Lockout Tagout Procedures: The Complete Guide to Workplace Safety & Compliance

Workplace safety is a critical aspect of industrial operations, and one of the most effective ways to protect employees from hazardous energy is through proper lockout tagout procedures. These procedures are essential for preventing accidental machine start-ups and energy releases during maintenance, repair, or inspection activities. A well-implemented lockout tagout program not only ensures compliance with safety regulations but also significantly reduces the risk of workplace injuries and fatalities.

Table of Contents

Lockout tagout procedures, often abbreviated as LOTO, are a cornerstone of occupational safety programs. They involve isolating and controlling hazardous energy sources before servicing equipment. Understanding and applying these procedures correctly is vital for every safety-conscious organization.

Know more about DEWA Electrical License Guide for Solar Projects in Dubai

What Are Lockout Tagout Procedures?

Lockout tagout procedures are systematic steps designed to control hazardous energy in machinery and equipment. These procedures include shutting down equipment, isolating energy sources, applying locks and tags, and verifying that the energy has been effectively controlled.

The primary goal of these procedures is to prevent unexpected energization, release of stored energy, or startup of machinery that could lead to serious injuries such as electrocution, crushing, or amputations. They are especially critical in manufacturing, industrial, and maintenance environments where employees interact with heavy machinery and electrical systems.

Importance of Lockout Tagout Procedures

Implementing lockout tagout procedures is crucial for several reasons:

- Worker Safety: Proper LOTO procedures reduce the risk of accidents caused by uncontrolled energy releases.

- Regulatory Compliance: OSHA and other safety organizations require strict adherence to lockout tagout standards.

- Equipment Protection: Preventing accidental startup protects machinery from damage during maintenance.

- Operational Efficiency: Well-structured LOTO procedures streamline maintenance tasks and reduce downtime.

Know more about Electrical Safety Officer Roles & Responsibilities

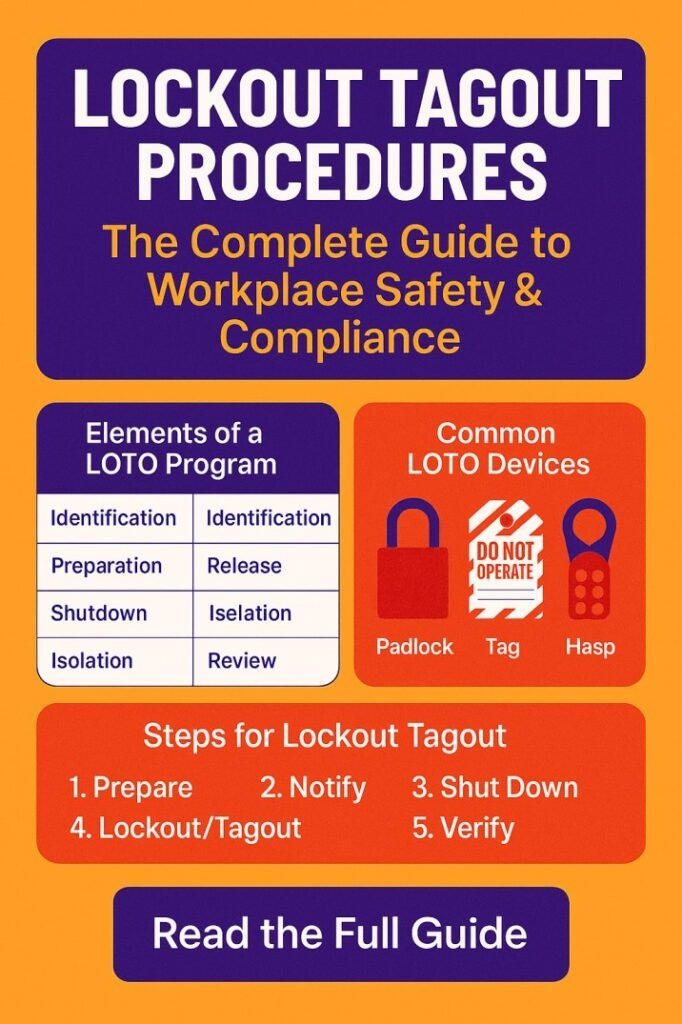

Key Components of Lockout Tagout Procedures

Effective lockout tagout procedures consist of several key components:

- Energy Control Measures: Identify all energy sources such as electrical, mechanical, hydraulic, pneumatic, chemical, and thermal.

- Lockout Devices: Physical locks used to isolate energy sources.

- Tagout Devices: Tags providing information about the energy isolation and warning against energization.

- Authorized Personnel: Only trained and authorized employees should implement LOTO procedures.

- Verification Steps: Confirm that energy sources have been isolated and the equipment is safe to service.

Step-by-Step Lockout Tagout Procedures

Following a structured approach ensures the effectiveness of lockout tagout procedures. The following steps are commonly recommended:

- Prepare for Shutdown

- Notify affected employees about the upcoming maintenance.

- Identify all energy sources and determine the method of control.

- Shut Down Equipment

- Follow standard operating procedures to safely turn off machinery.

- Isolate Energy Sources

- Disconnect power, block mechanical movement, or release stored energy.

- Apply Lockout/Tagout Devices

- Attach locks and tags to energy isolation points.

- Ensure each device is secure and easily visible.

- Release Residual Energy

- Drain stored energy from springs, capacitors, or hydraulic systems.

- Verify Isolation

- Attempt to start the equipment to ensure it cannot be energized.

- Confirm with a checklist if needed.

- Perform Maintenance

- Proceed with maintenance, repair, or inspection only after verification.

- Remove Lockout/Tagout Devices

- Authorized personnel must remove devices after work completion.

- Notify affected employees before restoring energy.

Know more about Electrical Safety Officer Certification in USA: Cost, Duration & Job Scope

Types of Hazardous Energy Controlled in LOTO

Understanding the types of energy that require lockout tagout procedures helps in preventing accidents effectively.

| Type of Energy | Examples | Control Measures |

|---|---|---|

| Electrical Energy | Motors, circuits, electrical panels | Disconnect power, apply electrical locks |

| Mechanical Energy | Gears, springs, conveyors | Use mechanical blocks, release stored tension |

| Hydraulic Energy | Presses, lifts, hydraulic lines | Close valves, release pressure, install lock valves |

| Pneumatic Energy | Air compressors, pneumatic tools | Depressurize lines, lock valves |

| Thermal Energy | Steam, hot surfaces | Allow cooling, isolate heat sources |

| Chemical Energy | Reactants, pressurized chemicals | Contain chemicals, isolate tanks |

Training and Responsibilities

For lockout tagout procedures to be effective, employee training and clear responsibilities are essential.

- Authorized Employees: Trained to implement and remove lockout/tagout devices.

- Affected Employees: Workers who operate equipment must understand the procedures and avoid bypassing LOTO devices.

- Inspectors and Supervisors: Ensure compliance, conduct periodic audits, and provide refresher training.

Regular training ensures employees recognize hazardous energy, understand proper LOTO techniques, and comply with safety standards. OSHA recommends that employers conduct both initial and annual training sessions.

Know more about Journeyman Electrician Practice Test: Important Question to Prepare

Common Mistakes in Lockout Tagout Procedures

Even with structured procedures, common mistakes can compromise safety. Organizations should avoid:

- Skipping the verification step before maintenance.

- Using unauthorized or improvised lockout devices.

- Failing to notify affected employees.

- Overlooking energy sources during the shutdown.

- Ignoring periodic audits and inspections.

By addressing these mistakes, companies can maintain a safer work environment and remain compliant with safety regulations.

Benefits of Implementing Lockout Tagout Procedures

Investing in proper LOTO procedures provides several tangible and intangible benefits:

- Reduced Workplace Accidents: Significantly lowers injury rates related to machinery.

- Compliance with OSHA Standards: Avoids penalties and legal liabilities.

- Enhanced Productivity: Minimizes downtime due to accidents or improper shutdowns.

- Improved Employee Confidence: Workers feel secure, leading to higher engagement and morale.

Know more about OSHA Certification Cost: 7 Proven Ways to Save Big on Your Training

OSHA Requirements and Compliance

The Occupational Safety and Health Administration (OSHA) outlines specific requirements for lockout tagout procedures under 29 CFR 1910.147. Key points include:

- Energy control programs must be documented in writing.

- Employees must receive proper training on LOTO procedures.

- Periodic inspections of lockout/tagout devices are mandatory.

- Only authorized employees can apply or remove LOTO devices.

Compliance with these standards not only protects employees but also safeguards the company from regulatory action and potential litigation.

Best Practices for Effective Lockout Tagout Procedures

To ensure maximum safety and efficiency, organizations should follow best practices:

- Maintain an updated energy control procedure for each machine.

- Use standardized lockout/tagout devices for consistency.

- Conduct periodic audits to identify gaps in the LOTO program.

- Encourage employee feedback and report near-misses.

- Integrate LOTO procedures with overall safety management systems.

Know more about Top 50 NICET Practice Exams Questions and Answers

Conclusion

Lockout tagout procedures are not just a regulatory requirement—they are a critical aspect of workplace safety. By systematically isolating hazardous energy, applying locks and tags, and ensuring employee training, organizations can prevent serious accidents, maintain compliance, and promote a safety-first culture.

A robust lockout tagout program requires commitment, proper training, and consistent enforcement. Organizations that prioritize LOTO procedures will not only protect their workforce but also enhance productivity, reduce downtime, and achieve long-term operational excellence. Adopting these procedures ensures a safer work environment, mitigates risks, and fulfills the essential responsibility of every employer to safeguard human life.

Know in detail Top 15 Electrician Apprenticeship Programs in USA That Lead to High-Paying Careers

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#LockoutTagoutProcedures, #LOTO, #WorkplaceSafety, #IndustrialSafety, #OSHACompliance, #MachineSafety, #EnergyControl, #SafetyTraining, #AccidentPrevention, #SafetyProcedures