How to Improve Power Factor in Factories and Commercial Buildings: Best Guide

Improving power factor has become a critical priority for facility managers, plant engineers, and commercial building owners. A low power factor increases electricity bills, stresses electrical equipment, and reduces the effective capacity of the power distribution system. When utilities charge penalties for poor power factor, the financial impact becomes even more significant. Understanding how to improve power factor and applying practical solutions can lead to measurable cost savings and improved operational reliability.

Table of Contents

Power factor measures how effectively a facility uses electrical power. When the power factor is low, the system draws more current than necessary. This creates losses, overheating, voltage drops, and reduced system efficiency. Fortunately, factories and commercial buildings can apply multiple methods to correct and maintain good power factor.

This article explains how to improve power factor using proven techniques, simplified explanations, and easy-to-follow steps.

What Is Power Factor and Why It Matters

Power factor is the ratio between real power (kW) and apparent power (kVA). Real power does useful work. Apparent power is the total power supplied. When the ratio is low, it means the electrical system is not working efficiently.

Most industrial and commercial loads, such as motors, HVAC systems, compressors, pumps, and fluorescent lighting, are inductive. Inductive loads draw reactive power (kVAR), and this reduces the overall power factor.

Know more about Load Factor Calculation in Electricity Bill

A low power factor results in:

- Higher electricity bills

- Penalties from the utility company

- Overloaded transformers and switchgear

- Conductor heating and energy losses

- Reduced voltage and poor equipment performance

For these reasons, improving power factor is essential for efficient and stable operations.

Know more about how to measure power factor with multimeter

Power Factor Improvement Calculator

Power Factor Improvement Calculator

Calculate required capacitor kVAR to improve power factor from initial to target value.

– Enter load in kW, initial power factor, target power factor, system voltage, and frequency.

– Click “Calculate” to see required capacitor kVAR, initial reactive power, final reactive power, and capacitor current.

– Formula used: Required kVAR = kW × (tan(cos⁻¹(pf₁)) − tan(cos⁻¹(pf₂))).

– Capacitor current = (kVAR × 1000) ÷ (√3 × V).

– This calculator assumes balanced three‑phase load and sinusoidal conditions.

Formula check: – Initial reactive power Q₁ = kW × tan(cos⁻¹(pf₁)). – Final reactive power Q₂ = kW × tan(cos⁻¹(pf₂)). – Required capacitor kVAR = Q₁ − Q₂. – Capacitor current I_c = (kVAR × 1000) ÷ (√3 × V). Verified against standard PF correction equations.

Common Causes of Low Power Factor

Factories and commercial buildings often face poor power factor due to:

- Excessive inductive loads

- Oversized motors

- Unloaded or lightly loaded motors

- Long cable lengths

- Harmonics from VFDs or electronic devices

- Old lighting systems

- Transformers operating at low load

When you identify the cause, the improvement strategy becomes easier to apply.

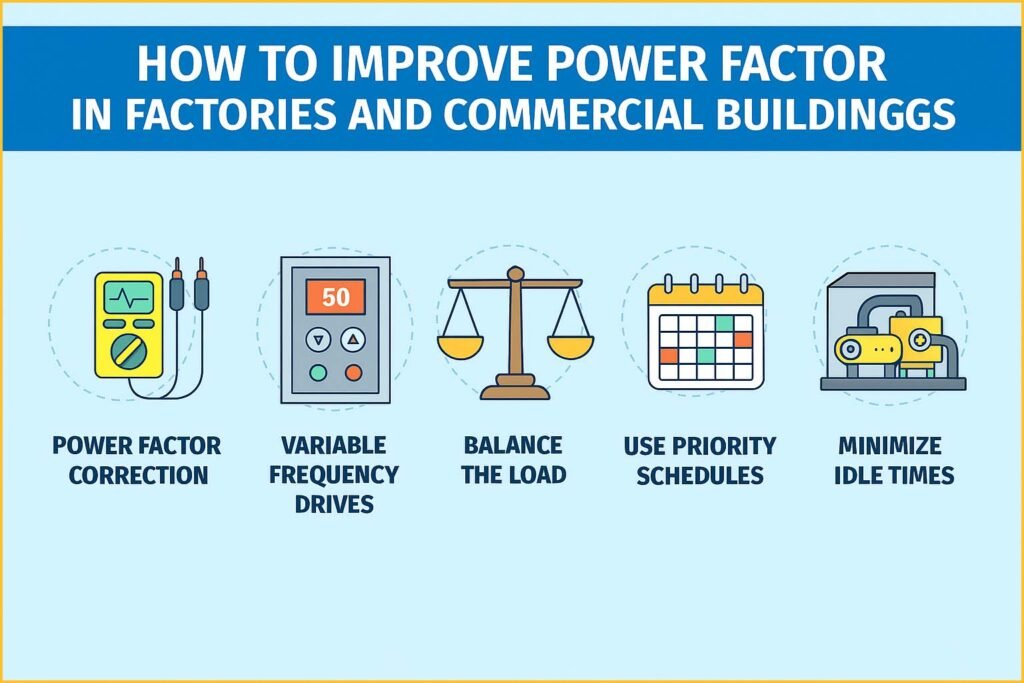

Methods on How to Improve Power Factor

Multiple solutions exist for improving power factor. Most facilities use a combination of them to reach target levels such as 0.95 or higher.

Know more about how to calculate power factor from electricity bill

Install Power Factor Correction Capacitors

This is the most widely used and effective method. Capacitors supply leading reactive power, which cancels out lagging reactive power from inductive loads.

Types of Capacitor Solutions

| Capacitor Type | Application | Advantages |

|---|---|---|

| Fixed Capacitors | Constant loads | Simple and low cost |

| Automatic Capacitor Banks | Fluctuating loads | Maintains constant power factor |

| Detuned Capacitors | Loads with VFDs or harmonics | Prevents capacitor damage |

| Individual Capacitors | Motors and compressors | Corrects at equipment level |

Capacitor banks automatically switch stages ON and OFF based on the load requirement. This provides stable power factor throughout the day.

Know more about Automatic Power Factor Correction Using Arduino

Improve Motor Efficiency and Loading

Motors are among the largest contributors to poor power factor in industrial environments. When motors run below 60 percent load, they draw more reactive power.

Steps to improve motor efficiency

- Replace oversized motors with right-sized motors

- Use high-efficiency motors

- Remove redundant or idle motors

- Ensure preventive maintenance for motors

- Use VFDs properly for variable load applications

Correct motor sizing improves both power factor and energy efficiency.

Know more about Capacity Factor vs Load Factor – Key Differences, Formula, and Examples Explained

Replace Old Lighting with LED Technology

Older lighting systems such as fluorescent lamps, mercury lamps, and metal halide fixtures lower the power factor. These lighting systems use ballasts that draw reactive power.

LED lighting offers:

- Better power factor, often above 0.95

- Significant reduction in energy consumption

- Lower heat production

- Longer lifespan and less maintenance

Lighting upgrades provide long-term savings and immediate improvements to power factor.

Know more about kwh kvah power factor

Use Synchronous Condensers

Large industrial plants sometimes use synchronous condensers. These machines operate like unloaded synchronous motors that generate reactive power.

Advantages include:

- Adjustable reactive power

- High reliability

- Ability to stabilize voltage

- Suitable for heavy industrial loads

They are more expensive than capacitor banks but ideal for plants with large and dynamic load variations.

Install Harmonic Filters

Harmonics produced by VFDs, UPS systems, inverters, and other electronic equipment distort current waveform. Harmonics reduce capacitor performance and lower overall power factor.

Harmonic filters help by:

- Reducing harmonic distortion

- Protecting capacitor banks

- Improving power system reliability

They are often used with automatic capacitor banks in industrial facilities.

Know more about demand factor vs power factor

Improve Load Scheduling

Facilities with fluctuating loads can improve power factor by planning when equipment runs.

Recommendations for load management

- Avoid running many inductive loads at the same time

- Start motors in sequence, not simultaneously

- Use soft starters to reduce inrush current

- Operate heavy machinery during peak efficiency hours

Load scheduling is a no-cost method and is effective when applied consistently.

Use our online tool Generator Size Calculator for Homes in KVA: Best Tool

Optimize Transformers and Distribution Systems

Transformers running at low load cause low power factor. They draw magnetizing current even when lightly loaded.

Improvement techniques

- Consolidate load to fewer transformers

- Shut down lightly loaded transformers

- Use energy-efficient transformers

- Shorten cable routes where possible to reduce reactive losses

This approach works best during facility upgrades or expansions.

Know more about power factor correction system

Install Automatic Power Factor Controllers

Automatic power factor controllers (APFC panels) monitor power factor in real time. They then switch capacitor stages to maintain a stable target value.

Benefits include:

- Accurate and fast correction

- No manual intervention

- Protection against over-correction

- Improved billing accuracy

APFC panels are essential for facilities with frequent load changes.

Conduct Regular Power Quality Audits

A power quality audit gives a clear picture of the electrical system. It identifies causes of poor power factor and recommends solutions.

An audit typically includes:

- Power factor analysis

- Harmonic measurement

- Load profiling

- Transformer analysis

- Cable loss estimation

Regular audits help prevent penalties and ensure continuous compliance.

Know more about Power Factor Correction Capacitor Calculator – Complete Technical Guide

Financial Benefits of Improving Power Factor

Correcting power factor delivers measurable financial advantages.

Estimated savings

| Scenario | Power Factor Before | Power Factor After | Benefit |

|---|---|---|---|

| Medium factory | 0.70 | 0.95 | Lower utility penalties |

| Commercial plaza | 0.75 | 0.98 | Reduced demand charges |

| Industrial plant | 0.68 | 0.96 | Increased transformer capacity |

When power factor increases, the current flow decreases. This reduces I²R losses and increases the lifespan of electrical equipment.

Practical Example

A manufacturing plant with a 400 kVA load and a power factor of 0.72 faced regular utility penalties. After installing an automatic capacitor bank, the power factor improved to 0.96. The plant reduced its monthly electricity bill significantly and avoided penalties. Additional benefits included stable voltage and reduced equipment overheating.

This example shows that improvements not only reduce costs but also enhance system performance.

Best Practices for Sustained High Power Factor

To maintain high power factor in the long term:

- Monitor power factor monthly

- Maintain capacitor banks and replace faulty stages

- Check harmonic levels yearly

- Update load schedules when equipment changes

- Train staff on energy-efficient practices

- Perform preventive maintenance on motors and transformers

A continuous improvement approach ensures that the facility always operates at optimal efficiency.

Know more about Energy Audit for Commercial Buildings: Step-by-Step Guide

Conclusion

Understanding how to improve power factor is essential for factories and commercial buildings looking to reduce energy costs, avoid penalties, and enhance system reliability. The most effective methods include installing capacitor banks, optimizing motor loads, upgrading lighting, reducing harmonics, and using automatic power factor controllers. When these measures are applied correctly, facilities benefit from lower bills, better equipment performance, and improved operational stability.

Improving power factor is not a one-time effort. It requires monitoring, maintenance, and strategic upgrades. With the right approach, any facility can achieve a high power factor and enjoy consistent long-term savings.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#PowerFactor, #EnergyEfficiency, #IndustrialPower, #CommercialBuildings, #ElectricalSystems, #PowerQuality, #EnergyManagement, #ReactivePower, #DemandCharges, #ElectricalEngineering