4 Major Differences in Bimetal Overload and Ambient-Compensated Overload Relays

Differences Between Bimetal Overload and Ambient-Compensated Overload Relays

Bimetal overload relays and ambient-compensated overload relays are both essential for protecting electric motors from overload conditions, but they have distinct operational characteristics and applications.

Table of Contents

Table of Contents

1. Basic Mechanism

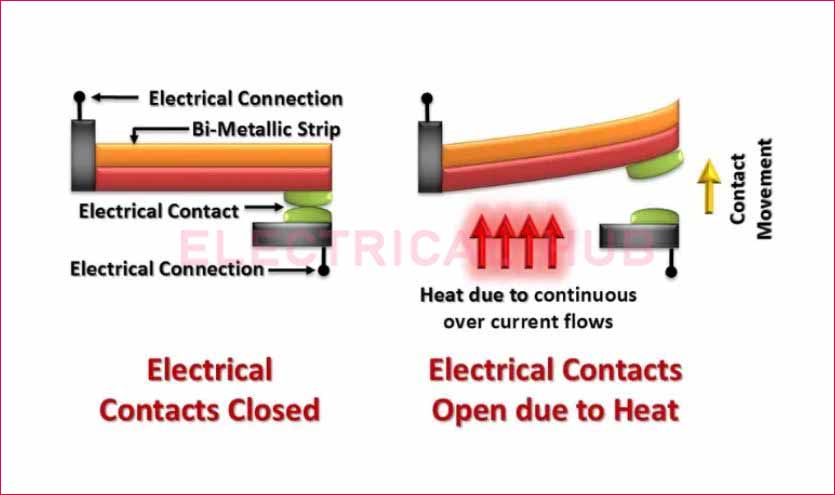

Bimetal Overload Relays: These relays operate using a bimetallic strip composed of two different metals that expand at different rates when heated. Under normal conditions, the heat generated by the motor’s current is insufficient to bend the strip. However, during an overload, the increased heat causes the strip to bend and trip the relay, disconnecting the motor from power.

Ambient-Compensated Overload Relays: These relays also use a bimetallic strip but are designed to account for variations in ambient temperature. They incorporate an additional bimetal strip that compensates for temperature changes, ensuring that the trip point remains consistent regardless of surrounding temperature fluctuations. This prevents nuisance tripping in environments with varying temperatures.

2. Temperature Sensitivity

Bimetal Overload Relays: The trip point of these relays is directly affected by ambient temperature changes. If the surrounding temperature varies significantly, it can lead to either premature tripping or failure to trip during an actual overload condition.

Ambient-Compensated Overload Relays: These are specifically engineered to maintain consistent performance even when ambient temperatures change. The design allows both bimetal strips to bend equally in response to temperature variations, isolating the effect of current flow on the primary bimetal strip responsible for tripping in overload situations.

3. Applications

Bimetal Overload Relays: Suitable for environments where temperature remains relatively stable or where slight variations do not affect performance. They are commonly used in standard motor applications without significant external temperature influences.

Ambient-Compensated Overload Relays: Ideal for applications where the motor operates in a constant ambient environment while the control unit may be exposed to varying temperatures (e.g., submersible pumps). This ensures reliable operation without false tripping due to environmental factors.

4. Cost and Complexity

Bimetal Overload Relays: Generally simpler and less expensive due to their straightforward design and operation. They are widely used in many applications where ambient compensation is not critical.

Ambient-Compensated Overload Relays: Typically more complex and may be more expensive due to their specialized design features aimed at maintaining consistent performance across varying temperatures.

Conclusion

In summary, while both bimetal and ambient-compensated overload relays for motors serve similar protective functions. They differ significantly in their sensitivity to ambient temperature, operational mechanisms, application suitability, and cost. Selecting the appropriate type depends on specific operational conditions and environmental factors affecting the motor system.

Related Posts:

- What is star delta starter

- Star Delta Starter Diagram with Timer

- Overload Setting for Motor

- Difference Between Star Delta and DOL Starter

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

BimetalOverloadRelay, #AmbientCompensatedRelay, #OverloadProtection, #MotorProtection, #ThermalOverloadRelay, #ElectricalEngineering, #IndustrialAutomation, #RelayComparison, #MotorSafety, #EngineeringBasics, #PowerSystems, #ElectricalMaintenance, #ControlCircuits, #ElectricalProtection, #MotorControl