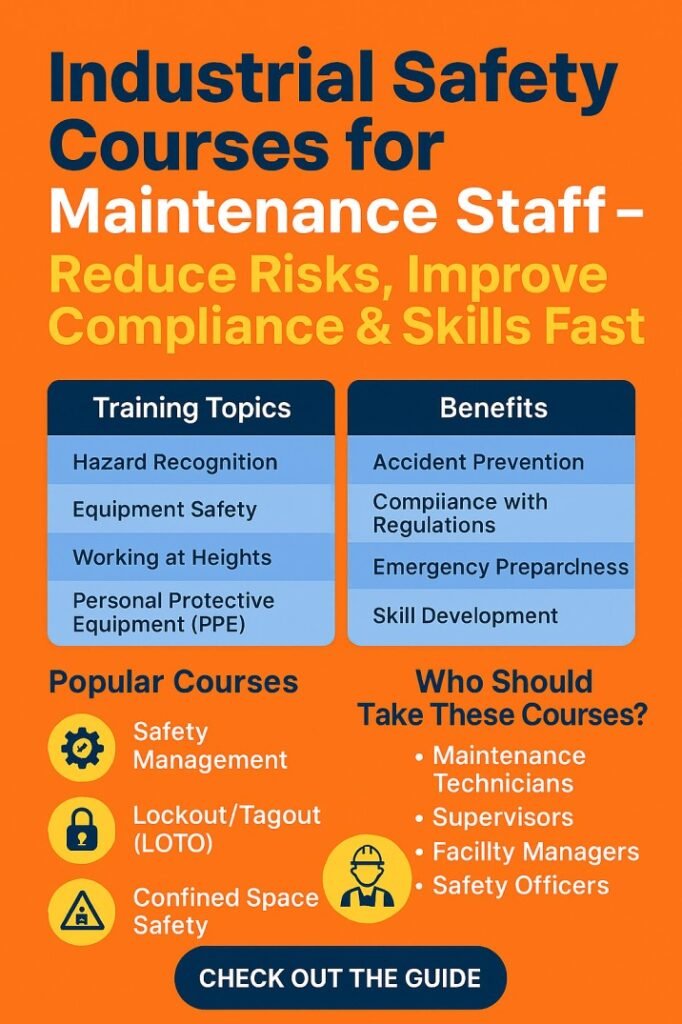

Industrial Safety Courses for Maintenance Staff – Reduce Risks, Improve Compliance & Skills Fast

Industrial safety courses for maintenance staff play a critical role in protecting workers, assets, and production continuity in modern industries. Maintenance teams work close to live equipment, electrical systems, rotating machinery, confined spaces, and hazardous chemicals. One small mistake can lead to serious injury, unplanned shutdowns, or regulatory penalties. That is why structured safety training is no longer optional; it is a core operational requirement.

Table of Contents

Industrial safety courses for maintenance staff are designed to reduce workplace risks, improve legal compliance, and upgrade technical safety skills in a short time. These programs focus on real hazards faced by technicians, electricians, mechanical fitters, and instrumentation staff. When implemented correctly, they create a strong safety culture while improving maintenance efficiency and confidence on the job.

Learn more about Top 15 Best Electrical Courses in UK: Industrial Trainings Which Pay More

Why Maintenance Staff Face Higher Safety Risks

Maintenance work is inherently more dangerous than routine operations. Staff often deal with unexpected faults, emergency repairs, and non standard conditions. Equipment may be energized, partially isolated, or mechanically unstable during maintenance activities. Without proper training, even experienced technicians can underestimate risks.

Industrial safety courses for maintenance staff address these challenges by focusing on task based hazards rather than generic safety rules. Training connects safety procedures with daily maintenance activities, making learning practical and easy to apply.

Common risk factors include:

- Working on live electrical panels

- Lockout and tagout failures

- Exposure to moving machinery

- Hot work such as welding and cutting

- Confined space entry

- Working at heights

- Chemical handling and spills

By targeting these risks, industrial safety courses for maintenance staff help reduce accident rates and near misses significantly.

Know more about DEWA Electrical License Guide for Solar Projects in Dubai

Core Objectives of Industrial Safety Training

The main goal of industrial safety courses for maintenance staff is not just compliance, but behavior change. Effective training builds awareness, discipline, and responsibility.

Key objectives include:

- Identifying hazards before starting work

- Applying safe work procedures consistently

- Understanding legal and company safety requirements

- Responding correctly to emergencies

- Protecting co workers and equipment

- Reducing downtime caused by accidents

When maintenance teams understand why a rule exists, not just what the rule is, compliance improves naturally.

Essential Topics Covered in Safety Courses

High quality industrial safety courses for maintenance staff cover a wide range of technical and behavioral topics. The focus remains on practical situations rather than theory.

Typical modules include:

- Electrical safety and arc flash awareness

- Lockout tagout procedures

- Mechanical safety and machine guarding

- Permit to work systems

- Confined space safety

- Working at height safety

- Fire prevention and firefighting

- Personal protective equipment selection

- Hazard identification and risk assessment

- Emergency response and first aid basics

These topics ensure maintenance personnel can safely handle both routine and emergency tasks.

Know more about Electrical Safety Officer Roles & Responsibilities

Table: Common Maintenance Hazards and Training Focus

| Maintenance Hazard | Risk Level | Training Focus Area |

|---|---|---|

| Live electrical work | High | Electrical isolation, PPE, arc flash safety |

| Rotating machinery | High | Machine guarding, safe shutdown |

| Confined spaces | Very High | Gas testing, entry permits |

| Hot work | Medium | Fire watch, hot work permits |

| Working at heights | High | Fall protection systems |

| Chemical exposure | Medium | MSDS awareness, spill control |

This table shows how industrial safety courses for maintenance staff directly map training content to real world risks.

Compliance and Legal Importance

Regulatory authorities expect organizations to train their maintenance staff properly. Safety laws often require documented training records, competency assessments, and refresher courses.

Industrial safety courses for maintenance staff help organizations comply with:

- Occupational health and safety regulations

- Electrical safety standards

- Fire safety codes

- Environmental protection rules

- Insurance and audit requirements

Know more about Electrical Safety Officer Certification in USA: Cost, Duration & Job Scope

Non compliance can result in fines, legal action, increased insurance premiums, and reputational damage. Training is a cost effective way to avoid these consequences.

Skill Improvement Beyond Safety

One major advantage of industrial safety courses for maintenance staff is skill enhancement. Safety training often improves technical understanding of equipment and systems.

Benefits include:

- Better fault diagnosis with reduced risk

- Improved use of tools and instruments

- Increased confidence during complex repairs

- Stronger teamwork and communication

- Higher job satisfaction and morale

When staff feel competent and safe, productivity naturally improves.

Fast Skill Development Through Targeted Training

Modern industrial safety courses for maintenance staff are designed for fast learning without disrupting operations. Many programs use modular formats that can be completed in short sessions.

Know more about Journeyman Electrician Practice Test: Important Question to Prepare

Common delivery methods:

- On site classroom training

- Practical demonstrations in plant areas

- Toolbox talks and micro learning

- Online theory with practical assessments

- Simulation based training

This approach allows maintenance teams to apply what they learn immediately, reinforcing safe habits quickly.

Table: Training Duration vs Skill Impact

| Course Duration | Skill Impact | Best Use Case |

|---|---|---|

| Half day | Awareness level | New hires, refreshers |

| 1 to 2 days | Practical skills | Routine maintenance staff |

| 3 to 5 days | Advanced competency | Supervisors, lead technicians |

| Annual refresh | Behavior reinforcement | Compliance and audits |

Industrial safety courses for maintenance staff can be tailored to match both risk level and operational needs.

Know more about OSHA Certification Cost: 7 Proven Ways to Save Big on Your Training

Selecting the Right Safety Course Provider

Not all training programs deliver the same results. Choosing the right provider is essential for long term impact.

Look for:

- Industry specific experience

- Qualified instructors with field background

- Practical case studies and demonstrations

- Recognized certifications

- Customization based on plant hazards

- Post training assessments

Industrial safety courses for maintenance staff should reflect actual equipment, processes, and risks found on site.

Measuring Training Effectiveness

Training is only effective if it leads to measurable improvement. Organizations should track performance indicators after training.

Know more about Top 50 NICET Practice Exams Questions and Answers

Key indicators include:

- Reduction in accidents and near misses

- Improved safety audit scores

- Better compliance during inspections

- Increased reporting of unsafe conditions

- Lower equipment damage incidents

Regular evaluation ensures that industrial safety courses for maintenance staff continue to deliver value.

Long Term Benefits for Organizations

Investing in industrial safety courses for maintenance staff delivers long term operational and financial benefits.

Major advantages include:

- Reduced injury related costs

- Lower downtime and maintenance errors

- Stronger safety culture

- Improved employee retention

- Better reputation with clients and regulators

Safety trained maintenance staff become an asset rather than a risk.

Know in detail Top 15 Electrician Apprenticeship Programs in USA That Lead to High-Paying Careers

Final Thoughts

Industrial safety courses for maintenance staff are one of the most effective tools to reduce workplace risks while improving compliance and technical skills quickly. Maintenance teams operate at the frontline of industrial hazards, and proper training equips them to handle challenges safely and confidently.

Organizations that prioritize structured safety training see fewer accidents, higher productivity, and stronger operational control. In today’s competitive industrial environment, investing in industrial safety courses for maintenance staff is not just about meeting regulations; it is about protecting people, processes, and performance in the long run.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#IndustrialSafetyCourses, #MaintenanceStaffTraining, #WorkplaceSafetyTraining, #IndustrialMaintenanceSafety, #OSHAAlignedTraining, #PlantSafetyCourses, #TechnicalSafetySkills, #MaintenanceSafetyPrograms, #IndustrialWorkplaceSafety, #SafetyTrainingForTechnicians