Arc Flash Risk Assessment According to NFPA 70E

Arc flash is one of the most dangerous hazards in electrical work environments. A sudden arc flash can release a powerful burst of energy, causing severe burns, hearing damage, fire, or even death. To reduce this risk, the National Fire Protection Association developed the NFPA 70E standard. This standard helps organizations protect workers from electrical hazards through proper training, protective equipment, and thorough analysis. One of the key components of this process is the Arc Flash Risk Assessment According to NFPA 70E.

In this article, we will explore the concept of arc flash, the steps involved in conducting an arc flash risk assessment, and the specific requirements laid out in NFPA 70E.

Understanding Arc Flash and Its Dangers

An arc flash is a sudden release of electrical energy through the air when a high-voltage gap exists and breaks down. This energy release can reach temperatures of up to 35,000°F—hotter than the surface of the sun. The explosion can result in molten metal, flying debris, pressure waves, and toxic gases.

Some common causes of arc flash include:

- Loose connections

- Dropped tools

- Dust buildup

- Equipment failure

- Human error

Due to the extreme energy released, even a brief arc flash can cause life-threatening injuries. Therefore, it’s crucial to identify and evaluate risks before working on or near energized equipment. This is where the Arc Flash Risk Assessment According to NFPA 70E comes into play.

Know more about Differential Protection of Transformer

What is NFPA 70E?

NFPA 70E is a comprehensive standard for electrical safety in the workplace. It provides guidelines for safe work practices, equipment labeling, and personal protective equipment (PPE) requirements. The standard is updated every three years and focuses on reducing the risk of arc flash, arc blast, and electric shock.

NFPA 70E is not a law, but many regulatory bodies, such as OSHA in the U.S., refer to it when evaluating workplace safety compliance. The latest edition emphasizes proactive risk assessment and hazard elimination.

Importance of Arc Flash Risk Assessment According to NFPA 70E

The core objective of an arc flash risk assessment is to determine the potential for an arc flash incident and define protective measures. According to NFPA 70E, every facility must assess electrical hazards and take necessary steps to protect personnel.

Key reasons why the assessment is important:

- Identifies hazard levels

- Defines safe working boundaries

- Determines required PPE

- Ensures compliance with safety regulations

- Prevents injury and equipment damage

Without proper assessment, employees are exposed to serious risk, and the facility may be liable for failing to provide a safe work environment.

Know more about IEC Standard for Differential Protection

Key Elements of Arc Flash Risk Assessment According to NFPA 70E

NFPA 70E outlines specific procedures and components that must be included in the arc flash risk assessment. These include:

1. Collecting Electrical System Data

This is the first and most crucial step. It involves gathering information about the facility’s electrical distribution system.

Data includes:

- Single-line diagrams

- Equipment nameplate ratings

- Transformer sizes

- Breaker settings

- Cable lengths and sizes

Accurate data ensures precise calculations in the later steps.

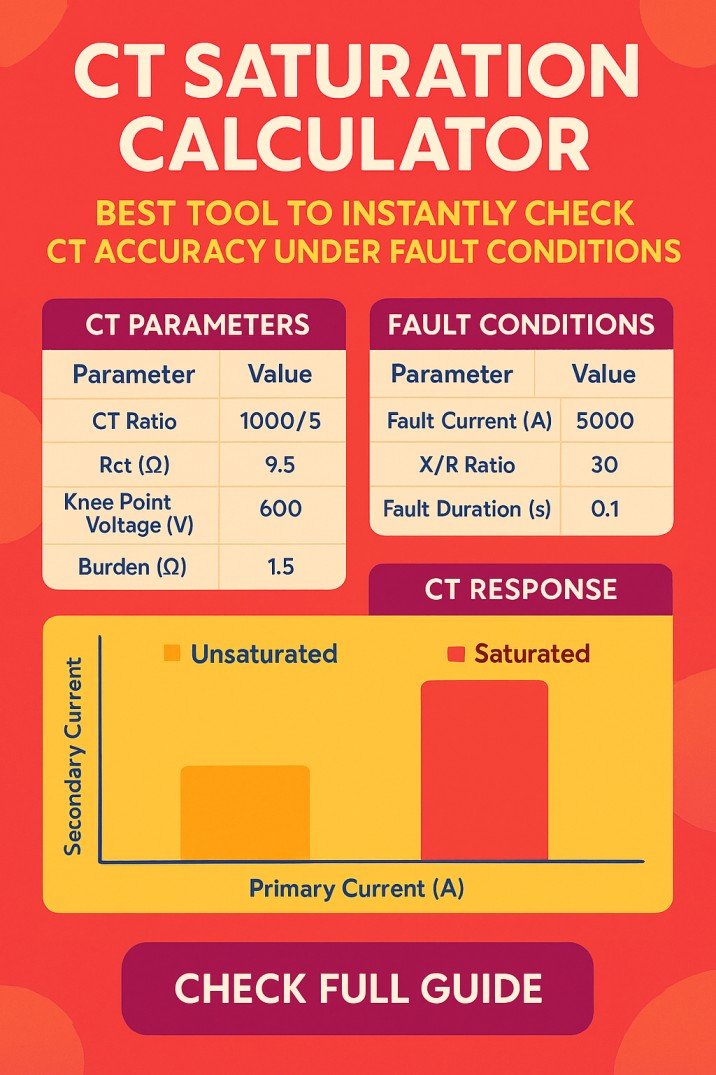

2. Performing Short Circuit and Coordination Studies

A short circuit study determines the fault current available at various points in the system. This information is essential to calculate the incident energy level during an arc flash.

A coordination study ensures that protective devices (breakers, fuses) operate correctly during faults. If not properly coordinated, a minor fault can escalate, increasing the arc flash hazard.

Know more about IEC Standard for Dry Type Transformer

3. Calculating Incident Energy

Incident energy is the amount of thermal energy (cal/cm²) a worker could be exposed to during an arc flash. NFPA 70E requires calculating this energy level at every point where work might be performed.

Common software used includes:

- ETAP

- SKM PowerTools

- EasyPower

The goal is to quantify the energy and compare it to PPE arc ratings.

4. Determining Arc Flash Boundary

The arc flash boundary is the distance from the equipment at which a worker could receive a second-degree burn if an arc flash occurs. Anyone working within this boundary must wear appropriate PPE.

The boundary is determined based on the incident energy and equipment type. It helps define safe approach distances for unqualified and qualified personnel.

Know more about IEC Standard for Busbar Clearance

5. Labeling Electrical Equipment

Once the calculations are complete, equipment must be labeled with:

- Incident energy level

- Arc flash boundary

- Required PPE

- Voltage level

- Date of assessment

These labels inform workers about the hazards and guide them in selecting the correct PPE and work practices.

6. Documenting and Reviewing

NFPA 70E requires arc flash risk assessments to be documented and reviewed every five years or whenever major system changes occur. Records should include all calculations, assumptions, and results. Keeping this documentation up to date ensures ongoing compliance and safety.

Arc Flash PPE Categories According to NFPA 70E

PPE selection is based on the incident energy levels. NFPA 70E defines four PPE categories, each with a minimum arc rating. These categories guide workers on what to wear based on the hazard.

| PPE Category | Arc Rating (cal/cm²) | Examples of PPE |

|---|---|---|

| 1 | 4 cal/cm² | Arc-rated shirt and pants, safety glasses, gloves |

| 2 | 8 cal/cm² | Category 1 + arc-rated face shield or arc hood |

| 3 | 25 cal/cm² | Full arc-rated suit with hood, gloves, boots |

| 4 | 40 cal/cm² | Heavy-duty arc-rated suit, balaclava, gloves, boots |

Selecting the correct PPE is critical to protect workers from heat and debris during an arc flash event.

Know more about IEC Standard for Battery Energy Storage System

Arc Flash Risk Assessment vs. Shock Risk Assessment

It’s important to differentiate between these two types of assessments. While they are both required under NFPA 70E, they address different hazards.

Arc Flash Risk Assessment

- Focuses on thermal burns from arc energy

- Determines incident energy and PPE

Shock Risk Assessment

- Focuses on electrical shock hazards

- Evaluates voltage exposure and required approach distances

Both assessments must be performed before any electrical work begins.

How Often Should You Update Your Arc Flash Risk Assessment?

NFPA 70E mandates a reassessment every five years or when changes are made to:

- Electrical equipment

- Protection settings

- Load profiles

- System configurations

Even small modifications can change the risk level. Periodic updates ensure that all safety measures remain effective and up to date.

Best Practices for Arc Flash Risk Assessment According to NFPA 70E

To perform a compliant and effective assessment, keep these best practices in mind:

- Use qualified electrical engineers for calculations

- Ensure field data is current and accurate

- Keep detailed documentation of all assessments

- Train all workers on arc flash hazards and PPE

- Regularly audit equipment labeling and maintenance

- Eliminate hazards where possible, not just reduce risk

By following these practices, you not only protect your workforce but also demonstrate a commitment to safety and compliance.

Conclusion

Arc Flash Risk Assessment According to NFPA 70E is a structured, technical, and essential process to prevent one of the most catastrophic incidents in electrical environments. From system analysis to equipment labeling and PPE selection, every step aims to reduce the risk of serious injuries or fatalities.

Organizations that follow the NFPA 70E standard not only comply with safety laws but also build a culture of responsibility and preparedness. With proper planning, updated assessments, and commitment to worker safety, arc flash incidents can be dramatically minimized.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#ArcFlash, #NFPA70E, #ElectricalSafety, #ArcFlashAssessment, #WorkplaceSafety, #PPE, #ElectricalHazards, #OSHACompliance, #ArcFlashStudy, #SafetyFirst, #ElectricalEngineering, #NFPACompliance, #ArcFlashProtection, #RiskAssessment, #IndustrialSafety