Motor Protection Circuit Breaker Applications

Motor protection circuit breaker applications are essential in both industrial and residential settings. These breakers protect electric motors from damage caused by overloads, short circuits, and phase failure. Electric motors are expensive and sensitive equipment. A fault can lead to downtime, expensive repairs, or complete motor replacement. That’s why motor protection devices are critical for electrical safety and efficiency.

The motor protection circuit breaker (MPCB) combines functions of thermal overload protection and magnetic short-circuit protection in one device. Its role goes beyond traditional circuit breakers. It ensures motors run safely, improves performance, and minimizes risks.

Understanding Motor Protection Circuit Breaker Applications

Motor protection circuit breaker applications are vast. They are commonly used in pump systems, HVAC units, conveyor belts, and compressors. Any motor-driven system benefits from the protection offered by an MPCB. These breakers monitor current flow. When abnormal conditions arise, they disconnect the motor quickly.

Motor protection circuit breakers are installed in motor control centers (MCCs) and starter panels. They help prevent faults from spreading. This ensures only the affected motor stops, keeping the rest of the system safe.

Why Motor Protection Circuit Breakers Are Important

Electric motors often face tough working environments. High starting currents, fluctuating loads, and voltage imbalances are common. These issues can lead to overheating and insulation failure. In such scenarios, Overload Relay for Motor might not be fast or precise enough. That’s where MPCBs shine. They provide instant and accurate protection.

Another major benefit is space-saving. Instead of using separate components for overload and short circuit, the MPCB combines both. It simplifies design and reduces wiring.

Types of Motor Protection Circuit Breaker Applications

MPCBs are used in various configurations. They can be applied in direct-on-line (DOL) starters, star-delta starters, or VFD systems. In DOL starters, MPCBs are connected directly before contactors. This helps isolate the motor instantly during fault conditions.

In star-delta starters, the MPCB protects both the star and delta connections. It ensures the motor receives the right current during startup and running.

In Variable Frequency Drive (VFD) systems, motor protection circuit breaker applications focus on line-side protection. Even though VFDs have built-in protection, line-side issues like surges or short circuits still need breaker protection.

Use our online tool for free Circuit Breaker Size Calculator

How Motor Protection Circuit Breakers Work

MPCBs use thermal and magnetic sensing elements. The thermal part handles overloads. If the motor draws too much current for too long, the thermal element trips the breaker. The magnetic section handles short circuits. It reacts almost instantly to very high current.

Some advanced MPCBs come with adjustable settings. Users can tune the breaker to match the motor’s full load current (FLC). This is crucial when dealing with Overload Setting for Motor to avoid nuisance tripping or under-protection.

Benefits of Using MPCBs

- Precise motor protection

- Space-saving design

- Reduced wiring and component cost

- Faster troubleshooting

- Enhanced system reliability

These benefits explain why Motor Circuit Breaker Sizing must be done carefully. Incorrect sizing can lead to either insufficient protection or constant tripping.

Applications of Motor Protection Circuit Breakers in Industrial Settings

Industries rely heavily on motors. Manufacturing plants, water treatment facilities, and chemical plants all need continuous motor operation. MPCBs are often found protecting compressors, conveyors, pumps, blowers, and mixers.

In textile and paper industries, motors run continuously under heavy loads. MPCBs ensure these machines don’t suffer from burnout during overloads or line disturbances.

In mining and construction sites, dust and moisture can cause short circuits. Here, the magnetic trip of the MPCB provides fast response, preventing equipment damage and fire hazards.

Applications in Commercial and Residential Use

While industries dominate usage, MPCBs are also used in commercial buildings. HVAC motors, lift motors, and water pumps are often protected by MPCBs.

In residential areas, though less common, some high-end homes use MPCBs to protect central water pumps and garden irrigation systems. Their compact size and high reliability make them suitable for tight spaces.

Common Technical Parameters for MPCB Selection

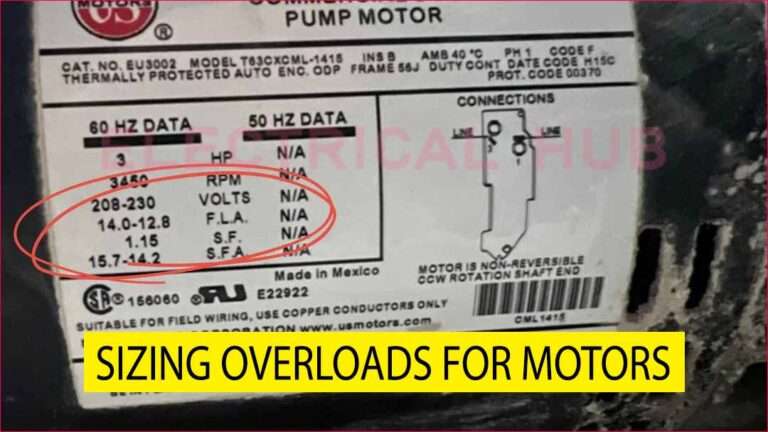

Choosing the right motor protection circuit breaker depends on several key parameters. Below is a helpful table for understanding what to consider:

| Parameter | Description |

|---|---|

| Rated Current (In) | Should match motor FLC |

| Breaking Capacity (Icu/Ics) | Must exceed system short-circuit capacity |

| Trip Class | Class 10 is common for general motors |

| Adjustable Overload Range | Helps fine-tune protection for various motor sizes |

| Phase Failure Protection | Ensures safety during line loss |

| Coordination Type | Type 1 or 2 coordination based on system requirements |

When calculating the overload setting or wire size, using a Motor Winding Wire Size Chart ensures compatibility between the breaker and motor characteristics.

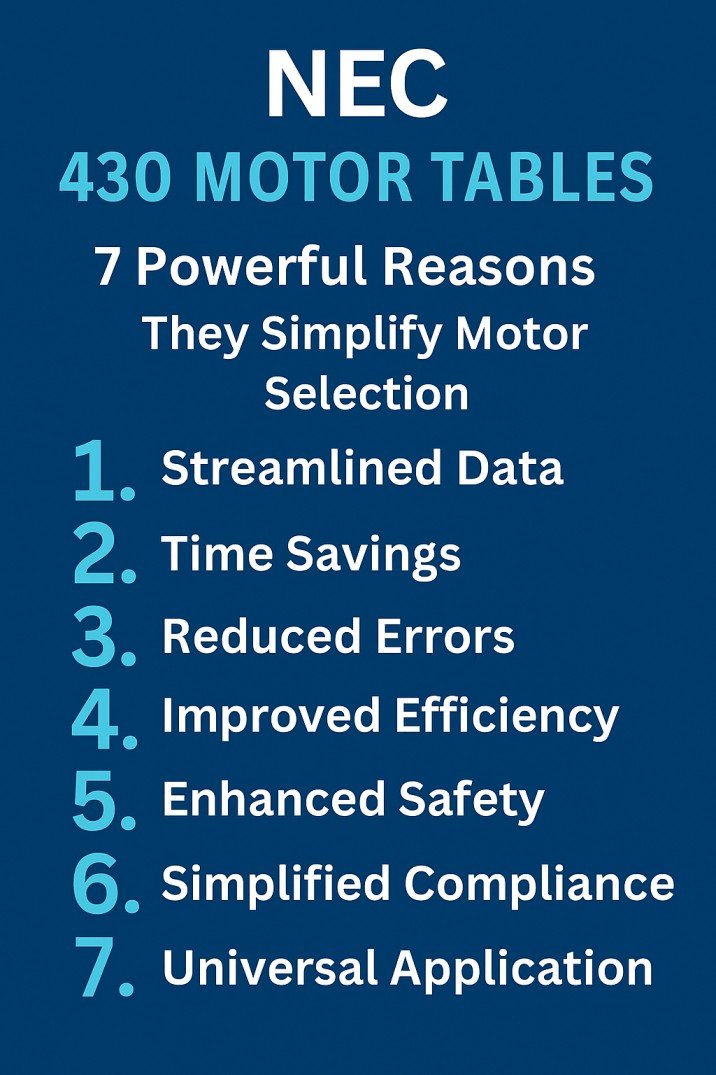

Sizing the Motor Protection Circuit Breaker

Sizing is crucial in all motor protection circuit breaker applications. A too-small breaker trips often. A too-large breaker won’t trip in time during faults.

Start with motor full load current. Add margin for inrush current if using DOL starting. Check voltage levels and system impedance. Use the following formula as a rough guide:

Breaker Size (A) = Motor FLC × 1.25

Always refer to manufacturer data and standards. Combine this sizing with insights from How to Calculate Cable Size for Motor for best results.

Connection and Installation Tips

Proper connection of an MPCB ensures long-term reliability. Always mount the breaker vertically. Make sure terminals are tightened as per torque values.

Use cable lugs if needed. Apply the proper cable size using tools like the Single Phase Motor Cable Size Calculator. This guarantees that cables do not overheat or cause voltage drop.

Avoid placing MPCBs in wet or dusty environments unless they are enclosed in IP-rated boxes.

Coordination with Other Protection Devices

MPCBs should coordinate well with upstream and downstream devices. This prevents nuisance tripping. Type 1 coordination allows damage to the starter but saves the breaker. Type 2 coordination allows both to survive faults with minimal wear.

Pairing the MPCB with a proper contactor ensures smooth motor control. Adding a Motor Circuit Breaker Sizing strategy for each motor group improves system protection.

Integration in Automation and Control Systems

In modern systems, MPCBs are not just manual devices. Many support auxiliary contacts, signaling modules, and remote trip features. These can be connected to PLCs for automation.

In Motor Protection Circuit Breaker Applications, automation helps monitor trips, send alerts, and perform diagnostics. This boosts system availability and allows for preventive maintenance.

Comparison Table: MPCB vs Traditional Protection Setup

| Feature | MPCB | Traditional Setup |

|---|---|---|

| Components | Combined | Separate (MCB + Overload Relay) |

| Space Requirement | Compact | Larger |

| Installation Time | Less | More |

| Adjustability | High | Medium |

| Cost | Moderate | May be higher overall |

| Maintenance | Easier | More complex |

This comparison shows how MPCBs provide a simplified and efficient protection approach.

Real-World Scenarios of MPCB Applications

In a water treatment plant, motors must run 24/7. A failed pump motor could disrupt the entire process. Using MPCBs ensures that faulty motors are isolated quickly. Maintenance staff can identify the fault through breaker indicators and reset only the affected section.

In a building with many fans and air-handling units, breakers help avoid complete shutdowns. Each motor has its own protection. This allows maintenance without affecting the entire HVAC system.

Conclusion on Motor Protection Circuit Breaker Applications

Motor protection circuit breaker applications cover almost every motor-driven system. Their compact design, quick reaction to faults, and ease of integration make them essential for modern electrical setups. From factories to homes, from automation to control panels, MPCBs offer unmatched protection and efficiency.

To maximize their benefits, careful attention must be given to Motor Circuit Breaker Sizing, correct wiring, and environmental conditions. Supporting tools like Single Phase Motor Cable Size Calculator, Motor Winding Wire Size Chart, and guides on How to Calculate Cable Size for Motor improve accuracy.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#MotorProtection, #CircuitBreaker, #MPCB, #ElectricalEngineering, #IndustrialAutomation, #MotorSafety, #ControlPanel, #PowerDistribution, #OverloadProtection, #ShortCircuitProtection, #ElectricalSafety, #EngineeringSolutions, #MotorControl, #ElectricalDesign, #Switchgear