IEC Standard for Busbar Sizing: Complete Guide to IEC 61439 Requirements

Understanding the IEC Standard for Busbar Sizing

When designing electrical power systems, one of the most critical aspects is selecting the right size for busbars. Busbars are the backbone of switchboards, distribution boards, and electrical panels. They carry large currents and must be properly sized to ensure safety, performance, and compliance. The IEC standard for busbar sizing provides detailed guidelines to help engineers select appropriate busbar dimensions. This ensures that systems operate reliably without overheating or causing electrical hazards.

The International Electrotechnical Commission (IEC) issues globally accepted standards that promote safety and efficiency in electrical engineering. For busbar sizing, the primary references are IEC 61439 (for low-voltage switchgear and controlgear assemblies) and IEC 60287 (for current-carrying capacity of cables). These standards specify the parameters that should be considered when sizing busbars, including current rating, short-circuit withstand capacity, temperature rise, insulation, and environmental conditions.

Why Busbar Sizing Matters

The correct sizing of a busbar is essential for several reasons. First, it prevents overheating, which could lead to insulation failure, equipment damage, or fire. Second, it ensures that the system can handle fault currents during short-circuit conditions. Third, properly sized busbars reduce power losses and improve energy efficiency. The IEC standard for busbar sizing helps engineers determine the correct dimensions to meet these requirements.

Know more about IEC Standards for Transformer Testing – Complete Guide to IEC 60076 and Testing Procedures

Undersized busbars may cause voltage drops, excessive heat, and reduced equipment life. Oversized busbars increase project costs unnecessarily. Thus, precise calculations based on standard parameters are necessary.

Key Parameters Defined in the IEC Standard for Busbar Sizing

The IEC 61439 standard defines the allowable temperature rise limits for copper and aluminum busbars under continuous load conditions. Here are the key technical parameters considered in sizing:

- Rated Current (Ir): Continuous current the busbar must carry without exceeding permissible temperature rise.

- Short-circuit Current (Isc): Maximum current the busbar can handle during a fault for a specific duration (usually 1 or 3 seconds).

- Material Type: Copper or aluminum, each having different conductivity.

- Ambient Temperature: Affects the heat dissipation capacity.

- Enclosure Type: Open-air vs enclosed, which affects cooling.

- Mounting Orientation: Vertical or horizontal position impacts air flow and cooling.

- Temperature Rise Limit: Usually 70°C for copper and 55°C for aluminum above ambient temperature.

The IEC standard for busbar sizing takes all these factors into account and provides design limits for safe operation.

Know More about IEC Standard for Air Circuit Breaker

Common Materials Used for Busbars

Busbars are usually made of copper or aluminum. Copper has better conductivity but is more expensive. Aluminum is lighter and cheaper, but it requires a larger cross-sectional area to carry the same current as copper.

| Material | Electrical Conductivity | Density | Max Temperature Rise (IEC 61439) |

|---|---|---|---|

| Copper | ~58 MS/m | 8.96 g/cm³ | 70°C |

| Aluminum | ~35 MS/m | 2.70 g/cm³ | 55°C |

The IEC standard includes correction factors for both materials to ensure accurate sizing.

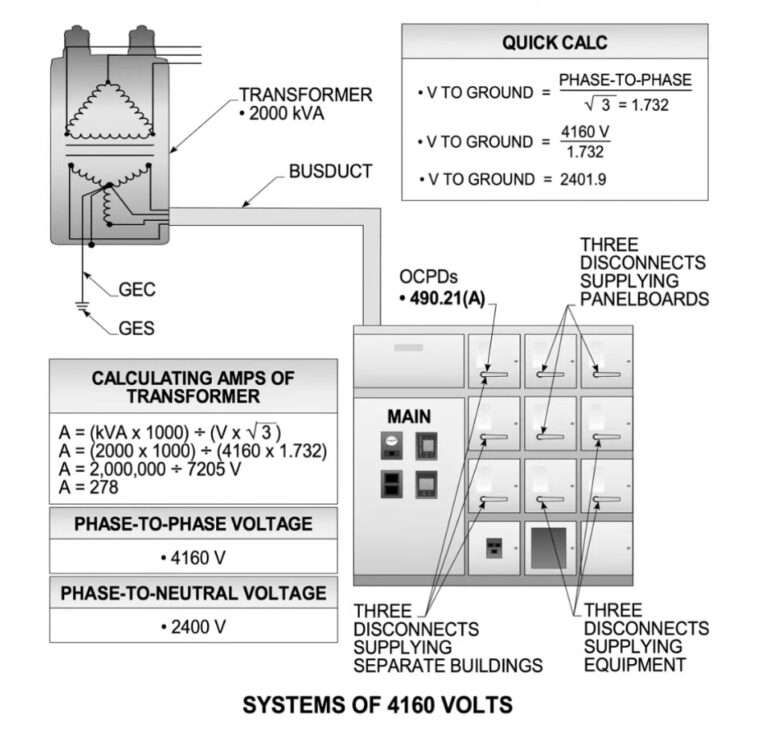

Current Carrying Capacity According to IEC 61439

The current-carrying capacity of a busbar depends on its cross-sectional area, the ambient temperature, and how it’s installed. For example, a 50 mm x 10 mm copper busbar in open air can typically carry about 1000 A, assuming an ambient temperature of 35°C and a temperature rise limit of 70°C.

The IEC standard for busbar sizing provides reference tables, but real-world conditions often differ. That’s why engineers apply derating factors based on enclosure type, ventilation, and conductor spacing.

Example:

- A copper busbar of 100 mm² may carry:

- ~270 A in enclosed panel

- ~320 A in open air

Know more about IEC Standard for XLPE CablesKnow more about

Derating factors for temperature may be:

- For 40°C ambient: 0.95

- For 50°C ambient: 0.90

Engineers multiply the nominal current by these factors to adjust sizing.

Know More about IEC Standard for Cable Lugs

Short-Circuit Withstand Capacity

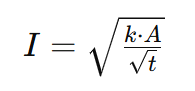

Busbars must also withstand thermal and mechanical stresses during a short circuit. The IEC standard for busbar sizing provides formulas to calculate this:

Thermal withstand (I²t):

Where:

- I = Short-circuit current (kA)

- A = Cross-sectional area (mm²)

- t = Duration in seconds (typically 1s)

- k = Material constant (approximately 143 for copper, 94 for aluminum)

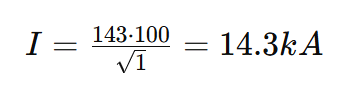

Example Calculation:

For a 100 mm² copper busbar with 1s fault duration:

This means the busbar can withstand a short-circuit current of up to 14.3 kA for 1 second.

Know More about IEC Standard for Cable Tray

Busbar Spacing and Arrangement

The IEC standard for busbar sizing also touches on clearances and creepage distances. These ensure that electrical arcs or flashovers do not occur. Key points include:

- Phase-to-phase clearance: Should meet the rated insulation voltage

- Creepage distance: Depends on the pollution degree and material group

- Busbar support spacing: Influences mechanical stability

Example support spacing for copper busbars:

- For 1000 A: around 500 mm support distance

- For 2000 A: around 400 mm

Tighter spacing improves mechanical strength but can reduce airflow, affecting temperature rise.

Practical Example: Sizing a Busbar System

Suppose you need to size a busbar for a 1600 A panel using copper in an indoor environment (35°C ambient).

- Current Rating: Use 2 x 100 mm x 10 mm copper strips in parallel

- Temperature Rise: Ensure surface area allows for adequate heat dissipation

- Short Circuit Withstand: Use formula to check if cross-section supports expected fault level

- Support Distance: Space every 400 mm for mechanical rigidity

By following the IEC standard for busbar sizing, this setup ensures the panel operates safely and efficiently under normal and fault conditions.

Know More about Contact Resistance Test IEC Standard

Additional Considerations for Busbar Design

Besides electrical properties, physical and mechanical factors must be considered:

- Electromagnetic Forces: High fault currents cause strong magnetic forces. Use clamps and supports to counteract these forces.

- Expansion and Contraction: Thermal expansion can loosen connections over time. Use flexible joints where needed.

- Ventilation: Enclosures should have sufficient airflow or forced ventilation to dissipate heat.

- Insulation Sleeves: Optional but useful in compact panels to reduce phase-to-phase risks.

IEC standards also advise on joint design, bolt torques, and use of insulating materials.

Tools and Software for Busbar Sizing

Modern engineering tools simplify the application of the IEC standard for busbar sizing. Software like Ecodial (by Schneider), Simaris (by Siemens), and ETAP provides automated calculations based on IEC guidelines. These tools let you input parameters like current, material, enclosure type, and spacing, and generate optimized busbar dimensions.

These tools ensure compliance with the latest IEC updates and significantly reduce manual errors.

Know More about Circuit Breaker Timing Test Procedure

Final Thoughts

The IEC standard for busbar sizing is a vital guideline in electrical system design. It ensures that busbars are correctly dimensioned to handle rated loads and withstand fault conditions without failure. Following this standard improves the safety, reliability, and efficiency of low-voltage power distribution systems.

Using standardized formulas, correction factors, and reference tables helps engineers make informed decisions. Whether you are designing for industrial switchgear or a commercial electrical panel, always reference IEC 61439 and related standards to ensure full compliance.

Know more about IEC Standard for Relay Coordination – Complete Guide to Protection and Coordination Studies

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#IECStandard, #BusbarSizing, #ElectricalEngineering, #PowerDistribution, #BusbarDesign, #IECStandards, #ElectricalDesign, #BusbarCalculation, #IECCompliance, #LowVoltageSystems, #HighCurrentBusbar, #SwitchgearDesign, #BusbarRating, #IndustrialElectrical, #EngineeringStandards