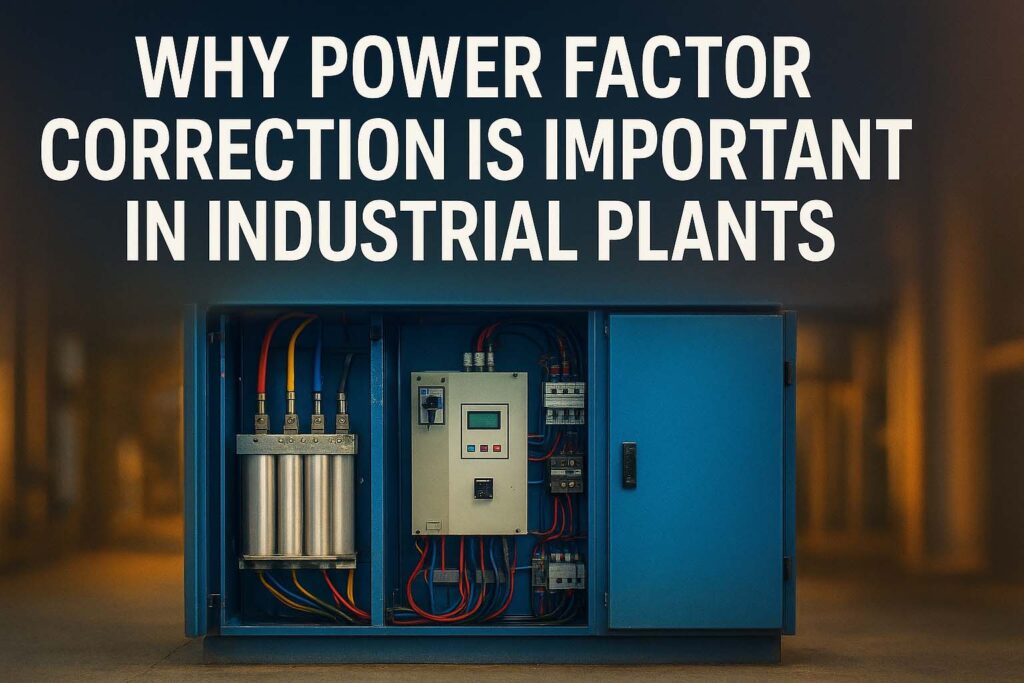

Why Power Factor Correction is Important in Industrial Plants

In every industrial plant, efficiency is not just about the machines or the workforce. It is also about how effectively electrical power is used. One of the most overlooked aspects of energy efficiency is power factor correction. Many plant managers are aware of high energy bills, transformer heating, and penalties from utility companies but do not always connect these issues with low power factor. If you want to measure the effect of improving your system, you can try our Power Factor Correction Calculator which helps estimate the required capacitor bank size for your plant.

Table of Contents

Table of Contents

Understanding why power factor correction is important in industrial plants goes far beyond avoiding penalties. It is about reducing energy losses, improving the lifespan of electrical equipment, and ensuring stable system operation. A high power factor means the electrical system is operating close to its maximum efficiency, while a low power factor signals waste, unnecessary strain, and hidden costs.

Industrial plants often use large motors, welding machines, induction furnaces, and compressors. These are inductive loads that consume reactive power. When reactive power is high, the power factor drops, and this reduces the real usable power available. The result is higher current demand for the same useful power, which stresses cables, switchgear, and transformers. This is why industries are encouraged and sometimes forced by utilities to maintain a minimum power factor, usually above 0.9.

Key Takeaways

- Power factor correction improves energy efficiency, reduces losses, and prevents penalties.

- Industrial loads like motors and furnaces lower power factor due to reactive power.

- Correcting power factor reduces electricity costs and improves equipment lifespan.

- A reliable way to calculate savings is by using a Power Factor Correction Calculator.

Why Power Factor Correction is Important in Industrial Plants

Power factor correction is not just a compliance measure. It is a strategic approach to energy management. When the power factor is low, the system draws more current than necessary. This extra current does not contribute to useful work but still heats up conductors, increases copper losses, and reduces the effective capacity of transformers. By installing capacitor banks or automatic power factor correction panels, the reactive power is balanced and the system returns closer to unity power factor.

Use our online tool Power Factor Correction Capacitor Calculator

For example, consider a 1,000 kW motor load operating at 0.7 power factor. The apparent power drawn from the grid is:

| Parameter | Value |

|---|---|

| Real Power (kW) | 1000 |

| Power Factor | 0.7 |

| Apparent Power (kVA) | 1428 |

| Reactive Power (kVAR) | 1020 |

If this power factor is corrected to 0.95, the apparent power reduces significantly:

| Parameter | Value |

|---|---|

| Real Power (kW) | 1000 |

| Power Factor | 0.95 |

| Apparent Power (kVA) | 1053 |

| Reactive Power (kVAR) | 328 |

This simple calculation shows how much reactive power is reduced. The current drawn from the grid drops by more than 25%, which reduces system stress and utility bills.

Technical Insights into Why Power Factor Correction is Important in Industrial Plants

Electrical systems are designed for both real power (kW) and reactive power (kVAR). Real power performs useful work like turning motors or running lights. Reactive power sustains the magnetic fields required by motors, transformers, and inductors. While reactive power is essential, it does not produce useful work, yet it still occupies system capacity.

The efficiency of power utilization is expressed as Power Factor (PF):

Power Factor = Real Power (kW) ÷ Apparent Power (kVA)

A low power factor indicates high reactive power. This leads to:

- Higher line currents

- Overloaded transformers

- Increased I²R losses

- Voltage drops at load ends

Correcting power factor means adding capacitors or synchronous condensers that supply leading reactive power, thereby offsetting the lagging reactive demand of motors and inductive loads.

Know more about IEC Standard for Battery Charger

Benefits of Power Factor Correction in Industrial Plants

Reduction in Energy Bills

Utility companies often impose penalties when the average monthly power factor falls below a threshold, commonly 0.9. With correction, industries avoid these penalties and reduce maximum demand charges.

Increased Equipment Life

Cables, switchgear, and transformers last longer when currents are optimized. Heat losses are minimized, and maintenance frequency decreases.

Improved Voltage Stability

Low power factor often leads to voltage drops at load ends, which makes motors run hotter and less efficiently. Power factor correction stabilizes voltage levels and ensures reliable motor performance.

Increased System Capacity

By lowering apparent power demand, existing transformers and distribution equipment can handle more load without upgrades. This saves investment costs in capacity expansion.

Why Power Factor Correction is Important in Industrial Plants for Energy Management

Industrial energy management is not only about reducing consumption but also about improving quality. Power factor correction is a key pillar of energy management because it directly addresses wasteful reactive power. When plants invest in automatic power factor correction panels, the system adjusts dynamically to load variations. This ensures consistent efficiency across different operating conditions.

Know more about Top Electrical Engineering Software: AutoCAD, ETAP, MATLAB Reviewed

For industries with heavy inductive loads, such as steel mills, textile factories, or chemical plants, even a 5% improvement in power factor can translate into thousands of dollars saved annually.

Challenges in Implementing Power Factor Correction

While the benefits are clear, there are challenges too. Choosing the correct capacitor size, protecting against harmonic resonance, and ensuring proper placement are essential. Incorrect correction may lead to over-compensation, where the power factor becomes leading, causing instability. This is why engineers use tools like a Power Factor Correction Calculator before finalizing the capacitor bank rating.

Practical Example

Suppose an industrial plant runs 2000 kW of load at 0.75 power factor. Without correction, the apparent power is 2667 kVA, drawing 3860 A at 400 V. After correction to 0.95 power factor, apparent power drops to 2105 kVA, and current reduces to 3040 A. This 820 A reduction saves conductor losses, reduces transformer heating, and lowers electricity demand charges.

| Case | Load (kW) | Power Factor | Apparent Power (kVA) | Current (A) |

|---|---|---|---|---|

| Before Correction | 2000 | 0.75 | 2667 | 3860 |

| After Correction | 2000 | 0.95 | 2105 | 3040 |

This shows the tangible savings and technical relief that power factor correction provides.

Know more about Earth Ground Testing: Clamp Meter vs Fall-of-Potential Method

Conclusion

Now that we understand why power factor correction is important in industrial plants, it is clear that it is not only about compliance but also about efficiency, savings, and sustainability. By reducing reactive power, industries optimize their electrical systems, extend equipment life, and avoid penalties. With the increasing cost of energy, power factor correction has become a vital part of industrial energy strategies.

If you are planning to improve your plant’s efficiency, start by measuring and calculating your requirement using a Power Factor Correction Calculator. This will give you the exact capacitor bank size needed to correct your system and maximize savings.

Know more about Off-Grid Solar System Design Guide for Remote Areas

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#PowerFactorCorrection, #IndustrialEnergy, #EnergyEfficiency, #IndustrialPlants, #ElectricalEngineering, #PowerQuality, #ReduceEnergyBills, #IndustrialMaintenance, #EnergyManagement, #ElectricalSystems, #EnergySavings, #IndustrialPower, #ElectricalDesign, #SaveElectricity, #PowerFactor