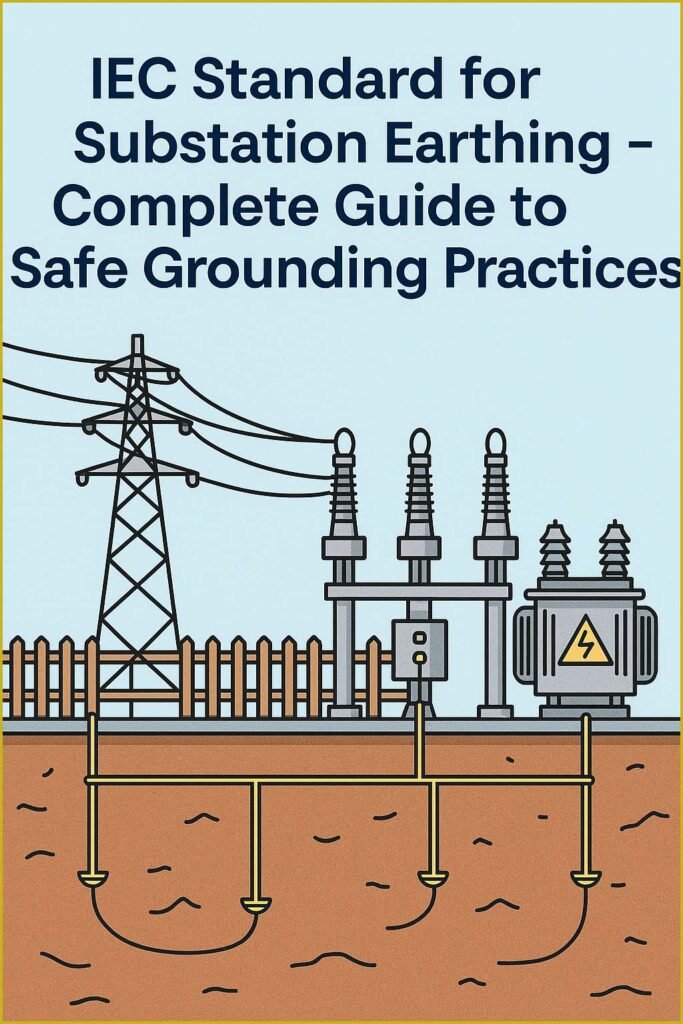

IEC Standard for Substation Earthing – Complete Guide to Safe Grounding Practices

Substation earthing is a critical aspect of electrical power systems. Proper earthing ensures the safety of personnel, protects equipment, and maintains system reliability. The IEC standard for substation earthing provides clear guidelines for designing, implementing, and maintaining grounding systems in substations. This article delves deep into these standards, explaining the principles, design criteria, and practical implementation steps.

Table of Contents

Importance of IEC Standard for Substation Earthing

Earthing in substations serves multiple purposes. First, it protects human life by providing a low-resistance path for fault currents. Second, it safeguards equipment from voltage surges caused by lightning or switching operations. Third, it ensures system stability by maintaining the neutral point at ground potential. The IEC standard for substation earthing defines minimum requirements for these protective measures, ensuring a safe and efficient electrical system.

Failure to follow the IEC standard can lead to hazardous conditions, such as electric shock, equipment damage, and system instability. Therefore, understanding and applying these standards is essential for engineers and designers working in the electrical power sector.

Know more about IEC Standards for Transformer Testing – Complete Guide to IEC 60076 and Testing Procedures

Principles of Substation Earthing

The IEC standard for substation earthing is based on several key principles. The first principle is the reduction of touch and step voltage to safe levels. Touch voltage is the voltage a person experiences when touching an earthed object, while step voltage is the voltage between the feet of a person standing near a fault. The earthing system must limit these voltages to prevent injuries.

Another principle is the distribution of fault currents over a large area. This helps to minimize local voltage rises and reduces the risk of equipment damage. The earthing system should have low impedance to allow rapid dissipation of fault currents. Reliability is also a major focus. The IEC standard emphasizes durable materials, corrosion resistance, and regular maintenance to ensure the earthing system functions correctly over the lifetime of the substation.

Know more about Methods of Electrical Earthing: Important Concepts

Types of Earthing Systems in Substations

Substation earthing can be classified into several types. The IEC standard for substation earthing highlights the importance of selecting the right type based on substation design, soil resistivity, and fault current levels. The common types include:

Grid Earthing System: A network of interconnected conductors forming a grid beneath the substation. This system offers low impedance and distributes fault currents evenly.

Rod or Pipe Earthing: Vertical rods or pipes driven into the ground. These are often used in areas with high soil resistivity or where a grid is impractical.

Strip Earthing: Conductive strips buried in trenches, usually connected to the main grid or rods. This method is often used in combination with other systems to improve performance.

Plate Earthing: Metal plates buried in moist soil, providing a large contact area to reduce earth resistance.

Each earthing type has advantages and limitations. The IEC standard recommends grid earthing as the most reliable solution for high-voltage substations due to its ability to handle large fault currents and maintain low touch and step voltages.

Know more about IEC Standard for XLPE Cables – Complete Guide to IEC 60502 and Electrical Cable Specifications

Design Considerations According to IEC Standard

Designing an earthing system requires careful consideration of several factors. The IEC standard for substation earthing specifies the design criteria to ensure safety and functionality. Key design parameters include soil resistivity, fault current magnitude, substation voltage level, and environmental conditions.

Soil resistivity is one of the most critical factors. It affects the overall resistance of the grounding system. Engineers typically perform soil resistivity tests using the Wenner or Schlumberger method to determine appropriate conductor size and layout.

Fault current is another important consideration. The earthing system must safely carry maximum expected fault currents without excessive voltage rise. This ensures the safety of personnel and protects equipment.

Substation layout also affects earthing design. Equipment placement, conductor spacing, and grounding connections must minimize step and touch voltage risks. Environmental factors such as moisture content, temperature variations, and chemical soil composition are also considered to prevent corrosion and degradation of the earthing system.

Materials Used in Substation Earthing

The IEC standard for substation earthing recommends materials that are highly conductive, durable, and resistant to corrosion. Copper is the most common conductor due to its excellent conductivity and long-term reliability. Copper-clad steel and galvanized steel are also used in some applications for cost efficiency and mechanical strength.

Connections and joints must ensure low resistance and mechanical stability. The IEC standard emphasizes the use of corrosion-resistant clamps, welds, and exothermic bonding techniques. Regular inspection and maintenance are also recommended to ensure that connections remain reliable over time.

Know more about IEC Standard for Vibration Testing – IEC 60068 Explained with Procedures and Requirements

Step and Touch Voltage Calculations

Step and touch voltage calculations are essential for substation safety. The IEC standard provides methods to determine maximum allowable voltages. The formulas consider earth resistance, fault current, body impedance, and duration of fault.

| Parameter | Description | Typical Value |

|---|---|---|

| Touch Voltage | Voltage between hand and feet while touching earthed equipment | < 430 V (AC) |

| Step Voltage | Voltage difference between feet while standing near fault | < 208 V (AC) |

| Fault Duration | Time over which fault persists | 0.2–1 s |

The earthing grid design aims to keep step and touch voltages below these limits under maximum fault conditions. Proper layout, conductor sizing, and soil treatment help achieve this goal.

Earthing Grid Design

The earthing grid is the backbone of substation earthing. According to IEC standards, the grid should cover the entire substation area and extend under major equipment foundations. The conductors are arranged in a mesh pattern with horizontal and vertical connections to reduce resistance and distribute fault current evenly.

Typical grid spacing ranges from 3 to 10 meters, depending on voltage level, soil resistivity, and fault current. Conductors are usually copper strips or rods buried at a depth of 0.5 to 1.0 meters. Ground enhancement materials may be used in high-resistivity soils to improve performance.

Testing and Maintenance

IEC standard for substation earthing emphasizes routine testing and maintenance to ensure system integrity. Common tests include earth resistance measurement, continuity checks, and soil resistivity evaluation. Earth resistance should generally be below 1 ohm for high-voltage substations, although acceptable values may vary based on site conditions.

Know more about IEC Standard for Relay Coordination – Complete Guide to Protection and Coordination Studies

Maintenance involves inspecting connections, replacing corroded conductors, and ensuring proper bonding between equipment and grid. This prevents deterioration over time and maintains compliance with IEC safety requirements.

Earthing for Lightning Protection

Substations are prone to lightning strikes, which can cause severe equipment damage. The IEC standard integrates lightning protection with earthing design. Lightning arresters are connected to the grid, providing a low-resistance path for surge currents.

The earthing system must be capable of dissipating high transient currents without causing dangerous step or touch voltages. This involves using larger conductors, bonding all metallic structures, and ensuring a continuous low-resistance path to ground.

Practical Implementation Tips

Implementing an earthing system according to IEC standards requires careful planning and execution. First, conduct a detailed site survey to assess soil conditions and identify potential hazards. Next, design the grid layout considering equipment positions, fault current levels, and step/touch voltage limits.

During installation, ensure proper depth and spacing of conductors. Use corrosion-resistant materials and verify all joints with proper bonding techniques. After installation, perform comprehensive testing to confirm compliance with IEC standards. Regular maintenance and periodic inspections are essential for long-term reliability.

Know more about IEC Standard for Vacuum Circuit Breaker – IEC 62271 Guidelines, Ratings & Testing Explained

Conclusion

The IEC standard for substation earthing provides a comprehensive framework to ensure safety, equipment protection, and system stability. By adhering to these standards, engineers can design reliable earthing systems that minimize risk to personnel and equipment. From grid design to step and touch voltage calculations, the IEC standard offers clear guidance on every aspect of substation earthing. Following these standards is not just a regulatory requirement but a critical practice for maintaining a safe and efficient power system.

Proper implementation, regular testing, and maintenance ensure that the substation earthing system performs reliably throughout its operational life, safeguarding human life and valuable electrical infrastructure. The IEC standard for substation earthing remains the benchmark for engineers worldwide seeking to build safe and effective substations.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#IECStandardForSubstationEarthing, #SubstationEarthing, #ElectricalEngineering, #PowerSystemSafety, #GroundingStandards, #IECStandards, #ElectricalSafety, #EarthingDesign, #HighVoltageSafety, #SubstationDesign, #ElectricalInstallation, #PowerEngineering, #GroundingTechniques, #IndustrialEarthing, #ElectricalCompliance