NEC 430 Motor Tables: 7 Powerful Reasons They Simplify Motor Selection

Selecting the right motor equipment can feel overwhelming, especially when dealing with varying horsepower ratings, conductor sizes, overload protection, and full-load current values. This is where NEC 430 Motor Tables make the process easier, clearer, and more reliable. These tables guide engineers, installers, and maintenance teams with standardized values that remove guesswork. They also improve safety and compliance. Many professionals rely on them every day because they offer consistent reference values when designing or upgrading motor systems.

Table of Contents

Understanding how NEC 430 Motor Tables work is essential for efficient motor sizing. The tables provide important data points needed for conductors, overload relays, protective devices, and circuit breakers. They also ensure that motor circuits follow accepted electrical codes. When used correctly, they simplify decisions that might otherwise require deep calculations. This is especially helpful for industrial facilities, commercial buildings, and workshops where motors run critical operations.

Know more about IEC Standards for Transformer Testing – Complete Guide to IEC 60076 and Testing Procedures

In this detailed guide, you will learn seven powerful reasons these tables make motor selection easier. You will also see examples and tables to improve understanding.

Why NEC 430 Motor Tables Matter in Motor System Design

Motor circuits require careful planning. A small mistake in sizing can lead to overheating, nuisance tripping, or premature equipment failure. NEC 430 Motor Tables help avoid these problems by giving reliable current values that apply to a wide range of installations. This keeps systems consistent, reduces design errors, and ensures that motor circuits follow proper standards.

Their purpose is not to give exact motor nameplate values but to offer standardized currents for calculations. This approach prevents undersized wiring and improves system reliability. With the right interpretation, these tables make motor selection far more efficient than relying on individual nameplate data alone.

1. They Provide Standardized Full-Load Current Values

One of the biggest advantages of NEC 430 Motor Tables is the availability of standard full-load current ratings. These values are organized by horsepower and voltage. They ensure that conductor sizing, breaker selection, and protection settings follow standardized currents instead of fluctuating nameplate values.

Know more about IEC Standard for XLPE Cables – Complete Guide to IEC 60502 and Electrical Cable Specifications

This consistency is important because different manufacturers publish different current ratings. The tables bring uniformity across all installations.

Sample Reference Table for Full-Load Current

| Horsepower | Voltage (3-Phase) | Full-Load Current (A) |

|---|---|---|

| 3 HP | 230V | 9.6 A |

| 5 HP | 460V | 7.6 A |

| 10 HP | 230V | 28 A |

| 20 HP | 460V | 27 A |

These values help avoid confusion and improve code compliance instantly.

Know more about IEC Standard for Voltage Drop Calculation: Best Guide

2. They Simplify Conductor Sizing

Proper conductor sizing is essential for motor efficiency and long-term performance. NEC 430 Motor Tables give the full-load current needed to size wires correctly according to the National Electrical Code. Without these tables, technicians would need to measure or calculate current manually, which takes time and increases the chance of errors.

The tables also guide users toward the correct ampacity rating, ensuring the chosen conductor can handle both normal current and starting current. This makes it easier to maintain voltage stability and prevent cable overheating.

Know more about IEC Standard for Relay Coordination – Complete Guide to Protection and Coordination Studies

Typical Conductor Selection Table

| Motor HP | FLC (A) | Required Conductor (Cu) | Minimum Ampacity |

|---|---|---|---|

| 7.5 HP | 22 A | 10 AWG | 27.5 A |

| 15 HP | 42 A | 6 AWG | 52.5 A |

| 25 HP | 68 A | 4 AWG | 85 A |

This makes conductor selection straightforward, even for new technicians.

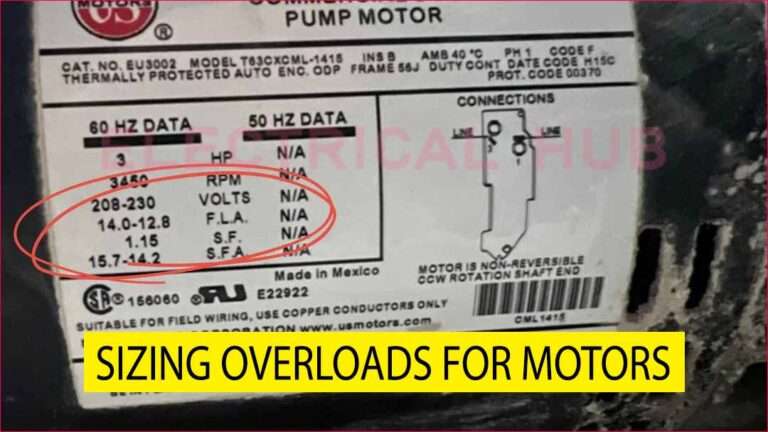

3. They Improve Overload Protection Accuracy

Overload protection is essential for motor longevity. When current rises beyond safe operating conditions, overload devices must react quickly. By using standardized full-load currents from NEC 430 Motor Tables, installers can set overload relays accurately without guesses.

The tables ensure that overload settings meet NEC requirements. This protects motors from thermal damage, winding failure, and expensive downtime. Accurate overload protection also extends motor lifespan, reducing maintenance and replacement costs.

4. They Help in Selecting Proper Overcurrent Devices

Choosing the right breaker or fuse is critical for motor safety. Oversized protective devices fail to protect equipment, while undersized ones cause nuisance tripping. NEC 430 Motor Tables help determine the correct full-load current values needed for calculating breaker size using NEC formulas.

Know more about IEC Standard for Vibration Testing – IEC 60068 Explained with Procedures and Requirements

This is extremely useful because motor circuits have unique requirements. Motors often draw high inrush currents when starting. The tables help select the right protective device that allows starting current but still protects the circuit from faults.

Breaker Sizing Reference

| Motor Size | FLC (A) | Max Breaker % | Breaker Rating |

|---|---|---|---|

| 10 HP | 28 A | 250% | 70 A |

| 15 HP | 42 A | 250% | 105 A |

This approach reduces trial-and-error and speeds up design work.

5. They Eliminate Guesswork in Motor Feeder Sizing

Motor feeders must be sized based on the largest motor plus additional loads. NEC 430 Motor Tables make this easier by providing dependable current values for each connected motor. With clear reference currents, designers can calculate feeder capacity more accurately, leading to better planning for distribution panels, MCCs, and control systems.

When designing multi-motor systems, these tables save time by delivering ready-made data. This improves coordination between feeders, controllers, and protective devices, ensuring reliable operation.

Know more about IEC Standard for Vacuum Circuit Breaker – IEC 62271 Guidelines, Ratings & Testing Explained

6. They Ensure Better Compliance and Safer Installations

Electrical codes exist to keep systems safe. NEC 430 Motor Tables form the foundation for safe motor circuit design by preventing undersized wiring, improper overload protection, and incorrect breaker ratings. Following these tables helps meet inspection requirements and reduces the risk of electrical fires, cable burnout, or equipment failure.

Compliance also builds confidence when working in industrial environments where motors operate continuously. The standardized data helps engineers maintain consistency across installations.

7. They Speed Up Motor Selection and Reduce Errors

Many electricians and engineers appreciate how much time they save using NEC 430 Motor Tables. Without these tables, they would need to check every motor nameplate, convert horsepower, and calculate wire sizes. The tables remove steps and reduce mistakes by offering organized, ready-to-use values.

Use our online tool Electricity Load Calculator (kVA) According to IEC and NEC

This is especially helpful in large motor systems, such as factories, water treatment plants, and HVAC installations. The reduced error rate also leads to smoother inspections, fewer revisions, and more reliable electrical systems.

Conclusion

NEC 430 Motor Tables offer powerful benefits for anyone involved in motor installation, maintenance, or design. They provide standardized full-load currents, simplify conductor sizing, enhance overload protection, support accurate overcurrent device selection, and improve overall safety. They also speed up system design and minimize costly errors. These advantages make the tables essential for building dependable motor circuits.

Whether you work in industrial automation, building services, or electrical contracting, using NEC 430 Motor Tables will make your job easier, more accurate, and fully compliant. They remain one of the most important tools for safe and efficient motor selection, and their value continues to grow as modern systems become more complex.

Use our online tool MM to AWG Wire Size Calculator According to IEC and NEC

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#NEC430, #MotorTables, #MotorSizing, #ElectricalCode, #MotorProtection, #NECCompliance, #IndustrialElectrical, #MotorDesign, #ElectricalSafety, #EngineeringStandards