PLC vs Microcontroller Differences: The Ultimate Guide Engineers Wish They Had Earlier

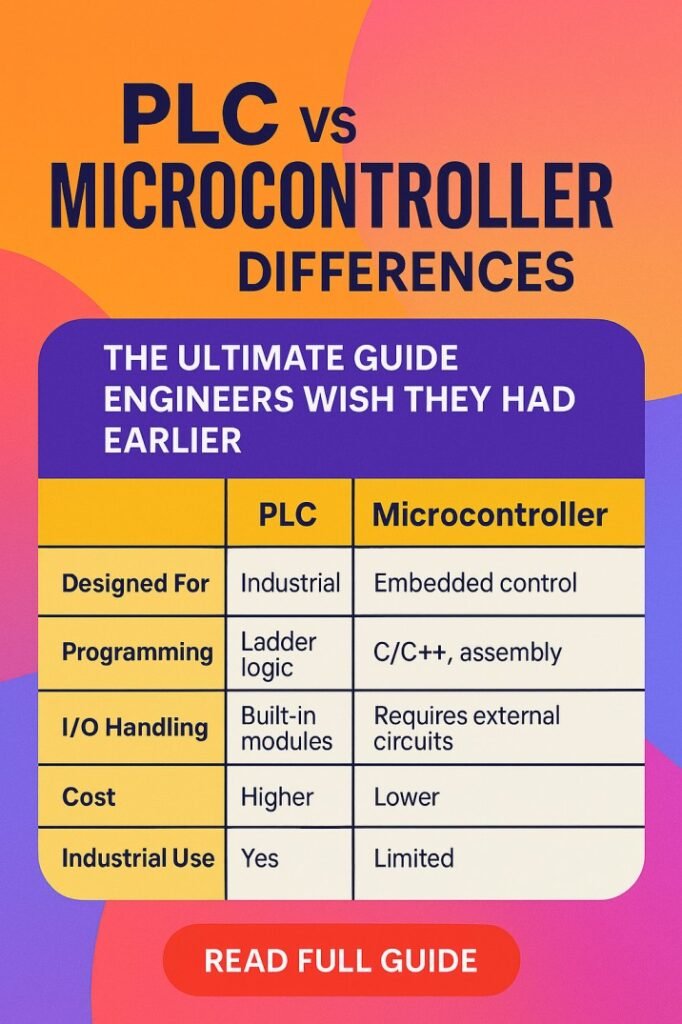

In the world of automation and control systems, one debate never seems to fade: PLC vs microcontroller differences. Engineers, students, and technicians often struggle to decide which platform fits their project best. Both are powerful in their own domains, yet they serve very different purposes. Choosing the wrong one can lead to higher costs, complex redesigns, and long-term maintenance headaches.

Table of Contents

Understanding PLC vs microcontroller differences early can save time, money, and frustration. Whether you are designing an industrial production line, a smart home device, or a custom embedded system, the decision between these two technologies shapes everything from hardware design to software complexity.

Let’s break it down in a clear, practical way so you can confidently choose the right control solution for your next project.

What Is a PLC?

A Programmable Logic Controller, commonly called a PLC, is an industrial-grade digital computer used for automation of electromechanical processes. You’ll find PLCs running conveyor belts, packaging machines, water treatment plants, and entire manufacturing lines.

Free PLC Ladder Logic Simulator – Best Tools to Practice PLC Programming Online

PLCs are designed to survive harsh industrial environments. They can handle electrical noise, vibration, temperature changes, and continuous operation for years without failure. When discussing PLC vs microcontroller differences, durability and reliability are always major points.

Key characteristics of PLCs include:

• Rugged hardware built for industrial use

• Modular design with expandable input/output modules

• Easy integration with sensors, motors, and actuators

• Programming using ladder logic, function block, or structured text

• Strong focus on safety and real-time control

PLCs are built for engineers who need dependable automation rather than low-level hardware design.

What Is a Microcontroller?

A microcontroller is a compact integrated circuit designed to govern a specific operation in an embedded system. It includes a processor, memory, and input/output peripherals on a single chip. Microcontrollers power devices like washing machines, remote controls, medical devices, IoT sensors, and automotive electronics.

When analyzing PLC vs microcontroller differences, flexibility is where microcontrollers shine. They allow deep control over hardware behavior, communication protocols, and power consumption.

Explore everything about Automation Engineer Certification Cost in 2026 – Fees, Duration & Best Value Programs

Typical features of microcontrollers include:

• Small size and low power consumption

• Direct control of pins and peripherals

• Programming in C, C++, or assembly

• Wide variety of communication interfaces like UART, SPI, and I2C

• Ideal for embedded systems and custom electronics

Microcontrollers are perfect when you need a tailored solution rather than a plug-and-play industrial controller.

Core Purpose: Industrial Automation vs Embedded Control

One of the most important PLC vs microcontroller differences is their intended application.

PLCs are purpose-built for industrial automation. They focus on reliability, ease of maintenance, and compatibility with industrial sensors and actuators. Their design assumes electricians and technicians will maintain them, not just embedded engineers.

Microcontrollers, on the other hand, are designed for embedded control inside products. They are part of the electronics rather than a standalone industrial controller. They suit consumer electronics, automotive modules, and smart devices.

SCADA vs DCS Comparison: Best Professional Guide for Engineers

Here’s a quick comparison:

| Aspect | PLC | Microcontroller |

|---|---|---|

| Primary Use | Industrial automation | Embedded systems |

| Environment | Harsh industrial | Controlled or product-level |

| Users | Automation engineers, technicians | Embedded engineers, designers |

| System Type | Standalone controller | Part of a custom circuit |

This table highlights a major theme in PLC vs microcontroller differences: environment and application define the choice.

Hardware Design Differences

Hardware architecture is another key area where PLC vs microcontroller differences become obvious.

A PLC is a complete, ready-to-use system. It includes a CPU, power supply, input/output modules, and communication ports in a single enclosure or modular rack. You don’t design the electronics; you just wire field devices to terminals.

A microcontroller is only one chip on a circuit board. You must design the entire supporting hardware, including:

• Power regulation

• Input signal conditioning

• Output drivers

• Protection circuits

• Communication interfaces

This means microcontroller projects demand strong electronics knowledge, while PLC projects focus more on wiring and system integration.

Explore everything about Automation Engineer Certification Cost in 2026 – Fees, Duration & Best Value Programs

| Hardware Feature | PLC | Microcontroller |

|---|---|---|

| Form Factor | Industrial module or rack | Single IC on PCB |

| Signal Levels | Industrial voltage (24V, 230V) | Low voltage (3.3V, 5V) |

| Protection | Built-in isolation and filtering | Must be designed externally |

| Expansion | Easy with I/O modules | Requires PCB redesign |

These hardware-related PLC vs microcontroller differences directly affect project complexity.

Programming Style and Tools

Software development is where many beginners first notice PLC vs microcontroller differences.

PLCs are programmed using languages defined in the IEC 61131-3 standard. The most popular is ladder logic, which looks similar to electrical relay diagrams. This makes it easier for electricians and technicians to understand and troubleshoot.

Common PLC languages include:

• Ladder Diagram (LD)

• Function Block Diagram (FBD)

• Structured Text (ST)

• Sequential Function Chart (SFC)

Microcontrollers are usually programmed in C or C++. The programmer must manage memory, interrupts, and hardware registers directly. This offers high flexibility but requires deeper technical expertise.

Know more about PLC vs DCS: Main Differences for Industrial Automation

| Programming Aspect | PLC | Microcontroller |

|---|---|---|

| Languages | Ladder, FBD, ST | C, C++, Assembly |

| Learning Curve | Easier for automation techs | Steeper, more technical |

| Debugging | Online monitoring tools | Serial debug, JTAG, logs |

| Hardware Control | Abstracted | Direct register-level control |

These software-related PLC vs microcontroller differences influence who can maintain the system long term.

Reliability and Industrial Safety

Reliability is one of the biggest PLC vs microcontroller differences in real-world use.

PLCs are designed for 24/7 operation in factories. They include built-in protection against electrical noise, voltage spikes, and temperature variations. Many PLC systems also support redundant CPUs and power supplies.

Microcontrollers can be reliable, but only if the hardware and firmware are carefully designed. In industrial environments, you must add extra protection circuits, watchdog timers, and isolation.

Safety features also differ:

• PLCs often support safety-rated modules and emergency stop integration

• Microcontroller systems need external safety relays and certified circuits

• PLC firmware is typically validated for industrial use

• Microcontroller firmware quality depends entirely on the developer

Know more about SCADA HMI Software Cost in 2026 – Pricing, Licenses & Best Value Options

This makes reliability a decisive factor when comparing PLC vs microcontroller differences for critical applications.

Cost Considerations

Cost is another area where PLC vs microcontroller differences strongly impact decisions.

PLCs have higher upfront costs. Industrial I/O modules, communication cards, and branded software licenses add to the price. However, they reduce engineering time and maintenance complexity.

Microcontrollers are very inexpensive per unit, especially in mass production. But development costs can be high due to custom PCB design, firmware development, and testing.

| Cost Factor | PLC | Microcontroller |

|---|---|---|

| Initial Hardware Cost | High | Low |

| Development Time | Shorter | Longer |

| Maintenance Cost | Lower in industry | Depends on design |

| Best For | Low to medium volume industrial systems | High volume embedded products |

So, in PLC vs microcontroller differences, PLCs win for quick industrial deployment, while microcontrollers win in large-scale product manufacturing.

Know more about PLC Programming Salary 2026 – Experience-Wise Pay, Country Comparison & Skills That Boost Income

Flexibility and Customization

Flexibility is where PLC vs microcontroller differences lean heavily toward microcontrollers.

PLCs are somewhat limited to the manufacturer’s ecosystem. You choose from available modules and supported protocols. Custom hardware features are difficult to add.

Microcontrollers allow complete customization. You can design unique communication interfaces, add wireless connectivity, or optimize for ultra-low power consumption.

However, this flexibility comes with increased design responsibility and longer testing cycles.

Maintenance and Troubleshooting

Maintenance is often overlooked when studying PLC vs microcontroller differences, but it is crucial in industrial environments.

PLCs are built for easy troubleshooting. Technicians can monitor inputs, outputs, timers, and internal bits in real time using vendor software. Faulty modules can be replaced quickly.

Microcontroller-based systems are harder to troubleshoot in the field. Diagnosing issues may require firmware updates, oscilloscopes, or specialized debugging tools.

For factories that cannot afford long downtime, PLC vs microcontroller differences in maintenance strongly favor PLCs.

Communication and Networking

Modern control systems rely heavily on communication networks. PLC vs microcontroller differences also appear here.

PLCs commonly support industrial protocols such as:

• Modbus

• Profibus

• Profinet

• Ethernet/IP

• CANopen

Know more about Modbus Communication Protocol: Master-Slave Explained

Microcontrollers support communication too, but often at a lower level. Engineers must implement protocol stacks in firmware or use external modules.

While both can connect to SCADA, HMI, and cloud systems, PLCs make industrial networking simpler and more standardized.

When to Choose a PLC

A PLC is usually the better option when:

• The environment is industrial and electrically noisy

• Maintenance will be done by technicians, not embedded engineers

• Safety and reliability are critical

• The system must integrate with industrial networks

• Development time must be short

In these cases, PLC vs microcontroller differences clearly point toward PLCs.

When to Choose a Microcontroller

A microcontroller is often ideal when:

• You are designing a compact electronic product

• Power consumption must be low

• Hardware must be highly customized

• Unit cost must be minimized in large production

• Advanced algorithms or signal processing are required

Know more about OPC UA vs MQTT: Protocol Comparison for Industrial Control

Here, PLC vs microcontroller differences favor microcontrollers for flexibility and cost efficiency.

Final Thoughts

Understanding PLC vs microcontroller differences is not about deciding which one is better overall. It is about choosing the right tool for the job. PLCs dominate in industrial automation where reliability, safety, and easy maintenance matter most. Microcontrollers lead in embedded systems where customization, size, and cost are critical.

Engineers who master PLC vs microcontroller differences can design smarter systems, avoid unnecessary complexity, and deliver solutions that last. The right choice at the beginning of a project can prevent months of redesign and years of maintenance challenges.

Know more about Industrial IoT Sensors in Automation: Cost and Integration

When you evaluate your next control system, think about environment, users, scalability, and long-term support. That is where the real impact of PLC vs microcontroller differences becomes clear.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#PLCvsMicrocontroller #IndustrialAutomation #EmbeddedSystems #ControlSystems #PLCProgramming #MicrocontrollerProjects #AutomationEngineering #ElectronicsEngineering #SCADA #IoTvsPLC