AC to DC Converter 24V Output: A Comprehensive Guide

AC to DC Converter 24V

An AC to DC Converter 24V Output is a critical component in many electrical and electronic systems. These converters play a central role in transforming alternating current (AC) from power grids into a stable 24-volt direct current (DC) supply. This output is commonly used in industrial automation, battery charging, electric vehicles, and embedded systems.

Table of Contents

Table of Contents

In this article, we’ll explore how these converters work, the types available, and key selection criteria. We’ll also compare them with other voltage-level converters and provide technical insights to help you choose the right product for your application.

What Is an AC to DC Converter 24V?

An AC to DC Converter 24V is a power electronic device that converts high-voltage AC (usually 120V or 230V) to a regulated 24V DC output. The 24V DC is ideal for powering sensors, actuators, microcontrollers, and control circuits in industrial and commercial setups.

This conversion process usually involves three main stages: rectification, filtering, and regulation. The rectifier changes AC to unregulated DC, filters remove unwanted ripples, and voltage regulators provide a clean, steady 24V output.

Why 24V DC Is Widely Used

Many industries prefer 24V DC for control systems and automation. It’s considered safe, easy to distribute across large areas, and efficient for low-power devices. Here are some benefits:

- Safety: 24V DC is less hazardous compared to higher voltages.

- Standardization: Many PLCs and relays are designed for 24V DC input.

- Compatibility: Compatible with a wide range of sensors, timers, and control units.

Know more about Variable Frequency Drive Interview Questions

How AC to DC Converter 24V Output Works

The working of an AC to DC Converter 24V Output can be broken down into several stages:

Rectification Stage

The incoming AC signal is first passed through a rectifier, usually a bridge rectifier. This stage converts AC (alternating) into pulsating DC.

Filtering Stage

After rectification, the DC output still contains ripples. A capacitor filter is used to smoothen the output. This results in a more stable DC signal but may still need further regulation.

Regulation Stage

To maintain a constant 24V output regardless of input fluctuations or load variations, voltage regulators (linear or switching) are employed.

Know more about Motor Overload Setting Table

Types of AC to DC Converter 24V Output

Different applications call for different types of converters. Below are some of the most common types.

| Type | Description |

|---|---|

| Linear Power Supply | Simple and reliable. Best for low-power, low-noise applications. |

| Switching Power Supply | Efficient and compact. Ideal for higher current loads and industrial use. |

| DIN Rail Mounted | Designed for industrial panels. Easy to install and maintain. |

| Enclosed Power Supply | Offers protection from dust and moisture. Suitable for factory environments |

| Waterproof Power Supply | Designed for outdoor use. Fully sealed against water ingress. |

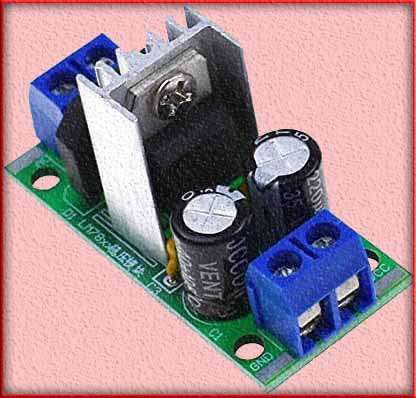

Components of AC to DC Converter 24V Output

Step-Down Transformer: The conversion process begins with a step-down transformer that reduces the high voltage of the AC mains to a lower voltage level. For a 24V output, the transformer steps down the voltage from the mains, which is typically 110V or 220V depending on the region.

Rectifier Diodes: After the transformer, rectifier diodes are used to convert the alternating current to pulsating direct current. The rectification process results in a pulsating waveform that still contains both positive and negative voltage swings.

Filter Capacitor: A filter capacitor is added after the rectifier diodes to smooth out the pulsating DC waveform. The capacitor charges during the positive half-cycles and discharges during the negative half-cycles, reducing the ripple and creating a relatively stable DC voltage.

Know more about Backup Generator Sizing Calculator

Voltage Regulator: To ensure a constant and accurate 24V output, a voltage regulator is employed. The voltage regulator maintains a consistent output voltage despite fluctuations in the input voltage or load conditions, providing a reliable 24V output.

Heat Sink: Since power conversion can generate heat, especially in voltage regulators, a heat sink is often added to dissipate the excess heat and maintain the converter’s efficiency and reliability.

Wiring Details of AC to DC Converter

Input Wiring: The AC input wiring is connected to the primary side of the step-down transformer. The voltage level will depend on the mains voltage in the specific region.

Output Wiring: The output wiring is connected to the secondary side of the transformer, where the stepped-down voltage is obtained. This lower voltage is then rectified, filtered, and regulated to achieve a stable 24V DC output.

Filter Capacitor Wiring: The filter capacitor is connected in parallel to the output of the rectifier diodes to smooth out the DC voltage.

Know more about Demand Factor as Per NEC

Voltage Regulator Wiring: The voltage regulator is connected to the output of the filter capacitor to provide the desired 24V DC output.

Installing an AC to DC Converter 24V Output requires careful wiring:

- Use appropriate gauge wires based on current rating

- Keep AC and DC wiring separate to avoid electromagnetic interference

- Use fuses or breakers for added protection

- Ensure grounding of the converter chassis to prevent electric shock

For solar pump systems or EV charging installations, good AC cable management is also crucial. Refer to our AC cable arrangement for solar tubewell systems for detailed guidelines.

Applications of AC to DC Converter 24V Output

The 24V DC supply is ubiquitous in modern electrical systems. Some common applications include:

- Industrial automation: For PLCs, sensors, and actuators

- Battery charging: Especially for lead-acid and Li-ion batteries

- LED lighting systems: Many industrial and commercial LED lights require 24V DC

- Electric vehicles: Subsystems often require stable 24V supplies

- Control panels: The backbone of process control and instrumentation

How to Choose the Right AC to DC Converter 24V Output

When selecting a converter, consider the following factors:

Input Voltage Range

Make sure the input voltage range covers your AC supply. Most commercial converters accept 85–265V AC input to support global voltage standards.

Output Current and Power Rating

Determine the total current requirement of all devices connected to the converter. For example, if your load requires 5A, you’ll need a 120W (24V x 5A) converter at minimum.

Efficiency

Higher efficiency means less heat and lower energy bills. Look for converters with at least 85% efficiency for industrial applications.

Safety and Certifications

Ensure the converter meets standards like IEC, CE, and UL for electrical safety and electromagnetic compatibility.

Operating Environment

If your setup is in a harsh or outdoor environment, go for enclosed or waterproof models. Otherwise, a standard panel-mounted unit may suffice.

Protections

Look for overvoltage, overload, short-circuit, and over-temperature protections. These features increase the reliability and safety of the system.

Technical Parameters to Consider

Below is a table of essential technical parameters that help evaluate an AC to DC Converter 24V Output:

| Parameter | Typical Range / Value |

|---|---|

| Input Voltage | 85V – 265V AC |

| Output Voltage | 24V DC (regulated ±1%) |

| Output Current | 0.5A to 20A (based on model) |

| Efficiency | 85% – 95% |

| Ripple & Noise | < 150mVp-p |

| Operating Temperature | -10°C to +60°C |

| Protection Features | OVP, OCP, SCP, OTP |

| Mounting Type | Wall, DIN Rail, Enclosure |

Troubleshooting Common Issues

Even the best converters can run into issues. Here are a few tips:

- No Output: Check for blown input fuse or incorrect AC supply

- Low Voltage Output: Ensure the load is within rated current

- Overheating: Improve ventilation or reduce load current

- Frequent shutdowns: Verify if protection circuits are triggered

Long-Term Maintenance Tips

To ensure your AC to DC Converter 24V Output lasts longer:

- Clean dust regularly if used in a dusty environment

- Check terminal connections annually to prevent loose contacts

- Monitor output voltage for signs of wear or component aging

For transformers and protection settings, see our guide on Differential Relay Setting Calculation for Transformer.

Conclusion

An AC to DC Converter 24V Output is essential for many control and automation systems. From understanding the working principle to selecting the right type, each step ensures safe and efficient power delivery. Whether you’re an engineer setting up a control panel or a technician working on EV chargers, knowing the key aspects of 24V DC converters will help you make informed decisions.

Always choose high-quality, certified devices, and make sure to factor in load, environment, and long-term reliability. A properly selected and installed converter not only boosts system performance but also ensures operational safety.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#acdcconverter, #24voutput, #powerconverter, #dcpowersupply, #24vdc, #rectifiercircuit, #electronicsprojects, #powersupplydesign, #electricalengineering, #voltageregulator, #smps, #convertercircuit, #dcconverter, #electronicscomponents, #engineeringtutorial

Thanks for finally talking about > AC To DC Converter 24V Output: A

Comprehensive Guide : Electrical Hub < Loved it!