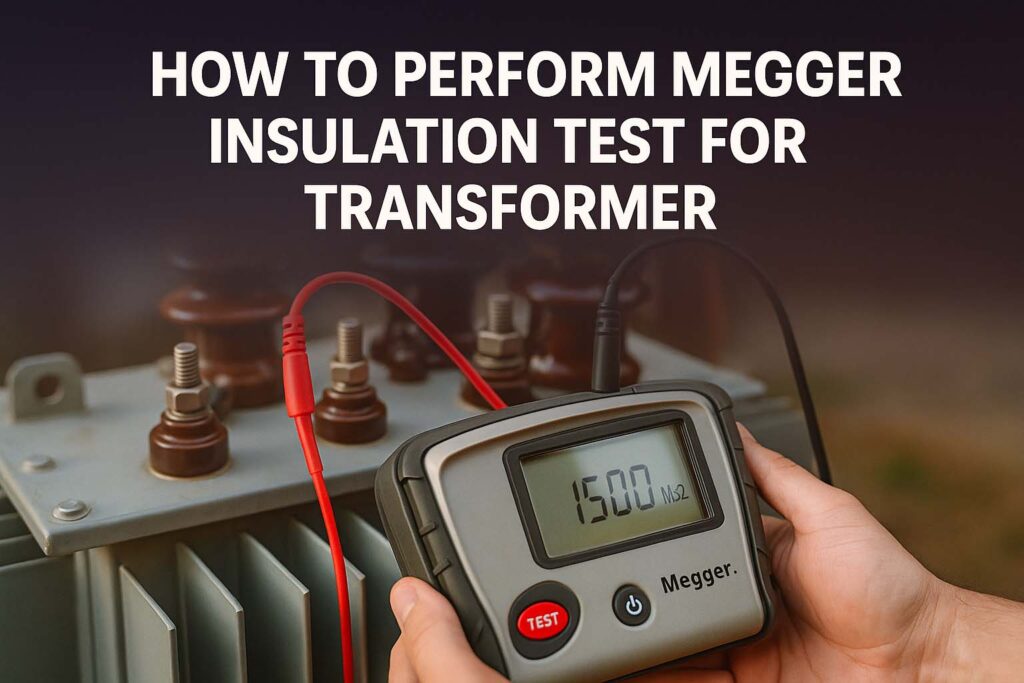

How to Perform Megger Insulation Test for Transformer

Performing a megger insulation test for transformer is one of the most critical maintenance tasks in the electrical industry. It helps assess the health of transformer insulation and ensures long-term reliability. A failed insulation system can lead to transformer breakdown, unplanned outages, or even fire hazards. That’s why understanding this test is essential for every electrical technician and engineer.

What Is a Megger Insulation Test for Transformer?

A megger insulation test checks the resistance offered by transformer insulation against leakage current. The test uses a high-voltage DC source, typically ranging from 500V to 5000V, to measure insulation resistance in mega-ohms. It evaluates how effectively the insulation resists the flow of current between windings, core, and earth.

Insulation resistance is a key indicator of transformer health. A higher resistance value means better insulation condition, while a lower value can point toward aging, moisture, contamination, or physical damage.

Know more about How to Use Megger BM5200 Insulation Tester 5kV

Why Perform Megger Insulation Test for Transformer?

Transformers are exposed to humidity, temperature fluctuations, electrical stress, and aging. All these factors degrade insulation over time. The megger insulation test for transformer helps in:

- Detecting moisture or contamination inside the windings

- Identifying early signs of insulation failure

- Avoiding transformer breakdown and ensuring safety

- Planning preventive maintenance

- Complying with international standards such as IEEE, IEC, and NETA

Regular testing can help prolong the transformer’s service life and reduce costly downtime.

Safety Precautions Before Insulation Testing

Before performing a megger test, safety must be the top priority. Follow these important steps:

- De-energize the transformer completely

- Discharge all windings using a grounding stick

- Disconnect external cables, bushings, and lightning arresters

- Isolate windings to avoid mutual interference

- Wear PPE (Personal Protective Equipment) such as rubber gloves and safety goggles

- Display warning signs around the test area

Remember, the test involves high voltage. Even though it’s DC, it can still cause shock or damage equipment if not handled properly.

Know more about What is Difference Between Megger and Insulation Tester

Megger Insulation Test for Transformer: Step-by-Step Process

Let’s break down the insulation resistance testing process for power and distribution transformers. This method applies to both dry-type and oil-immersed transformers.

1. Identify Test Points

You need to test insulation between various components:

- HV winding to LV winding

- HV winding to earth

- LV winding to earth

- HV to core

- LV to core

For three-phase transformers, test each phase separately.

2. Select the Right Test Voltage

Use the following guideline for selecting test voltage:

| Transformer Rated Voltage | Recommended Megger Voltage |

|---|---|

| Below 1 kV | 500 V |

| 1 kV to 5 kV | 1000 V to 2500 V |

| Above 5 kV | 5000 V |

Over-voltage may damage insulation. Under-voltage gives inaccurate results. Follow the transformer manufacturer’s instructions if available.

3. Perform the Megger Test

- Connect one terminal of the megger to the component under test (e.g., HV winding)

- Connect the other terminal to the reference point (e.g., LV winding or ground)

- Set the correct voltage and start the test

- Observe the resistance value after 60 seconds (IR 1-minute value)

- Repeat for all combinations

Some advanced insulation testers provide Polarization Index (PI) and Dielectric Absorption Ratio (DAR), which give deeper insights into insulation quality.

4. Record the Results

Make sure to log all test results clearly. Create a table for better comparison:

| Test Points | Test Voltage | IR Value (MΩ) | Acceptance Criteria |

|---|---|---|---|

| HV to LV | 5000 V | 2000 MΩ | >1000 MΩ |

| HV to Earth | 5000 V | 1500 MΩ | >1000 MΩ |

| LV to Earth | 1000 V | 800 MΩ | >500 MΩ |

Always compare values with the previous test records. A sudden drop may indicate moisture ingress or insulation damage.

Know more about Best Megger Insulation Tester 10kV

Understanding Test Readings

High IR Values

- Dry and clean insulation

- No moisture

- No contamination

- Safe to operate

Low IR Values

- Presence of moisture

- Dust, oil, or carbon tracking

- Thermal or mechanical aging

- Internal winding fault

If the values are borderline or very low, do not energize the transformer. Dry-out procedures or further diagnostic tests such as Doble testing or tan-delta tests may be required.

Factors Affecting Insulation Resistance

Several environmental and physical conditions can affect the test result:

- Temperature: Higher temperature reduces IR values. Correct readings to 20°C using standard correction factors.

- Humidity: Moist air can absorb into insulation and lower IR readings.

- Contamination: Dust, oil, or salt can create leakage paths.

- Aging: Old transformers naturally show lower resistance.

When in doubt, compare results over time rather than relying on one-time testing.

Know more about How to Use Megger Insulation Tester 5000V

How Often Should You Perform the Test?

The megger insulation test for transformer should be performed during:

- Commissioning

- Annual maintenance shutdowns

- After heavy rainfall or flood exposure

- After major electrical faults

- Before and after transformer oil filtration

Routine testing helps create a baseline and identify trends.

Benefits of Megger Insulation Testing

- Simple and quick to perform

- No need to dismantle transformer

- Non-destructive testing

- Increases transformer reliability

- Ensures compliance with safety standards

- Saves costs by preventing unplanned outages

This test is one of the best diagnostic tools for preventive maintenance in electrical substations and industrial systems.

Polarization Index (PI) and Its Role

If your megger supports timed testing, calculate the PI value using:

PI = IR value at 10 minutes / IR value at 1 minute

| PI Value | Insulation Condition |

|---|---|

| <1 | Very poor – dangerous |

| 1 – 1.5 | Questionable – caution |

| 1.5 – 2 | Fair – aging insulation |

| >2 | Good – insulation is dry |

A good PI value (>2) indicates healthy insulation and no significant moisture content.

Know more about Protection Schemes for Alternator

Limitations of the Test

While useful, the megger insulation test for transformer has some limitations:

- Cannot pinpoint exact fault location

- Affected by environmental conditions

- Cannot differentiate between different failure mechanisms

- Not sufficient for complete insulation diagnostics

For a complete insulation health report, combine this test with other advanced techniques like tan-delta, SFRA, and partial discharge testing.

Conclusion

Performing a megger insulation test for transformer is essential for ensuring transformer reliability, safety, and long life. This test is simple, effective, and provides valuable insights into the health of insulation systems. Regular testing helps in identifying problems early, allowing for timely maintenance or corrective actions.

By understanding the principles, procedures, safety precautions, and interpreting results accurately, electrical engineers can avoid serious transformer failures. Whether it’s a distribution transformer at a factory or a high-voltage unit at a power plant, this test remains a cornerstone of preventive maintenance.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#MeggerTest, #InsulationTesting, #TransformerTesting, #ElectricalMaintenance, #MeggerInsulationTest, #TransformerSafety, #ElectricalTesting, #PreventiveMaintenance, #HVTesting, #ElectricalInspection, #PowerTransformer, #TestAndMeasurement, #ElectricalEngineering, #SubstationMaintenance, #IndustrialElectrical