the enclosure and terminals

Scheduled maintenance reduces downtime and extends the system’s lifespan.

Bus Duct vs. Cable System

| Feature | Bus Duct | Cable System |

|---|---|---|

| Space Requirement | Low | High |

| Installation Time | Faster | Slower |

| Maintenance | Easier | More complex |

| Power Loss | Low | Relatively higher |

| Cost | High initial, low long-term | Low initial, higher long-term |

| Flexibility | High (modular sections) | Medium |

Bus Duct Standards and Compliance

Bus ducts must comply with several international and national standards, including:

- IEC 61439 for low-voltage switchgear and controlgear assemblies

- ANSI/NEMA BU 1 for busways

- IS 8623 for factory-built assemblies in India

These standards ensure the bus duct in electrical system operates safely and reliably.

Future Trends in Bus Duct in Electrical System

The electrical industry is moving toward smarter, more efficient systems. Bus ducts are evolving with the integration of sensors and monitoring devices. These smart bus ducts provide real-time data on current, temperature, and fault detection.

The use of bus duct in electrical system is also increasing in sustainable energy setups. In solar farms and wind power stations, bus ducts help in centralized power collection and transmission.

Integration with IoT platforms is another future direction. Just as Smart Grid Technology in IoT connects devices and optimizes power flow, intelligent bus ducts will form part of automated energy management systems in modern buildings.

Factors to Consider Before Selecting Bus Duct in Electrical System

Before installing a bus duct in electrical system, several factors must be evaluated:

- Current Rating: The total load current must be considered along with future expansion.

- Environmental Conditions: Humidity, dust, and chemical exposure can affect insulation.

- Installation Path: Whether the layout is vertical, horizontal, or a mix influences the choice of design.

- Budget: Though initially costlier than cables, bus ducts reduce maintenance and power loss costs.

Understanding what is bus bar in electrical setups and how it integrates into overall system design is crucial for choosing the right bus duct solution.

Real-Life Examples of Bus Duct in Electrical System

- Data Centers: Here, bus ducts are used to supply power to server racks. The modular plug-in type offers flexibility in equipment arrangement.

- Industrial Plants: Heavy machines require high current, and bus ducts provide a safe and efficient solution.

- Commercial Buildings: Shopping malls and office complexes use bus ducts to distribute power across multiple floors.

In each case, bus ducts offer operational benefits that go beyond power delivery—they support energy management, ease of access, and scalability.

Conclusion

The bus duct in electrical system is a highly reliable, efficient, and scalable method of power distribution. It addresses the challenges of modern infrastructure where safety, space, and energy efficiency are critical.

By using types of bus bar appropriately, designers can optimize systems for both cost and performance. The modularity, low maintenance, and high reliability make bus ducts a preferred choice over traditional wiring.

As smart building technologies continue to evolve, the role of bus bar electrical systems will become even more prominent. Combined with advancements like Energy Management System in Smart Grid, bus ducts will remain central to modern electrical engineering design.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights to get the latest updates in Electrical Engineering.

#BusDuct, #ElectricalSystem, #PowerDistribution, #ElectricalEngineering, #BusDuctDesign, #IndustrialElectrical, #BusDuctInstallation, #ElectricalSafety, #EnergyDistribution, #BuswaySystem, #ElectricPower, #ElectricalPanel, #ElectricalComponents, #HVACSystems, #SubstationDesign