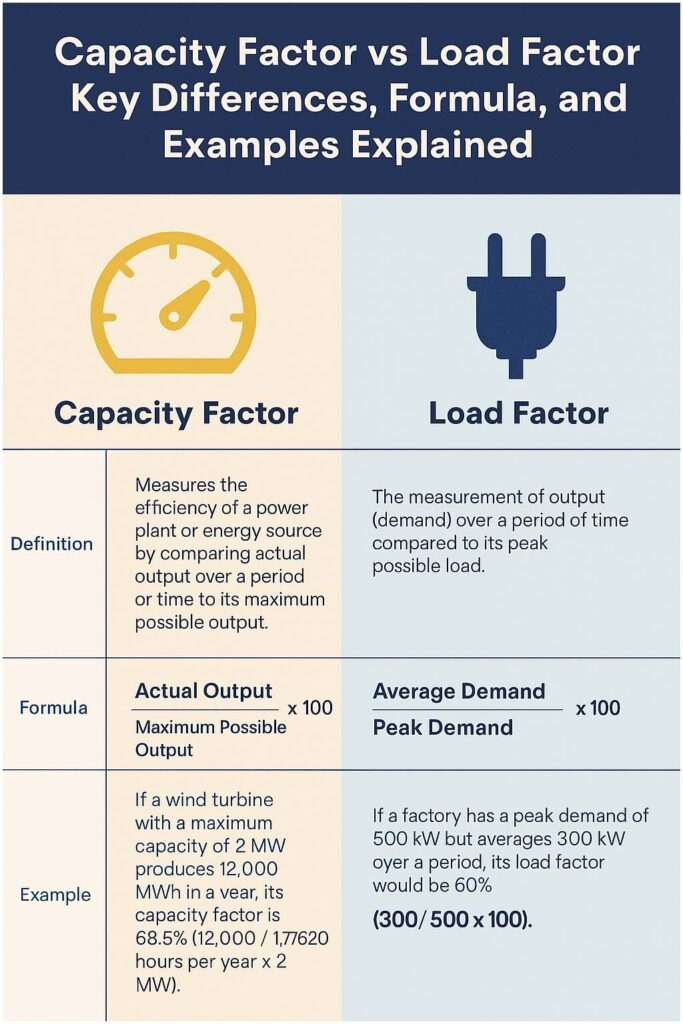

Capacity Factor vs Load Factor – Key Differences, Formula, and Examples Explained

Understanding the difference between capacity factor and load factor is essential in the energy and power sector. These two terms are often used when analyzing the performance of power plants, renewable energy systems, and electrical utilities. While they may sound similar, they measure different aspects of efficiency and utilization. In this article, we will explore capacity factor vs load factor in detail, explain their formulas, show examples, and highlight their significance in practical energy applications.

Table of Contents

What is Capacity Factor

The capacity factor measures how efficiently a power plant generates energy compared to its maximum potential. It represents the ratio of the actual energy produced over a period of time to the energy that could have been produced if the plant operated at full capacity during the same period.

The capacity factor shows how much a power plant is being used relative to its full output capability. A high capacity factor means that the power plant is generating energy close to its maximum possible output.

Formula for Capacity Factor

Capacity Factor = (Actual Energy Produced in a Given Time) / (Maximum Possible Energy Output in the Same Time)

Example of Capacity Factor

Suppose a 100 MW wind power plant produces 219,000 MWh of electricity in a year. The total possible energy generation in a year, if it ran at full capacity, would be:

100 MW × 24 hours × 365 days = 876,000 MWh

Now, the capacity factor can be calculated as:

Capacity Factor = 219,000 / 876,000 = 0.25 or 25%

This means the wind plant operated at 25% of its total capacity on average throughout the year.

Know more about IEC Standard for Generator Protection – Key Guidelines and Compliance Requirements

Typical Capacity Factor Values

| Power Source | Typical Capacity Factor (%) |

|---|---|

| Coal Power Plant | 60 – 80 |

| Natural Gas Plant | 40 – 60 |

| Nuclear Power Plant | 85 – 95 |

| Hydro Power Plant | 30 – 50 |

| Wind Farm | 20 – 45 |

| Solar Power Plant | 15 – 30 |

The capacity factor varies based on the type of power source, plant design, maintenance schedules, and resource availability.

What is Load Factor

Load factor represents the ratio of average load to peak load during a given period. It measures how effectively the electrical power demand is spread over time. In simple terms, it shows how consistently power is being used compared to the maximum demand.

A higher load factor indicates steady energy consumption, while a low load factor shows irregular or fluctuating energy use. Utilities prefer a high load factor because it ensures better utilization of generation and transmission capacity.

Formula for Load Factor

Load Factor = (Average Load) / (Peak Load)

Example of Load Factor

If an industrial plant has an average load of 40 MW and a peak load of 80 MW during a day, the load factor will be:

Load Factor = 40 / 80 = 0.5 or 50%

This means that on average, the plant used half of its maximum load during the day.

Typical Load Factor Values

| Type of Consumer | Typical Load Factor (%) |

|---|---|

| Residential Area | 30 – 50 |

| Commercial Building | 40 – 70 |

| Industrial Consumer | 60 – 90 |

| Data Centers | 70 – 95 |

A high load factor indicates efficient energy use and reduced cost per unit of electricity.

Use our online tool Creepage Distance Calculator – Calculate Safe Insulation & Clearance for PCB and High Voltage Design

Capacity Factor vs Load Factor

The terms capacity factor and load factor are closely related but apply to different perspectives of energy utilization. The capacity factor relates to the generation side, while the load factor relates to the consumption side.

Key Differences Between Capacity Factor and Load Factor

| Parameter | Capacity Factor | Load Factor |

|---|---|---|

| Definition | Ratio of actual energy produced to maximum possible energy | Ratio of average load to peak load |

| Perspective | Power generation performance | Power consumption efficiency |

| Application | Used for power plants | Used for energy consumers or utilities |

| Formula | Actual output / Maximum possible output | Average load / Peak load |

| Ideal Value | Close to 1 (100%) for efficient generation | Close to 1 (100%) for steady demand |

| Typical Range | 20%–95% depending on source | 30%–95% depending on consumer type |

| Example | Wind plant running 25% of time at full load | Factory with 50% average vs peak usage |

| Influenced By | Plant downtime, resource availability | Demand pattern, load variation |

From this comparison, it becomes clear that capacity factor vs load factor focuses on different stages of the energy system—generation and utilization.

Relationship Between Capacity Factor and Load Factor

Although different, the two are indirectly related. A stable and consistent demand pattern (high load factor) allows power plants to run continuously, improving their capacity factor. Conversely, erratic demand (low load factor) causes frequent ramping up and down of generation units, reducing the overall capacity factor.

For example, if a region has a high industrial load that operates around the clock, its load factor will be high, and the power plants supplying that load will also show a higher capacity factor.

Why Capacity Factor and Load Factor Matter

Both factors are crucial for optimizing energy systems, planning infrastructure, and reducing costs.

For utilities:

They help in understanding demand patterns, optimizing generation schedules, and planning maintenance.

For investors:

Capacity factor provides insights into how efficiently renewable plants like wind or solar are performing, which affects profitability.

For consumers:

Load factor indicates how efficiently they are using electricity. A higher load factor reduces the average cost per unit because the fixed demand charges are spread across more consistent usage.

Use our online tool Electricity Load Calculator (kVA) According to IEC and NEC

Example Comparing Capacity Factor vs Load Factor

Let’s take an example of a small industrial region powered by a 50 MW hydroelectric plant.

- The hydro plant generates 200,000 MWh per year.

- The maximum possible generation = 50 MW × 24 × 365 = 438,000 MWh.

- Capacity Factor = 200,000 / 438,000 = 45.6%

Now, the industrial consumers in that region have:

- Average Load = 30 MW

- Peak Load = 45 MW

- Load Factor = 30 / 45 = 66.7%

Here, we can see that while the power plant operates with a moderate capacity factor due to water availability and maintenance, the consumers have a good load factor, indicating steady power use.

Improving Capacity Factor

Power plants can improve their capacity factor through better maintenance, resource forecasting, and technology upgrades. For example, hybrid solar-wind systems can improve utilization since one source can operate when the other is unavailable.

Energy storage also plays a major role. Battery systems help maintain generation even during periods when renewable resources are low, thereby improving the capacity factor.

Improving Load Factor

Consumers can enhance their load factor by distributing their energy use more evenly. Shifting some energy-intensive operations to off-peak hours reduces peaks and increases the average load.

For instance, an industrial plant can schedule heavy machinery use during night hours to balance overall consumption. Smart meters and automated demand management systems also help in monitoring and improving load factor.

Use our online tool Street Light Voltage Drop Calculator – Accurate Cable Sizing & Power Loss Estimation Tool

Impact on Electricity Tariffs

Load factor directly influences electricity pricing. Utilities often charge demand-based tariffs, where customers with low load factors pay higher per-unit rates because their irregular demand puts stress on the grid. On the other hand, consumers with high load factors use energy more consistently and efficiently, leading to lower tariffs.

Importance in Renewable Energy Systems

In renewable energy, the capacity factor vs load factor comparison is especially important. Solar and wind systems have variable output depending on sunlight and wind conditions. While load factor depends on how consumers use electricity, the capacity factor determines how efficiently renewable sources convert natural energy into electricity.

For example, a solar plant in a desert region may achieve a 30% capacity factor due to strong sunlight, while a similar plant in a cloudy region may only achieve 18%. Understanding this helps in selecting the best locations and sizing systems properly.

Final Thoughts on Capacity Factor vs Load Factor

In the debate of capacity factor vs load factor, both are crucial indicators of performance and efficiency. The capacity factor reflects how effectively a power plant generates energy, while the load factor reveals how efficiently energy is consumed.

A high capacity factor means a power source is reliable and consistently generating electricity. A high load factor means energy consumers are using power evenly and efficiently. Both contribute to a stable, cost-effective, and sustainable energy system.

Use our online tool Transformer Efficiency Calculator – Calculate Power, Losses & Performance Instantly

When engineers, investors, or policymakers analyze energy systems, understanding capacity factor vs load factor helps make better decisions for infrastructure planning, cost optimization, and energy sustainability.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#CapacityFactor, #LoadFactor, #EnergyEfficiency, #PowerSystemAnalysis, #ElectricalEngineering, #PowerGeneration, #LoadManagement, #EnergyCalculation, #RenewableEnergy, #EnergyPerformance, #PowerFactor, #ElectricUtility, #GridOptimization, #EngineeringEducation, #EnergyProduction

Thank you, I’ve recently been searching for information about this topic for ages and yours is the greatest I have discovered till now. But, what about the bottom line? Are you sure about the source?