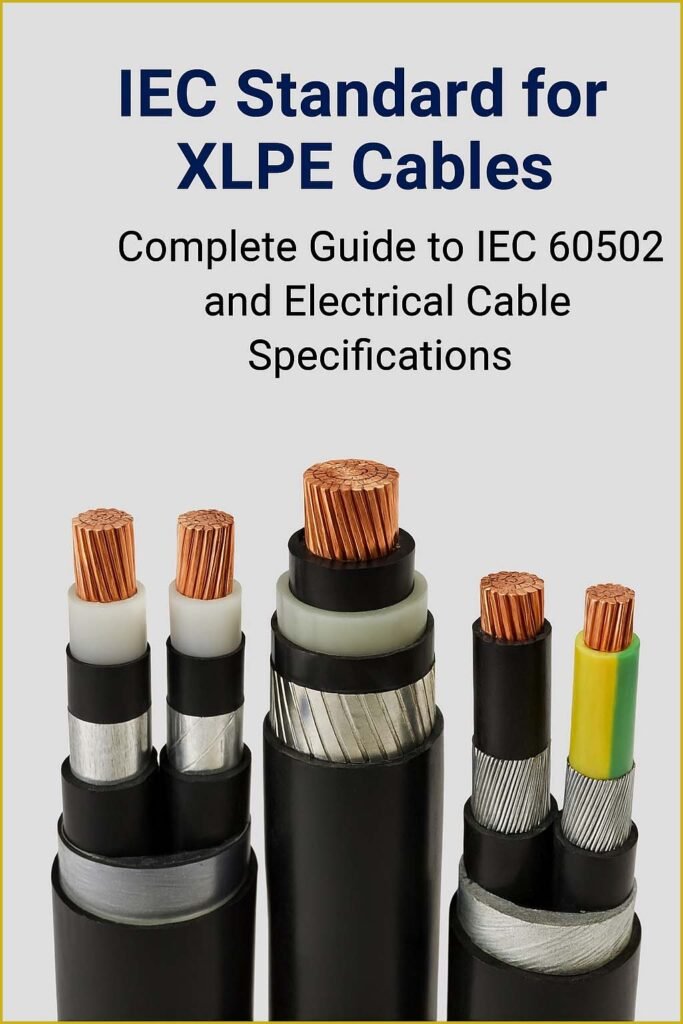

IEC Standard for XLPE Cables – Complete Guide to IEC 60502 and Electrical Cable Specifications

Cross-linked polyethylene (XLPE) cables are among the most widely used types of power cables in modern electrical installations. Their excellent electrical, thermal, and mechanical properties make them ideal for both low-voltage and high-voltage applications. To ensure safety, reliability, and performance, these cables must meet specific international standards.

Table of Contents

The most recognized global benchmark for these cables is the IEC standard for XLPE cables. This standard outlines manufacturing, testing, and installation requirements that guarantee consistent quality and long-term service performance.

Know more about iec 61439 busbar clearance

What is the IEC Standard for XLPE Cables

The IEC standard for XLPE cables refers to the guidelines developed by the International Electrotechnical Commission (IEC). These standards define the electrical, mechanical, and thermal requirements for XLPE-insulated cables used in power distribution and transmission systems. They ensure that cables perform efficiently under various environmental and operational conditions. The most commonly referenced standards are IEC 60502, IEC 60840, and IEC 62067.

These standards classify cables according to their rated voltages and application areas. IEC 60502 covers cables up to 30 kV, IEC 60840 addresses cables between 30 kV and 150 kV, and IEC 62067 covers extra-high-voltage (EHV) cables above 150 kV. Each part of the standard provides detailed testing methods, material requirements, and construction specifications.

Know more about IEC Standard for Relay Coordination – Complete Guide to Protection and Coordination Studies

Why IEC Standard for XLPE Cables is Important

The importance of the IEC standard for XLPE cables lies in consistency and safety. When a manufacturer follows IEC standards, the cable’s performance can be trusted in terms of current-carrying capacity, insulation strength, and long-term reliability. These standards are globally recognized, allowing engineers and contractors to specify and select cables with confidence.

Compliance also ensures compatibility across international projects. For instance, a cable manufactured in Europe following IEC 60502 can be safely used in Asia or the Middle East without modification. This standardization reduces procurement risks and enhances the reliability of large-scale power infrastructure.

IEC Standards Related to XLPE Cables

The IEC issues several documents that relate to XLPE cables depending on the voltage level and usage. The table below summarizes the main IEC standards and their typical applications.

| IEC Standard | Voltage Range | Application Area | Description |

|---|---|---|---|

| IEC 60502-1 | Up to 1 kV | Low voltage power distribution | Covers construction and testing of cables for fixed installations |

| IEC 60502-2 | 1 kV to 30 kV | Medium voltage systems | Specifies requirements for XLPE and EPR-insulated cables |

| IEC 60840 | 30 kV to 150 kV | High voltage power networks | Defines testing and construction of HV cables with extruded insulation |

| IEC 62067 | Above 150 kV | Extra-high voltage transmission | Details design, testing, and performance criteria for EHV cables |

| IEC 60228 | All voltage levels | Conductor standards | Specifies classes of conductors and resistance values |

| IEC 60332 | All voltage levels | Flame retardancy | Defines flame propagation tests for cables |

Know more about IEC Standard for Vibration Testing – IEC 60068 Explained with Procedures and Requirements

Key Design Requirements in IEC Standard for XLPE Cables

The IEC standard defines various construction elements that must be maintained for XLPE cables. Each part plays an essential role in ensuring safety and performance.

1. Conductor Requirements

The conductor must comply with IEC 60228. It can be made of copper or aluminum and may be stranded or compacted. The resistance values must meet the limits set in the standard to minimize power loss.

2. Insulation

The insulation layer is made of cross-linked polyethylene (XLPE). It provides excellent dielectric strength and heat resistance. The insulation must withstand temperatures up to 90°C during continuous operation and up to 250°C under short-circuit conditions.

3. Screen and Metallic Layer

Medium and high-voltage cables include a semi-conductive screen and metallic layer, often made of copper tape or wire, to control the electric field and provide grounding.

4. Outer Sheath

The outer sheath protects the cable from moisture, mechanical damage, and chemical exposure. Materials like PVC or polyethylene are commonly used.

Electrical Performance Requirements

The IEC standard for XLPE cables specifies electrical tests to confirm that the insulation can withstand operational stresses. Key tests include dielectric strength, partial discharge, and insulation resistance tests. The table below summarizes some of the critical electrical test parameters.

| Test Type | Purpose | Typical Requirement |

|---|---|---|

| Voltage Withstand Test | Ensures insulation integrity | No breakdown under rated test voltage |

| Partial Discharge Test | Detects weak insulation points | Below 5 pC for medium-voltage cables |

| Insulation Resistance | Confirms high resistance value | Greater than 1000 MΩ·km |

| Heating Cycle Test | Simulates operational load | Must not show cracks or failures |

These tests confirm that the cable can handle rated voltages safely over many years of operation.

Know more about IEC Standard for Vacuum Circuit Breaker – IEC 62271 Guidelines, Ratings & Testing Explained

Thermal and Mechanical Properties

XLPE cables must also meet stringent thermal and mechanical requirements as defined in the IEC standard for XLPE cables. The insulation and sheath must resist thermal aging, bending, and impact forces without damage.

During installation, cables often experience bending and pulling. IEC 60502 specifies minimum bending radius and maximum pulling tension to prevent internal damage. For example, a typical bending radius is 15 times the overall cable diameter.

Thermal stability is also essential. XLPE insulation has a high melting point and remains stable even at 90°C continuous operation. This property allows higher current carrying capacity compared to PVC-insulated cables.

Advantages of XLPE Cables under IEC Standards

Cables manufactured according to the IEC standard offer multiple advantages.

They provide longer service life because the insulation resists heat and moisture. Their dielectric loss is very low, which increases power transmission efficiency. These cables are lighter, making them easier to install. They can also be laid directly underground, in ducts, or even submerged in water with appropriate design.

Another major advantage is environmental safety. XLPE cables are halogen-free and produce low smoke during fire incidents. This makes them suitable for public buildings, tunnels, and industrial areas.

Testing and Quality Assurance

Manufacturers must conduct type tests, routine tests, and sample tests according to the IEC standard.

- Type Tests verify the design of the cable. These include tests for electrical, thermal, and mechanical performance.

- Routine Tests are performed on every manufactured length to ensure no defects exist.

- Sample Tests are carried out on selected lengths to confirm consistent quality.

The table below summarizes the main test categories under the IEC standard.

| Test Category | Purpose | Frequency |

|---|---|---|

| Type Tests | Confirm design compliance | Once per design type |

| Routine Tests | Ensure every cable length meets requirements | Every production batch |

| Sample Tests | Verify consistency of materials | Periodically |

All these tests ensure that cables maintain uniform quality, reducing the risk of failures in the field.

Know more about IEC Standard for Voltage Drop Calculation: Best Guide

Common Voltage Grades and Applications

XLPE cables are available in a range of voltage classes as defined by IEC. Typical grades and their applications are shown below.

| Voltage Grade | Typical IEC Standard | Common Use |

|---|---|---|

| 0.6/1 kV | IEC 60502-1 | Industrial and building wiring |

| 3.6/6 kV to 19/33 kV | IEC 60502-2 | Medium voltage distribution |

| 66 kV to 132 kV | IEC 60840 | High voltage power transmission |

| 220 kV to 500 kV | IEC 62067 | Extra high voltage transmission |

These grades ensure that engineers can select the right cable for each application, ensuring both safety and cost efficiency.

Comparison of IEC Standard with Other Standards

While the IEC standard for XLPE cables is globally recognized, other regions have their own standards such as BS (British Standard), VDE (German), and ICEA/NEMA (North American). However, most of these align closely with IEC requirements.

| Standard | Region | Equivalent IEC Range | Key Difference |

|---|---|---|---|

| BS 5467 | UK | IEC 60502-1 | Slightly different sheath test methods |

| VDE 0276 | Germany | IEC 60502-2 | Includes additional climatic tests |

| ICEA S-93-639 | USA | IEC 60840 | Uses ANSI-based testing terminology |

This global alignment ensures that IEC-compliant cables can be used worldwide with minor regional adaptations.

Future Developments in IEC Standards

As technology evolves, the IEC standard for XLPE cables continues to be updated. The latest revisions focus on enhanced environmental testing, improved fire performance, and the use of recyclable materials.

The integration of smart cable monitoring systems is also under study. These systems can track cable temperature and load in real time, providing predictive maintenance alerts. Such advancements will ensure that IEC standards remain relevant for modern energy networks.

Know more about VLF Testing vs Hipot: Best Guide on Key Differences and Applications

Conclusion

The IEC standard for XLPE cables serves as a cornerstone for cable design, manufacturing, and testing worldwide. It provides a uniform framework ensuring electrical safety, mechanical strength, and long-term reliability. Engineers and manufacturers rely on it to maintain consistency and quality in power systems from low-voltage networks to extra-high-voltage transmission lines.

By following IEC standards such as IEC 60502, IEC 60840, and IEC 62067, power utilities can ensure optimal performance, minimize losses, and extend the life of cable installations. In today’s world of expanding energy demand and renewable integration, adherence to these standards remains vital for safe, efficient, and sustainable electrical infrastructure.

Know more about cable bending radius iec standard

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#IECStandardForXLPECables, #XLPECables, #ElectricalEngineering, #PowerCables, #IECStandards, #CableTesting, #ElectricalSafety, #CableSpecification, #MediumVoltageCables, #HighVoltageCables, #IEC60502, #ElectricalInstallations, #CableInsulation, #EngineeringStandards, #ElectricalWiring