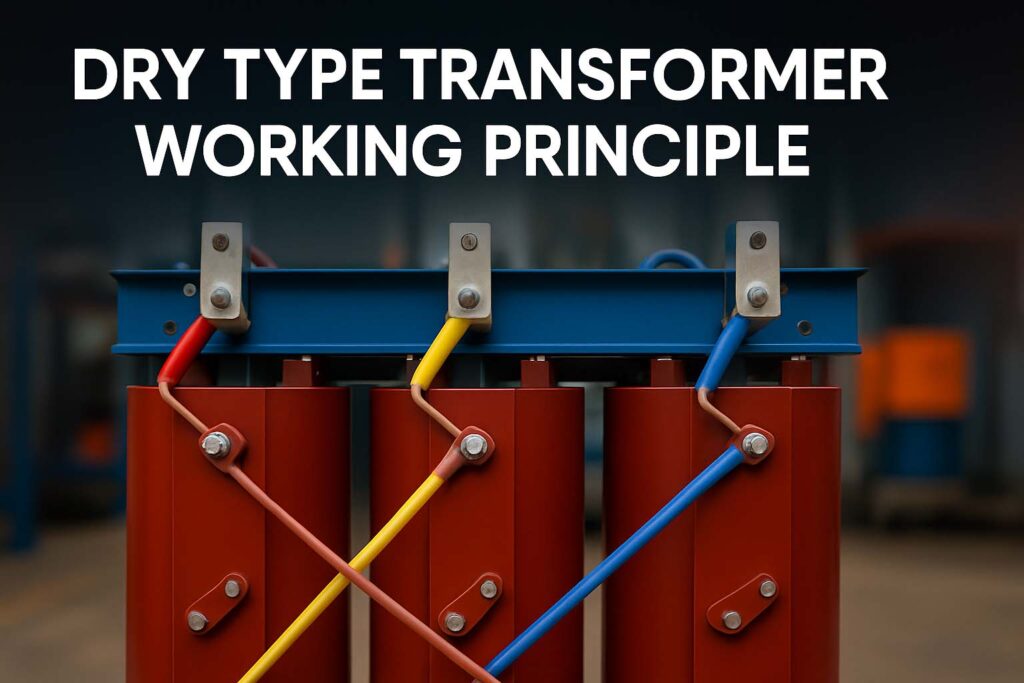

Dry Type Transformer Working Principle

Understanding the Dry Type Transformer Working Principle

The dry type transformer working principle is based on the fundamental laws of electromagnetic induction. Unlike oil-filled transformers, dry type transformers use air instead of insulating oil. This makes them safer and environmentally friendly, especially for indoor applications.

In this article, we will explain how dry type transformers operate, their internal construction, and their technical features. We’ll also explore various types, applications, and performance aspects, helping you understand everything about the dry type transformer working principle.

What Is a Dry Type Transformer?

A dry type transformer is a static electrical device that transfers power from one voltage level to another without any moving parts. It does not use liquid for insulation. Instead, it uses air and epoxy resin to insulate and cool the windings.

Because there is no oil, the risk of fire or leakage is very low. This makes them ideal for places like hospitals, schools, malls, and underground stations.

Know more about Top 15 Dry Type Transformer Manufacturers

Dry Type Transformer Working Principle Explained

At the heart of the dry type transformer working principle is Faraday’s Law of Electromagnetic Induction. It states that when the magnetic field around a conductor changes, a voltage (EMF) is induced in it.

In a transformer, when alternating current (AC) flows through the primary winding, it creates a magnetic field. This magnetic field passes through the laminated iron core and links to the secondary winding. The magnetic flux is constantly changing due to the alternating nature of the supply.

This changing flux induces a voltage in the secondary winding. The voltage level depends on the number of turns in each coil. If the secondary coil has more turns, the voltage increases. If it has fewer turns, the voltage decreases.

Know more about power transformer manufacturers

This is how energy is transferred without any physical connection. Only magnetic coupling is involved.

Construction and Components

To understand the dry type transformer working principle, let’s take a look at its main parts:

- Core: Made of laminated silicon steel, the core provides a low-resistance path for magnetic flux.

- Primary Winding: The coil connected to the input voltage source.

- Secondary Winding: The coil from which output voltage is obtained.

- Insulation Material: Epoxy resin or varnish is used to insulate the windings.

- Cooling System: Air is used as the primary medium for cooling.

Know more about Dry Type Transformer Types

Here is a simple comparison of dry type and oil-filled transformer components:

| Component | Dry Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Cooling Medium | Air or forced air | Mineral oil |

| Insulation | Epoxy resin, varnish | Oil and cellulose paper |

| Maintenance Needs | Low | Moderate to high |

| Fire Risk | Very low | Medium to high |

| Environmental Safety | High | Lower |

Types of Dry Type Transformers

To further understand the dry type transformer working principle, it’s important to look at its main types:

Cast Resin Transformer (CRT): Windings are cast in epoxy resin. They have excellent moisture resistance and are used in harsh environments.

Vacuum Pressure Impregnated (VPI): Windings are impregnated in varnish and cured in a vacuum chamber. They are suitable for indoor applications.

Open Wound Type: Windings are open to air, often with fans for cooling. They are cheaper but more exposed to environmental factors.

Know more about IEC Standard for Dry Type Transformer

Cooling Methods

Dry type transformers use the following cooling techniques:

- AN (Air Natural): Natural convection is used for cooling. It is suitable for low-power applications.

- AF (Air Forced): Fans are used to blow air over the windings for better heat dissipation. This is used in higher capacity transformers.

These cooling methods directly influence the transformer’s efficiency and lifespan.

Efficiency and Performance

Modern dry type transformers are highly efficient. Their efficiency usually ranges from 95% to 98.5%. However, the actual performance depends on factors like core quality, insulation type, and load conditions.

Power losses in dry type transformers can be classified as:

- Core Losses (No-load Losses): Caused by alternating magnetic fields in the core.

- Copper Losses (Load Losses): Caused by resistance in the windings during load flow.

The table below summarizes key performance parameters:

| Parameter | Typical Value |

|---|---|

| Efficiency | 95% to 98.5% |

| Temperature Rise | 80°C to 150°C |

| Operating Frequency | 50 Hz / 60 Hz |

| Noise Level | Low to medium |

| Service Life | 20–30 years with low maintenance |

Advantages of Dry Type Transformers

The dry type transformer working principle offers several advantages:

- Safety: No oil means no fire hazard.

- Low Maintenance: No need for oil checks or leakage control.

- Eco-Friendly: No risk of ground or water contamination.

- Durability: Suitable for humid or dusty environments.

- Compact Design: Ideal for indoor installations.

Know more about IEC Standard for Busbar Clearance

Applications of Dry Type Transformers

Thanks to their safe operation and ease of installation, dry type transformers are widely used in:

- Hospitals and healthcare centers

- High-rise buildings

- Underground metro stations

- Wind and solar power plants

- Marine vessels and ships

- Educational institutions

- Data centers and control rooms

Challenges and Limitations

Despite their benefits, there are some limitations to consider in the dry type transformer working principle:

- Higher Initial Cost: More expensive than oil-filled units of the same rating.

- Lower Overload Capacity: Not suitable for applications with frequent load surges.

- Cooling Limitations: Air cooling is less efficient compared to oil immersion.

Installation Guidelines

For proper functioning and long life, consider these installation factors:

- Ensure proper ventilation in the room.

- Avoid direct exposure to moisture or chemicals.

- Keep clearance around the transformer for air flow.

- Follow local electrical codes and safety standards.

Poor ventilation or overload can cause the windings to overheat, damaging the insulation.

Maintenance Practices

Although dry type transformers are low-maintenance, regular inspections are still necessary. Key maintenance tasks include:

- Visual inspection for cracks or discoloration

- Checking for unusual noise or vibration

- Periodic tightening of terminal connections

- Monitoring ambient and operating temperature

Proper preventive maintenance ensures reliability and extends service life.

Future of Dry Type Transformers

With the rising demand for green energy and urban infrastructure, dry type transformers are seeing wider adoption. Innovations like smart monitoring, advanced insulation materials, and compact designs are improving their performance.

Also, the development of amorphous core technology is reducing no-load losses even further.

Conclusion

The dry type transformer working principle revolves around electromagnetic induction and magnetic coupling between windings. These transformers provide safe, eco-friendly, and efficient power transfer, especially in indoor environments.

Whether you’re an electrical engineer, facility manager, or energy consultant, understanding how dry type transformers work helps you make informed decisions. From hospitals to solar farms, their role in modern power systems continues to grow.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#DryTypeTransformer, #TransformerWorkingPrinciple, #ElectricalEngineering, #PowerDistribution, #DryTypeVsOilType, #EnergySolutions, #TransformerDesign, #ElectricalTransformers, #DryTransformerBasics, #IndustrialPower, #SafePowerSystems, #DryTypeAdvantages, #TransformerEducation, #TechExplained, #EngineeringInsights