IEC Standard for Instrument Calibration: Complete Compliance Guide for Accurate Measurements

The IEC standard for instrument calibration plays a critical role in ensuring accuracy, safety, and consistency in electrical and industrial measurements across the world. In power plants, manufacturing units, laboratories, and automation systems, calibrated instruments form the backbone of reliable operations. Without a globally accepted framework, measurement errors could lead to equipment failure, safety hazards, and costly downtime.

Table of Contents

This article explains the IEC standard for instrument calibration in a practical, engineering-focused manner. It covers applicable IEC standards, calibration requirements, procedures, documentation, and industry best practices while keeping the discussion easy to read and technically sound.

Understanding Instrument Calibration in Engineering

Instrument calibration is the process of comparing a measuring instrument with a reference standard to determine and correct deviations. The objective is to ensure that instruments deliver measurements within acceptable accuracy limits.

Learn more about earthing cable size as per iec

In industrial environments, calibration applies to:

- Electrical measuring instruments

- Process control sensors

- Protection relays

- Test and measurement equipment

- Laboratory instruments

The IEC standard for instrument calibration ensures that these activities follow internationally recognized rules, making measurements consistent across borders and industries.

Role of IEC in Calibration Standards

The International Electrotechnical Commission (IEC) develops international standards for electrical, electronic, and related technologies. Unlike general quality standards, IEC documents focus specifically on technical performance, safety, and measurement reliability.

The IEC standard for instrument calibration does not exist as a single document. Instead, it is defined through multiple IEC standards that collectively guide calibration practices, reference accuracy, traceability, and documentation.

Know more about IEC Standard for Insulation Resistance Test – Procedures, Limits & Best Practices Explained

Key IEC Standards Related to Instrument Calibration

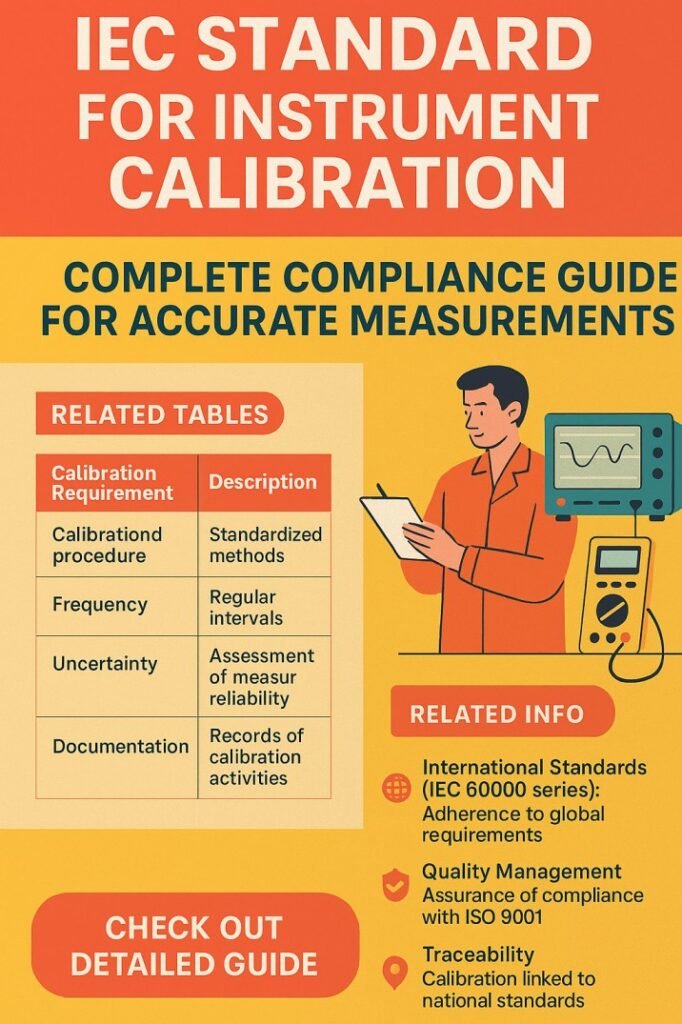

Several IEC standards directly or indirectly define calibration requirements. The table below summarizes the most relevant ones.

| IEC Standard | Scope | Relevance to Calibration |

|---|---|---|

| IEC 60051 | Direct acting indicating instruments | Accuracy classes and performance limits |

| IEC 61010 | Safety requirements for measurement equipment | Safe calibration practices |

| IEC 61557 | Electrical safety test instruments | Calibration of insulation and earth testers |

| IEC 61850 | Communication networks in substations | Validation and testing of measurement data |

| IEC 61326 | EMC requirements | Ensures stable measurement during calibration |

| IEC 60477 | Laboratory DC power supplies | Reference sources for calibration |

These documents collectively shape the IEC standard for instrument calibration used in industrial and laboratory environments.

Find out more about iec 61439 busbar clearance

Calibration Accuracy and Tolerance Classes

Accuracy classes are fundamental in IEC-based calibration. Instruments are classified based on maximum permissible error expressed as a percentage of full-scale value.

Common accuracy classes include:

- Class 0.1

- Class 0.2

- Class 0.5

- Class 1.0

During calibration, the measured deviation must remain within the defined class limits. The IEC standard for instrument calibration ensures that these classes are clearly defined and uniformly applied.

Traceability Requirements Under IEC Framework

Traceability is the ability to relate measurement results to international or national standards through an unbroken chain of comparisons.

Understand better about nec 430.32

According to the IEC standard for instrument calibration, traceability must:

- Link reference instruments to national metrology institutes

- Use certified calibration standards

- Maintain documented calibration chains

- Include uncertainty calculations

This approach ensures that measurements taken in different countries or facilities remain comparable and trustworthy.

Calibration Intervals and Frequency

IEC standards do not mandate fixed calibration intervals. Instead, they provide guidance based on risk, usage, and environmental conditions.

Know more about IEC Standard for MV Cable Testing: Complete Acceptance, Routine & Type Test Guide

Typical factors influencing calibration frequency include:

- Instrument criticality

- Measurement drift history

- Operating environment

- Manufacturer recommendations

- Regulatory requirements

In practice, the IEC standard for instrument calibration encourages a risk-based calibration interval rather than arbitrary schedules.

Calibration Procedures as per IEC Guidelines

A standard IEC-compliant calibration procedure usually follows these steps:

- Visual inspection of the instrument

- Verification of environmental conditions

- Comparison with reference standard

- Measurement at multiple test points

- Recording deviations and uncertainty

- Adjustment if permitted

- Issuance of calibration report

These steps help ensure repeatability and consistency, which is central to the IEC standard for instrument calibration philosophy.

Environmental Conditions During Calibration

Calibration accuracy is highly sensitive to environmental factors. IEC standards emphasize controlled conditions to minimize measurement uncertainty.

Know more about Electrical Standards USA – National Electrical Code | Electrical Safety Foundation

Recommended conditions include:

- Stable ambient temperature

- Controlled humidity levels

- Minimal electromagnetic interference

- Proper grounding and shielding

By standardizing test environments, the IEC standard for instrument calibration reduces variability caused by external factors.

Documentation and Calibration Certificates

Proper documentation is as important as the calibration itself. IEC-based calibration certificates must contain specific information.

Use our online tool electricity load calculator in kw for home

| Certificate Element | Description |

|---|---|

| Instrument identification | Model, serial number, range |

| Reference standards | Traceable standard details |

| Calibration date | Date of performance |

| Measurement results | Actual vs reference values |

| Uncertainty | Calculated measurement uncertainty |

| Compliance statement | Conformance to IEC criteria |

Accurate documentation strengthens audit readiness and compliance with the IEC standard for instrument calibration.

IEC vs ISO Calibration Requirements

IEC and ISO standards often work together. While ISO 9001 and ISO/IEC 17025 define quality system and laboratory competence, IEC standards focus on technical measurement aspects.

Key differences include:

- IEC defines instrument-specific performance limits

- ISO defines management and quality systems

- IEC emphasizes electrical safety and accuracy

- ISO emphasizes process consistency

Together, they complement the IEC standard for instrument calibration framework used in professional environments.

Use our online tool Creepage Distance Calculator – Calculate Safe Insulation & Clearance for PCB and High Voltage Design

Application in Power and Industrial Systems

In power generation and industrial automation, calibrated instruments ensure:

- Accurate energy measurement

- Reliable protection relay operation

- Stable process control loops

- Compliance with grid codes

The IEC standard for instrument calibration is widely used in substations, control rooms, testing labs, and manufacturing plants.

Common Challenges in IEC-Based Calibration

Despite clear guidelines, organizations face practical challenges:

- Lack of trained calibration personnel

- Poor traceability of reference standards

- Incomplete documentation

- Environmental control issues

Addressing these challenges requires structured calibration programs aligned with the IEC standard for instrument calibration.

Know more about 7 Common Mistakes in Electrical Outlet Height

Best Practices for Compliance

To effectively implement IEC-based calibration, organizations should:

- Maintain a centralized calibration register

- Use accredited calibration laboratories

- Train technical staff regularly

- Review calibration data trends

- Integrate calibration with asset management systems

These practices improve measurement reliability and long-term compliance with the IEC standard for instrument calibration.

Future Trends in Instrument Calibration

With the rise of smart instruments and digital substations, calibration is evolving. Remote calibration verification, self-diagnostics, and digital traceability are becoming common.

IEC continues to update standards to address:

- Digital measurement accuracy

- Cybersecurity of calibration data

- Interoperability of smart sensors

These advancements will further strengthen the IEC standard for instrument calibration in modern engineering systems.

Know more about IEC Standard for Earthing System

Conclusion

The IEC standard for instrument calibration provides a structured, internationally accepted framework for maintaining measurement accuracy, safety, and reliability. By following IEC guidelines, industries can ensure traceable measurements, regulatory compliance, and consistent performance across electrical and industrial systems.

For engineers, technicians, and quality professionals, understanding and applying the IEC standard for instrument calibration is not just a compliance requirement but a foundation for operational excellence and technical credibility.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#IECStandardForInstrumentCalibration, #InstrumentCalibration, #IECStandards, #CalibrationStandards, #IndustrialCalibration, #MeasurementAccuracy, #ElectricalInstrumentation, #QualityCompliance, #CalibrationProcess, #TestAndMeasurement