Star Delta Motor Cable Size Calculator

Understanding how to calculate the cable size for a star delta motor is essential in electrical installations. The star delta starter is widely used to reduce the starting current of motors, especially those above 5 HP or 3.7 kW. Proper cable sizing ensures safety, efficiency, and compliance with electrical standards. This article will guide you through the star delta motor cable size calculator approach, explaining key parameters, methods, and standards to follow.

What is a Star Delta Motor Connection?

A star delta motor connection is a type of reduced voltage starter. It connects the motor in a star configuration during start-up and then shifts to a delta connection for normal operation. This reduces the starting current to about one-third of the direct-on-line starting current.

In a star connection, the voltage per winding is reduced. This lowers the torque but helps minimize the mechanical and electrical stress on equipment. Once the motor reaches about 80% of its speed, it switches to the delta mode for full voltage operation.

Why Cable Sizing is Critical in Star Delta Starters

Choosing the correct cable size is vital. Undersized cables can cause voltage drops, excessive heating, and energy loss. Oversized cables increase cost unnecessarily. A well-calculated cable size ensures proper operation of the motor and protection against overheating.

When calculating cable sizes for a star delta motor cable size calculator, you must consider the wiring of three parts:

- Cable from supply to the starter

- Cable from starter to motor (delta connection)

- Cable from starter to motor (star connection)

Each cable experiences different current loads based on the connection type.

Current Calculation for Star Delta Motors

To use a star delta motor cable size calculator, start with calculating the full load current of the motor. Use the formula:

I (A) = (P × 1000) / (√3 × V × pf × η)

Where:

- P is motor power in kW

- V is line voltage (Volts)

- pf is power factor (typically 0.8)

- η is efficiency (usually between 0.85 to 0.95)

Example for a 15 kW motor at 400V, 0.8 power factor, and 90% efficiency:

I = (15 × 1000) / (1.732 × 400 × 0.8 × 0.9) ≈ 30.06 A

This is the full load current. During star connection, each winding sees only 1/√3 of the line current. So, star current is:

I_star = I / √3 ≈ 17.35 A

This is useful for sizing cables between the starter and the motor during star connection.

How Star Delta Affects Cable Sizing

The cables carry different current loads in different parts:

- Main cable (supply to starter): Carries full line current. Size based on full load.

- Cable between starter and motor delta contactor: Carries full line current.

- Cable between starter and motor star contactor: Carries reduced current (1/√3).

So, the star delta motor cable size calculator uses different sizes depending on connection path.

Cable Size Selection Table (Copper Conductor, PVC Insulated)

| Motor Power (kW) | Full Load Current (A) | Main Cable Size (mm²) | Star Cable Size (mm²) | Delta Cable Size (mm²) |

|---|---|---|---|---|

| 7.5 | 15.2 | 4 | 2.5 | 4 |

| 11 | 22.3 | 6 | 4 | 6 |

| 15 | 30.1 | 10 | 6 | 10 |

| 18.5 | 36.8 | 10 | 6 | 10 |

| 22 | 43.8 | 16 | 10 | 16 |

| 30 | 59.6 | 25 | 16 | 25 |

This table assumes ambient temperature of 30°C, three-core copper cable, 400V system, and 90% motor efficiency.

Voltage Drop in Star Delta Motors

Voltage drop should not exceed 5% of the supply voltage. Excessive voltage drop affects motor performance and life span. To calculate voltage drop:

Vd = √3 × I × L × R

Where:

- I is current in amperes

- L is one-way cable length in meters

- R is resistance in ohms/km (depends on cable size)

Select the cable size to keep voltage drop under 5% of 400V, which is 20V max. Use manufacturer’s data for resistance values.

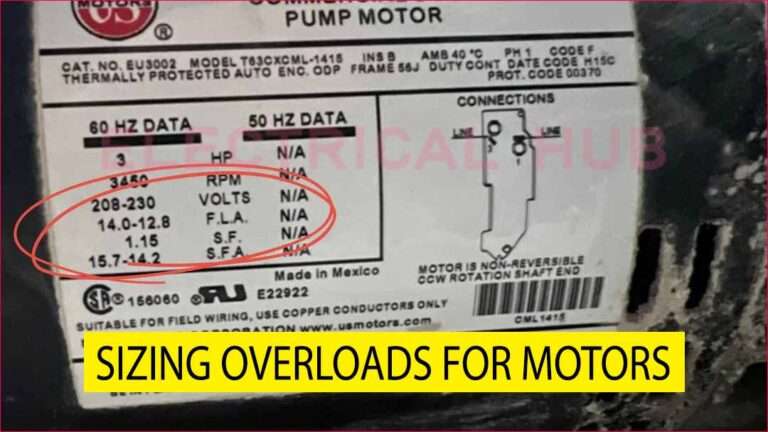

Cable Selection Standards and References

Cable sizing must follow applicable standards. Refer to the following:

- IEC 60228: Conductor sizes and current ratings

- IEC 60364: Electrical installations and protection

- NEC (NFPA 70): National Electrical Code for cable ampacity

- IS 3961: Indian standard for current-carrying capacity

- IEEE 141 (Red Book): Electrical power distribution design

Always check local regulations. Use cable derating factors for ambient temperature, grouping, and soil conditions if underground.

Common Mistakes in Cable Sizing

Incorrect cable sizing is a common issue. Avoid these mistakes:

- Using same size cable for all three legs

- Ignoring voltage drop over long distances

- Skipping derating factors for temperature or grouping

- Using motor nameplate current without calculating actual load

- Forgetting that star-connected cables carry reduced current

A star delta motor cable size calculator prevents such errors by providing accurate, data-driven results.

Practical Example Using a Star Delta Motor Cable Size Calculator

Let’s consider a 22 kW, 400V, 3-phase induction motor.

Given:

- Voltage = 400 V

- Efficiency = 90%

- Power Factor = 0.8

- Cable Length = 30 meters

Step 1: Calculate Full Load Current

I = (22 × 1000) / (1.732 × 400 × 0.8 × 0.9) ≈ 44.3 A

Step 2: Select cable sizes

- Main Cable (from breaker to starter): 16 mm²

- Delta Cable (starter to motor delta contactor): 16 mm²

- Star Cable (starter to motor star contactor): 10 mm²

Check voltage drop using cable resistance values from standards. Ensure total voltage drop < 20V.

Star Delta vs Direct-On-Line Cable Sizing

In DOL starting, the cable from supply to motor carries full inrush current. This may be 6–8 times the full load current. So, the cable size must handle this surge.

In star delta, the inrush current is reduced significantly. Hence, cable heating and stress are minimized. This allows for more optimized cable sizing.

However, the star delta method uses more cables and control devices. So, while it saves energy and stress on cables, it may increase initial setup cost.

Conclusion

The star delta motor cable size calculator is a powerful tool for safe and efficient electrical design. By calculating the correct cable size for each part of the starter, engineers avoid overheating, reduce energy loss, and extend motor life.

Always consider factors such as motor power, distance, voltage drop, and standards like IEC 60364 or NEC guidelines. Use a calculator or formula-based approach to get accurate results. With proper cable sizing, you ensure safe, cost-effective, and compliant motor operation.

References

- IEC 60228: Conductors of Insulated Cables

- IEC 60364: Electrical Installations for Buildings

- NFPA 70: National Electrical Code

- IEEE Std 141: Electric Power Distribution for Industrial Plants

- IS 3961: Recommended current-carrying capacity of cables

- Schneider Electric: Technical Guide on Motor Starters

- ABB Motor Starting Handbook

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#StarDeltaStarter, #MotorCableSize, #CableCalculator, #ElectricalEngineering, #MotorWiring, #ThreePhaseMotor, #CableSizing, #MotorStarter, #PowerDistribution, #IndustrialAutomation, #ElectricalDesign, #MotorControl, #WireSizeCalculator, #StarDeltaConnection, #MotorProtection

Spot on with this write-up, I honestly think this amazing site

needs a lot more attention. I’ll probably be back again to see

more, thanks for the information!

Exceptional post but I was wanting to know if you could write a litte more on this subject?

I’d be very grateful if you could elaborate a little bit more.

Many thanks!

Wow, this paragraph is good, my younger sister is analyzing such things,

therefore I am going to tell her.

Thanks very interesting blog!

For latest news you have to pay a visit the web and on world-wide-web I

found this website as a finest web site for most recent updates.

Keep on writing, great job!

Hi there everyone, it’s my first go to see at this website,

and article is truly fruitful in support of me,

keep up posting these types of content.