Cable Gland Size Chart Hawke: Best NEC-Compliant Sizing & Industrial Application Guide

Cable glands play a vital role in industrial electrical installations, ensuring the safe termination and sealing of cables in control panels, machinery, and hazardous areas. For engineers, electricians, and designers, selecting the correct cable gland is not just about fitting a cable, it directly impacts system reliability, safety, and compliance with standards.

Table of Contents

The cable gland size chart Hawke serves as an essential reference, helping professionals choose the appropriate gland based on cable diameter, type, and installation environment. In this guide, we will explore Hawke cable gland sizing in detail, provide NEC-compliant guidelines, and discuss practical applications in industrial settings.

Use our online tool for free Sub Panel Breaker Size Calculator – Find the Right Breaker for Your Electrical Sub Panel

Understanding Cable Glands

Cable glands are mechanical devices designed to attach and secure the end of a cable to electrical equipment. They provide strain relief, environmental sealing, and maintain the integrity of electrical enclosures against dust, moisture, or explosive atmospheres. Hawke cable glands are widely recognized for their durability, precision engineering, and compliance with international standards such as IEC, NEC, and ATEX for hazardous locations.

Selecting the correct gland is critical. An undersized gland can damage the cable insulation, create loose connections, and lead to safety hazards. An oversized gland may compromise the sealing properties, allowing ingress of dust or water. The cable gland size chart Hawke is the industry standard tool that ensures engineers select the right gland for a given cable type and diameter.

How to Use a Cable Gland Size Chart Hawke

The cable gland size chart Hawke categorizes glands according to their thread size, type (such as metric or PG), and the range of cable diameters they can accommodate. Here’s how to effectively use the chart:

- Measure the cable diameter: Use a vernier caliper or cable sizing tool to determine the outer diameter of the cable. Include all insulation, screens, and sheaths in the measurement.

- Identify cable type: Determine if the cable is single-core, multi-core, armoured, or unarmoured, as this affects gland selection.

- Select thread size and type: Match the cable diameter with the corresponding gland entry size in the Hawke chart. Choose metric threads for IEC compliance or PG threads for traditional installations.

- Check for environmental requirements: If the installation is in a hazardous area, ensure the gland is rated for flameproof or Ex-proof standards.

Use our online tool for free Sub Panel Wire Size Calculator – Accurate Wire Gauge & Load Sizing Tool

NEC Compliance and Cable Glands

The National Electrical Code (NEC) sets guidelines for cable terminations and gland usage to ensure safety and prevent fire hazards. Key NEC requirements related to cable glands include:

- Strain relief: Glands must prevent mechanical strain on cable conductors.

- Environmental protection: Glands must maintain enclosure integrity against moisture and dust.

- Cable diameter range: Only glands that match the actual cable diameter should be used. Oversizing or undersizing violates NEC standards.

- Material selection: For corrosive or outdoor environments, glands must be made of suitable metals like stainless steel or corrosion-resistant alloys.

By following the cable gland size chart Hawke, engineers ensure their installations are NEC-compliant and safe for industrial operations.

Industrial Applications of Hawke Cable Glands

Hawke cable glands are engineered for a range of industrial applications, including:

- Process and manufacturing plants: To protect control and power cables in harsh environments with exposure to chemicals, moisture, or vibration.

- Oil, gas, and petrochemical industries: Explosion-proof and flameproof glands provide safety in hazardous zones.

- Marine and offshore installations: Corrosion-resistant glands ensure long-term performance in saltwater and humid environments.

- Renewable energy plants: Wind turbines and solar installations require robust glands that can withstand outdoor conditions and UV exposure.

Using the cable gland size chart Hawke, engineers can select glands that match both the cable specifications and environmental requirements, reducing downtime and maintenance costs.

Use our online tool for free Sub Panel Sizing Calculator: Best Tool to Use

Common Types of Hawke Cable Glands

Hawke manufactures a wide range of cable glands to suit different cable types and industrial standards. These include:

- Standard PG or Metric glands: Suitable for general-purpose indoor and outdoor applications.

- Ex e/Ex d glands: Flameproof and increased safety glands for hazardous zones.

- Armoured cable glands: Designed to terminate steel wire armoured (SWA) or aluminum wire armoured (AWA) cables securely.

- Mini or compact glands: Used in confined spaces where space-saving solutions are necessary.

Selecting the right type requires careful reference to the cable gland size chart Hawke, considering both cable diameter and the specific application. Use our online tool for free Wire Size Calculator for Subpanels and Feeders – NEC Guidelines Included

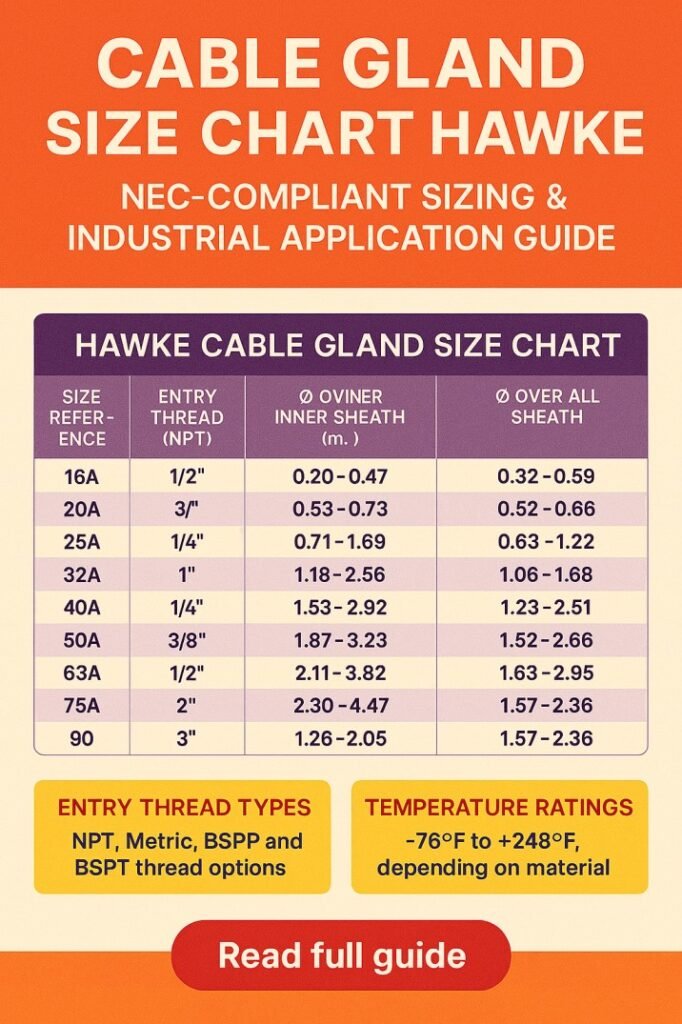

Hawke Cable Gland Size Chart

Below is a simplified version of the cable gland size chart Hawke for quick reference. This chart lists common metric thread sizes, the corresponding cable diameter ranges, and typical applications.

| Hawke Gland Thread Size | Cable Diameter (mm) | Recommended Application |

|---|---|---|

| M16 | 4 – 10 | Control circuits, lighting, instrumentation |

| M20 | 6 – 12 | Small power cables, signal wiring |

| M25 | 10 – 18 | Medium power cables, industrial panels |

| M32 | 16 – 22 | Machinery cables, motor connections |

| M40 | 20 – 28 | Distribution boards, medium power supply |

| M50 | 26 – 36 | High current cables, switchgear installations |

| M63 | 32 – 45 | Large power cables, industrial equipment |

| M75 | 42 – 55 | Heavy-duty power cables, hazardous zones |

| M90 | 50 – 65 | Very large cables, main feeders, process plants |

This chart ensures engineers can quickly identify the right gland for a cable diameter while maintaining NEC compliance.

Know more about Industrial Control Panel Design Software – Best Tools, Features & Pro Tips for Engineers

Tips for Selecting the Correct Cable Gland

To optimize performance and safety, consider the following tips when using the cable gland size chart Hawke:

- Always measure cable diameter accurately, including insulation, sheathing, and any armoring.

- Account for environmental conditions like temperature, moisture, and corrosive exposure.

- For hazardous areas, use only glands certified for the required zone (Ex e, Ex d, or Ex n).

- Ensure the gland’s material matches the installation environment to avoid corrosion or mechanical failure.

- Check that the gland’s entry size accommodates multiple cables if bundling is required.

By following these steps, engineers can avoid common installation errors, such as loose connections, ingress failures, and premature wear. Use our online tool for free Electrical Panel Upgrade Cost Calculator: Best Tool

Advantages of Using Hawke Cable Glands

Hawke cable glands offer several advantages for industrial installations:

- Precision engineering: Accurate fit reduces mechanical stress on cables.

- Wide range of sizes: Covers virtually all cable diameters and thread types.

- Compliance with standards: Meets NEC, IEC, and ATEX requirements.

- Durability: Resistant to impact, corrosion, and environmental hazards.

- Ease of installation: Simplifies field installation with clear sizing charts and user-friendly design.

These advantages make Hawke cable glands the preferred choice for engineers who value reliability, safety, and compliance.

Know more about Cable Size Chart Gland Guide for Engineers: NEC-Compliant Sizing, Selection & Best Applications

Maintenance and Inspection Guidelines

Even after proper installation, cable glands require periodic inspection and maintenance to ensure long-term reliability:

- Check for signs of corrosion, cracks, or deformation.

- Ensure gland tightness and secure connection to prevent loosening due to vibration.

- Verify that the sealing ring or O-ring remains intact and provides environmental protection.

- Inspect the cable for insulation damage at the termination point.

- Replace any worn or damaged glands immediately to maintain NEC compliance.

Following these practices extends the life of both cables and electrical equipment while preventing safety hazards.

Use this tool if you are trying to calculate cable size for underground cables. Try here Underground Cable Size Calculator – Find Correct Wire Size for Long Distance Runs

Conclusion

Selecting the right cable gland is a crucial step in ensuring the safety, reliability, and compliance of industrial electrical installations. The cable gland size chart Hawke is an indispensable tool for engineers, offering clear guidance on cable diameter, thread size, and environmental suitability. By understanding cable types, NEC requirements, and industrial applications, professionals can make informed decisions, reduce maintenance costs, and ensure long-term operational efficiency.

Whether you are working in manufacturing plants, oil and gas facilities, offshore installations, or renewable energy projects, referring to the cable gland size chart Hawke ensures that your installations are safe, compliant, and built to last. Proper selection, installation, and maintenance of cable glands contribute directly to system performance and safety, making it a critical consideration in all industrial electrical projects.

Explore our professional online tool for quick calculations kw to cable size calculator

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#cableglandsizecharthawke, #cableglands, #electricalengineering, #NECcompliance, #industrialwiring, #cablesizing, #electricalinstallation, #hazardousareaglands, #hawkeequipment, #professionalcontractors