NEC Article 440 Explained: HVAC Equipment Rules Most Electricians Miss

NEC Article 440 covers the electrical requirements for air conditioning and refrigeration equipment. Many service calls, inspection failures, and equipment breakdowns trace back to mistakes that fall directly under nec article 440. These rules are different from standard motor or appliance wiring, and that is where many electricians get caught off guard.

Table of Contents

Heating and cooling systems combine motors, compressors, overload protection, and control circuits in one piece of equipment. Because of that mix, nec article 440 treats them as a special category with unique sizing, protection, and disconnect rules. Understanding these details prevents nuisance tripping, overheating conductors, and costly callbacks.

Why HVAC Equipment Has Special Code Rules

Air conditioning and refrigeration compressors do not behave like normal motors. They draw high starting current and often run continuously for long periods. Internal overload protection, nameplate ratings, and manufacturer instructions all play a bigger role than in standard branch circuits.

Nec article 440 recognizes these differences. Instead of using only general motor rules, the Code allows certain conductor and overcurrent sizing methods that match how HVAC equipment actually operates in the field.

Access our powerful online calculator now Conduit Fill Calculator (NEC Standard): Best Tool

Understanding Nameplate Ratings

The nameplate is the starting point for nearly every decision under nec article 440. Electricians often default to breaker sizing charts, but HVAC equipment must be sized from the data plate first.

Common nameplate terms include:

- Minimum Circuit Ampacity (MCA) – Used to size branch-circuit conductors

- Maximum Overcurrent Protection (MOCP) – The largest fuse or breaker allowed

- Rated-Load Current (RLC) – Used in some compressor calculations

- Locked Rotor Amps (LRA) – Indicates starting current, not conductor size

Ignoring MCA and MOCP is one of the most common violations related to nec article 440.

Learn all about Remote Monitoring Solutions for HVAC Automation USA

Conductor Sizing for HVAC Circuits

Unlike general-purpose circuits, conductor sizing for air conditioning units is based on the minimum circuit ampacity listed on the nameplate, not simply the breaker rating. Read in detail about nec 392.22

The rule is straightforward:

- Branch-circuit conductors must have an ampacity not less than MCA

This already includes adjustments for continuous load and motor starting characteristics. Upsizing conductors beyond MCA is allowed but not required unless derating factors apply.

| Nameplate Value | What It Means | What Electricians Must Do |

|---|---|---|

| MCA 28A | Minimum conductor ampacity | Use wire rated 28A or higher |

| MOCP 45A | Max breaker or fuse size | Do not exceed 45A OCPD |

| LRA 112A | Starting current | Not used for wire sizing |

This approach under nec article 440 avoids oversizing wire while still protecting the equipment.

Know more about NEC Grounding Table 250.122 Explained: Correct Equipment Grounding Conductor Size

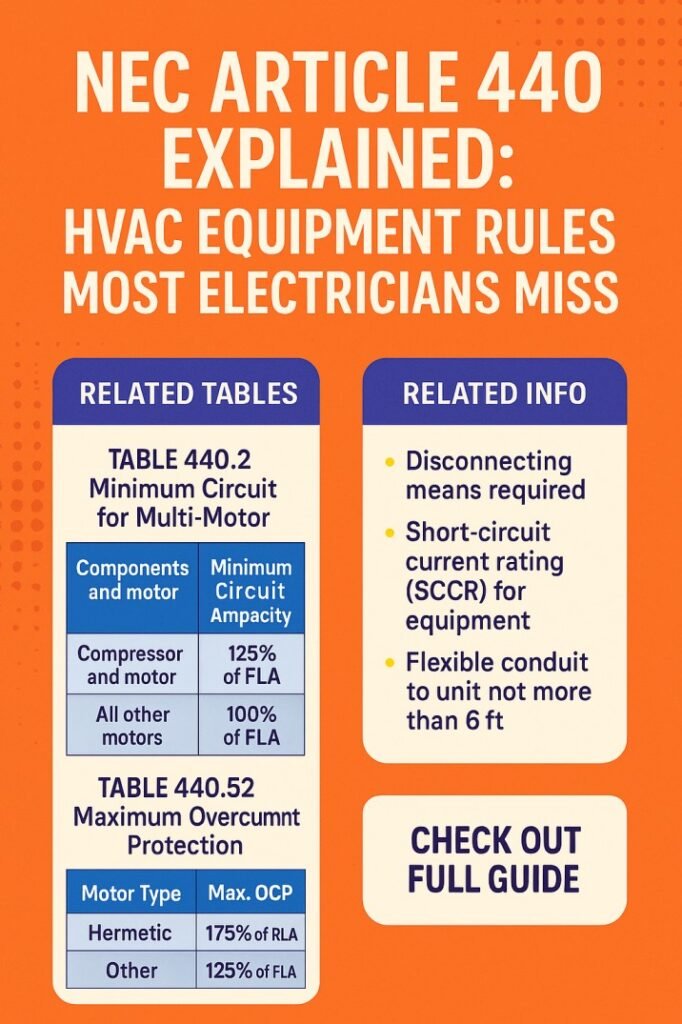

Overcurrent Protection Rules

Breaker sizing for HVAC equipment often looks wrong to someone used to standard motor rules. It is normal to see a 40A or 50A breaker feeding equipment with conductors rated for much less.

That is allowed because:

- The breaker protects against short circuits and ground faults

- The equipment has internal overload protection for running current

Nec article 440 permits overcurrent devices up to the MOCP value on the nameplate. If the exact size is not available, the next standard size up may be used within Code limits.

This is one of the most misunderstood areas, and inspectors frequently see breakers either undersized, causing nuisance trips, or oversized beyond the nameplate limit.

Know more about Benefits of VFD in HVAC Systems

Disconnecting Means Requirements

Every air conditioning and refrigeration unit must have a disconnect within sight from the equipment. This is a safety rule for service technicians.

Key points electricians miss:

- The disconnect must be readily accessible

- It does not always need to be fused if the breaker provides protection

- Cord-and-plug connections are allowed only for specific small equipment

Nec article 440 also allows the branch-circuit breaker to serve as the disconnect if it is within sight and lockable, but that is rare for outdoor condensers.

| Equipment Type | Disconnect Required | Common Mistake |

|---|---|---|

| Outdoor condenser | Yes, within sight | Mounted too far away |

| Rooftop unit | Yes | Not labeled correctly |

| Small window unit | Sometimes cord-and-plug | Hardwired without disconnect |

Explore all about NEC Article 344: Best Guide on Rigid Metal Conduit Installation & Code Compliance

Hermetic Refrigerant Motor-Compressors

Most HVAC compressors are hermetic, meaning the motor and compressor are sealed together. Nec article 440 has specific provisions just for these units.

Important differences include:

- Special overload protection rules

- Conductor sizing tied to compressor rating

- Unique treatment of motor branch-circuit protection

Because the overload device is built into the compressor, the external breaker does not have to protect against running overloads. This is why breaker sizes can seem large compared to conductor ampacity.

Multi-Motor and Combination Loads

Many HVAC systems include more than one motor. A condenser fan motor, blower motor, and compressor may all be in the same unit.

Instead of sizing each motor separately, nec article 440 allows a combined load calculation using the largest motor plus a percentage of the others. In factory-assembled equipment, this is usually already handled, and the nameplate MCA reflects the total.

Find out everything about NEC Article 400: Flexible Cords, Uses, Limits & Code Mistakes to Avoid

Electricians who try to recalculate everything from scratch often oversize conductors and overcurrent devices unnecessarily.

Grounding and Bonding

Proper grounding is essential for outdoor HVAC equipment exposed to weather and vibration.

Key grounding rules include:

- An equipment grounding conductor must run with the circuit conductors

- Metal raceways must be properly bonded

- Flexible metallic conduit must be listed for grounding or have a separate EGC

Loose fittings and corrosion are common failure points. These lead to high impedance fault paths and slow breaker operation.

Common Field Mistakes

Even experienced electricians make repeat errors with air conditioning circuits. Many of these problems come from treating HVAC equipment like standard motors.

Know everything about NEC Article 310 which include Ampacity Rules, Wire Sizing & Code Secrets Electricians Must Know

Frequent issues include:

- Using breaker size to select conductor size instead of MCA

- Exceeding the nameplate MOCP

- Forgetting the required disconnect within sight

- Ignoring manufacturer wiring diagrams

- Undersizing conductors after applying temperature derating

Each of these violations ties back to misunderstanding nec article 440 and how it differs from general wiring rules.

Service Receptacle Requirement

Outdoor HVAC equipment often requires a nearby service receptacle. While this rule appears in another article, it is closely associated with air conditioning installations.

The receptacle must be:

- Within 25 feet of the equipment

- On the same level

- GFCI protected

Electricians sometimes assume the disconnect location covers this requirement, but the receptacle is a separate rule.

Learn more about Demand Factor as Per NEC

Final Thoughts for Electricians

Air conditioning and refrigeration systems place heavy and unique demands on electrical systems. Nec article 440 provides a practical framework that matches real equipment behavior instead of textbook motor theory.

The key to passing inspections and avoiding callbacks is simple:

- Always start with the nameplate

- Size conductors from MCA

- Size overcurrent protection from MOCP

- Install a proper disconnect within sight

- Follow manufacturer instructions along with Code rules

When these steps are followed, installations run cooler, breakers stop tripping, and equipment lasts longer. Mastering nec article 440 is not just about passing inspection. It is about building safe, reliable HVAC power systems that perform year after year. Explore everything about NEC Article 220: A Comprehensive Guide

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#NECArticle440, #NECCode, #ElectricalCode, #HVACWiring, #MotorCircuits, #CompressorProtection, #ElectricalStandards, #CodeCompliance, #ElectricalEngineering, #IndustrialElectrical