Demand Factor as Per NEC: Important Guide

Understanding the demand factor as per NEC is essential for electrical engineers, contractors, and professionals in the electrical industry. This concept plays a pivotal role in ensuring proper electrical system design and load calculations, helping to optimize energy use while meeting safety standards.

Table of Contents

What is Demand Factor?

The demand factor is a ratio used to compare the maximum demand of a system to its total connected load. It reflects the average usage of electrical power relative to the maximum power capacity that could potentially be drawn by all connected devices. In the context of the National Electrical Code (NEC), this factor is used to calculate the anticipated demand for electrical systems in residential, commercial, and industrial settings.

Use our online tool Lighting Load Calculation per Square Foot: Download Excel Sheet

The formula for demand factor is simple:

The demand factor allows designers to determine the electrical infrastructure required to safely handle the expected load without over-sizing the system, ensuring cost-effective operations.

Demand Factor as Per NEC: Key Insights

NEC Code Requirements for Demand Factor

The NEC provides guidelines for determining the demand factor in various types of installations. It helps ensure that electrical systems are designed to meet the demands of typical usage while avoiding excessive overestimation of required power, which can lead to unnecessary equipment costs.

According to the NEC, the demand factor varies depending on the type of system and load classification. For example:

- In residential systems, the demand factor typically considers appliances and lighting, often assuming a lower usage compared to total connected load.

- In commercial settings, the demand factor can be higher due to the greater diversity of electrical usage patterns.

In residential areas, NEC often recommends the use of a demand factor of 0.8 to 1.0 for general lighting and receptacles, which assumes that not all devices will operate simultaneously at full capacity.

Know more about nec article 220

Factors Affecting Demand Factor

Several variables can affect the demand factor, making it necessary to account for them when designing electrical systems. These include:

- Load Diversity: Not all devices run simultaneously. For example, in a home, not all lights, appliances, and electronics will be on at the same time.

- Usage Patterns: In commercial spaces, peak demand may vary by time of day, with higher loads during business hours and lower loads during off-hours.

- System Design: The way the electrical system is laid out, including factors like circuit length, breaker sizes, and the capacity of the distribution panel, can influence the demand factor.

Why Demand Factor Matters

The demand factor helps electrical engineers design systems that can handle peak usage without wasting resources. By considering this factor, engineers can reduce the overall size of electrical systems, potentially saving on installation and operating costs. It also helps prevent overloading of circuits, enhancing safety.

How to Calculate Demand Factor According to NEC

Residential Installations

For residential buildings, the NEC suggests specific guidelines for determining the demand factor. Typically, for a residential unit with a connected load of 10,000 watts, the demand factor might be calculated as follows:

- Total Connected Load: 10,000 watts

- Maximum Demand: 8,000 watts (estimated average use)

Thus, the demand factor would be:

Commercial Installations

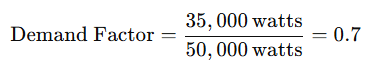

In commercial spaces, the demand factor might differ significantly due to the greater diversity in load types and usage schedules. For a restaurant, the total connected load might be 50,000 watts, but the actual demand during peak hours may only be 35,000 watts, leading to a demand factor of:

Industrial Installations

For industrial settings, where high-powered machinery and specialized equipment are used, the demand factor is typically higher due to the need for equipment to operate at full capacity during peak production hours. For example, if the total connected load in a factory is 200,000 watts, but the maximum demand is 150,000 watts, the demand factor would be:

Explore everything about Load Calculation for Commercial Building: Pro Guide to Accurate Sizing & Cost-Smart Design

Related NEC Standards for Demand Factor

Several standards in the NEC refer to demand factors, offering further guidance on proper calculation and application. These include:

- NEC Article 220: This section provides a detailed breakdown of load calculations and demand factors for various types of installations. It’s particularly useful when designing residential and commercial electrical systems.

- NEC Article 310: This article addresses conductors and the need for sizing based on demand calculations. It emphasizes that wiring should be sized not just for the connected load but also according to expected demand.

- NEC Article 400: This section touches on the use of flexible cords and cables in systems where the demand factor can fluctuate due to mobility or temporary installations.

These articles offer detailed tables and formulas, ensuring that professionals follow standardized procedures for accurate load calculations, which help in maintaining electrical safety and system efficiency.

Use our online tool EV Charger Load Calculation: A Comprehensive Guide

Practical Applications of Demand Factor in Design

Electrical engineers use demand factor to optimize the design of circuits and electrical panels. Here’s how demand factor plays a role:

- Overcurrent Protection: Properly calculated demand factors help ensure that circuit breakers and fuses are properly rated for expected peak loads without risking unnecessary tripping or overheating.

- Transformer Sizing: Demand factors guide the sizing of transformers, helping engineers to avoid over-sizing transformers, which can result in higher capital costs and inefficiency.

- Panel and Distribution Sizing: By using demand factor calculations, the size of electrical panels and distribution boards can be optimized, ensuring efficient power delivery without overspending on capacity.

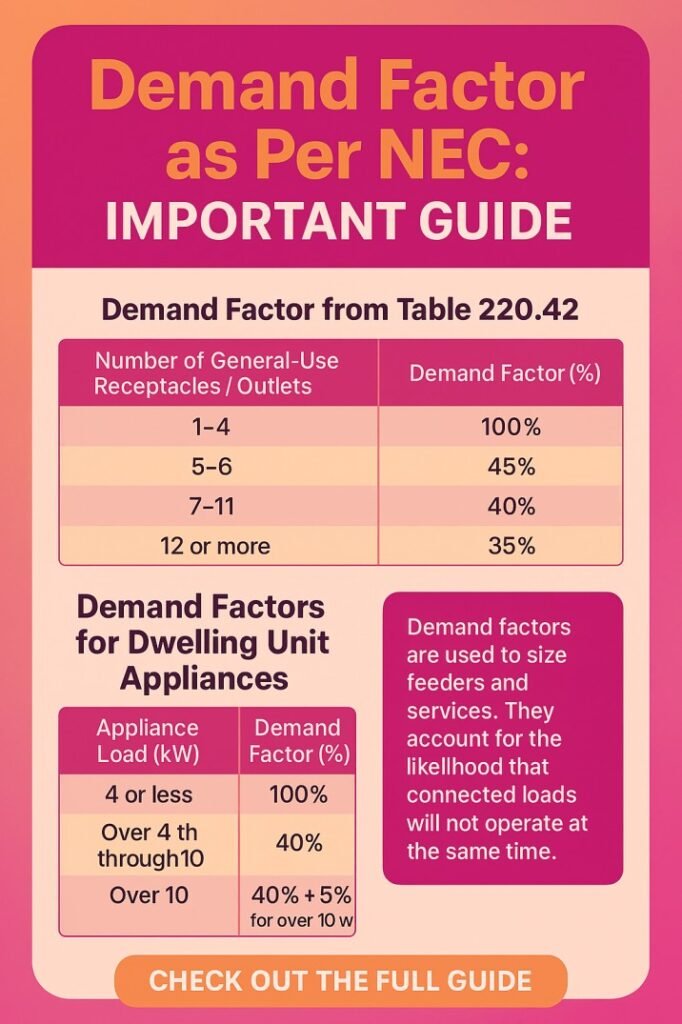

Demand Factor Table

The following table provides typical demand factors for various types of installations, based on NEC guidelines.

| Type of Installation | Demand Factor Range |

|---|---|

| Residential (General Use) | 0.8 – 1.0 |

| Commercial (Lighting) | 0.6 – 0.8 |

| Commercial (Mixed Use) | 0.7 – 0.9 |

| Industrial (Heavy Load) | 0.75 – 0.85 |

Use our online tool Electrical Panel Heat Load Calculation: Best Guide

Conclusion

Understanding demand factor as per NEC is a critical part of electrical design. It helps engineers create efficient, safe, and cost-effective systems that are sized according to actual usage patterns rather than theoretical maximums. By following NEC guidelines, electrical systems are better equipped to handle real-world loads, which reduces the risk of overloads and minimizes unnecessary expenses.

For electrical professionals, calculating and applying the demand factor correctly is not just a matter of code compliance but a vital part of ensuring the safety and longevity of the electrical systems they design.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#DemandFactor, #NECStandards, #ElectricalEngineering, #EnergyManagement, #LoadCalculations, #PowerDemand, #NECRegulations, #ElectricalSystems, #ElectricalCode, #EnergyEfficiency, #DemandFactorNEC, #PowerConsumption, #ElectricalDesign, #NECCompliance, #EnergyOptimization