PLC vs Microcontroller Programming Guide: Key Differences Engineers Must Know

Choosing between control platforms is a common challenge in modern automation. Many engineers struggle to decide which approach fits their project, budget, and performance needs. Understanding PLC vs microcontroller programming helps professionals make smarter technical decisions and avoid costly redesigns later.

Table of Contents

Industrial control has evolved rapidly in the last decade. Factories, smart machines, and embedded products now demand reliability, speed, and flexibility at the same time. Both PLCs and microcontrollers can deliver automation, but they serve different purposes. Knowing where each one excels is the key to efficient system design.

What Is a PLC?

A Programmable Logic Controller, or PLC, is an industrial computer built for automation tasks. It controls machines, production lines, motors, and process systems in harsh environments.

Know more about PLC vs DCS: Main Differences for Industrial Automation

PLCs are designed to survive vibration, electrical noise, temperature extremes, and dust. They are widely used in manufacturing, water treatment, oil and gas, and power plants.

Key characteristics of PLCs include:

- Modular input and output systems

- Rugged industrial hardware

- Standardized programming languages like Ladder Logic

- Built-in diagnostics and fault handling

- Easy integration with industrial networks

When discussing PLC vs microcontroller programming, PLCs stand out for reliability and ease of maintenance in large systems.

Know more about Remote Monitoring with PLC and IoT Integration

What Is a Microcontroller?

A microcontroller is a compact integrated circuit that contains a processor, memory, and peripherals on a single chip. It is commonly used in embedded systems such as consumer electronics, IoT devices, automotive modules, and portable equipment.

Unlike PLCs, microcontrollers are not limited to industrial control. They can be programmed for almost any digital task, from reading sensors to running displays.

Typical microcontroller features include:

- Low cost and small size

- Flexible programming in C, C++, or assembly

- Direct hardware control

- Low power consumption

- Custom hardware design options

In the context of PLC vs microcontroller programming, microcontrollers offer deep customization and performance control but require more design effort. Explore everything about Automation Engineer Certification Cost in 2026 – Fees, Duration & Best Value Programs

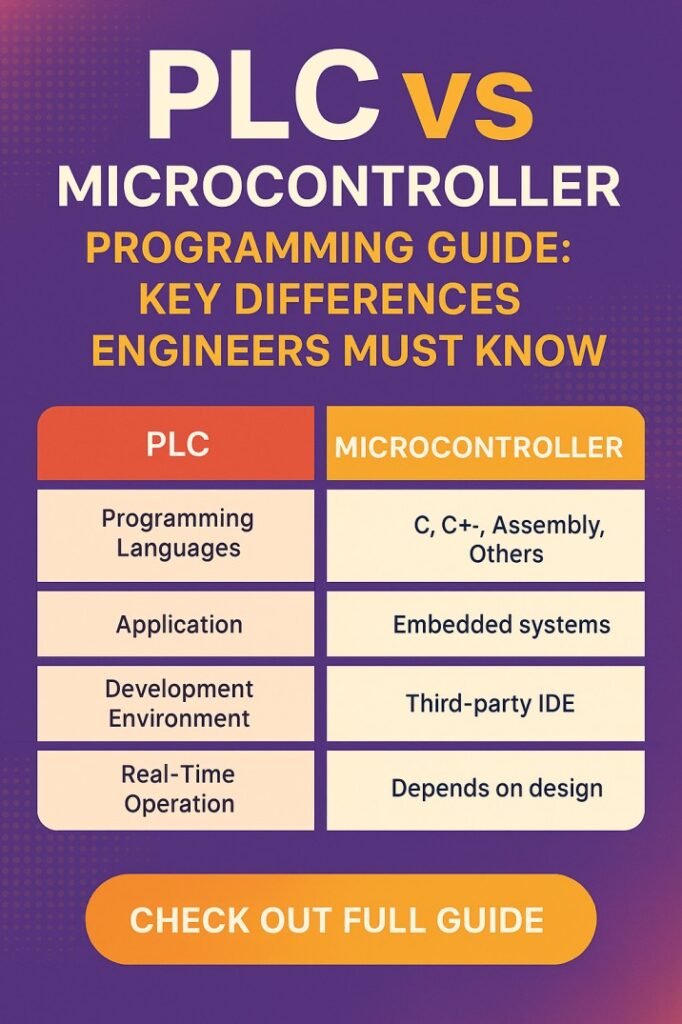

Core Differences at a Glance

Understanding the major technical contrasts makes selection easier. The table below summarizes the most important aspects engineers compare.

| Feature | PLC | Microcontroller |

|---|---|---|

| Primary Use | Industrial automation | Embedded systems |

| Programming Style | Ladder, Function Block, Structured Text | C, C++, Assembly |

| Hardware Design | Ready-made industrial modules | Custom circuit design |

| Environmental Rating | High (dust, vibration, EMI) | Depends on design |

| Cost per Unit | Higher | Very low in volume |

| Real-Time Control | Deterministic scan cycle | Interrupt and timer based |

| Maintenance | Easy module replacement | Board-level troubleshooting |

| Startup Time | Fast and predictable | Depends on firmware |

This comparison highlights why PLC vs microcontroller programming is not just a software choice, but a system-level decision.

Know more about Top SCADA Software Platforms for Energy Sector

Programming Language Differences

Programming style is one of the biggest contrasts.

PLC Programming

PLCs use IEC 61131-3 standard languages. The most common is Ladder Logic, which looks like electrical relay diagrams. This makes it easy for technicians and electricians to understand.

Other PLC languages include:

- Function Block Diagram (FBD)

- Structured Text (similar to Pascal)

- Sequential Function Chart (SFC)

These languages are designed for clarity, safety, and troubleshooting. In PLC vs microcontroller programming, PLC code is usually easier for maintenance teams to modify. Learn everything about SCADA vs DCS Comparison

Microcontroller Programming

Microcontrollers are programmed using traditional software languages like C or C++. Engineers must manage memory, interrupts, and hardware registers directly.

This provides:

- Greater control over performance

- Faster execution for complex algorithms

- Flexibility for custom communication protocols

However, debugging can be harder without industrial diagnostic tools. This makes PLC vs microcontroller programming a tradeoff between simplicity and control.

Know more about HMI vs SCADA: Which System Should You Choose?

Hardware and System Design

PLCs are modular and ready to deploy. Engineers select input modules, output modules, communication cards, and power supplies, then mount them on a DIN rail. Wiring is straightforward and standardized.

Microcontrollers require a custom PCB design. Engineers must design:

- Power regulation circuits

- Signal conditioning for sensors

- Protection against voltage spikes

- Communication interfaces

Because of this, PLC vs microcontroller programming often depends on whether the project allows custom hardware development.

Reliability and Environment

PLCs are built for factories where electrical noise and temperature swings are common. They include isolation, surge protection, and watchdog timers.

Microcontrollers can also be reliable, but only if the circuit is designed carefully. Extra components are needed for protection.

In harsh environments, PLC vs microcontroller programming usually favors PLCs due to proven industrial durability.

Real-Time Performance

PLCs operate using a scan cycle. They read inputs, execute logic, and update outputs in a fixed loop. This predictable timing is ideal for machine control.

Microcontrollers rely on interrupts and timers. They can respond very quickly, often faster than PLCs, but timing depends on firmware design.

Know more about Industrial IoT Sensors in Automation: Cost and Integration

For high-speed motion control or signal processing, PLC vs microcontroller programming may lean toward microcontrollers. For predictable industrial sequencing, PLCs are often preferred.

Cost Considerations

Cost plays a big role in technology selection.

| Cost Factor | PLC | Microcontroller |

|---|---|---|

| Initial Hardware | High | Low |

| Engineering Time | Lower | Higher |

| Maintenance Cost | Lower | Medium to High |

| Production Volume | Best for low to medium | Best for high volume |

In small production runs, PLCs can actually be cheaper due to reduced design time. In mass-produced devices, microcontrollers win. This financial balance is central to PLC vs microcontroller programming decisions.

Safety and Standards

PLCs often come with safety certifications and support for safety-rated I/O modules. They integrate easily with emergency stop circuits and industrial safety systems.

Microcontrollers can be used in safety systems, but certification is more complex and requires careful design and documentation.

Know more about OPC UA vs MQTT: Protocol Comparison for Industrial Control

When compliance with industrial standards is critical, PLC vs microcontroller programming usually favors PLC platforms.

Communication and Networking

Modern PLCs support industrial protocols such as:

- Modbus

- Profinet

- EtherNet/IP

- CANopen

These are built into modules and require minimal configuration.

Microcontrollers can also support these protocols, but engineers must implement stacks or use external chips. This increases development time.

For large automation networks, PLC vs microcontroller programming often points toward PLCs for easier integration.

When to Choose a PLC

A PLC is usually the best choice when:

- The system operates in an industrial environment

- Downtime must be minimized

- Maintenance staff need easy troubleshooting

- The project uses standard industrial sensors and actuators

- Safety compliance is required

These situations highlight where PLC vs microcontroller programming clearly supports PLC-based control.

Know more about Modbus Communication Protocol: Master-Slave Explained

When to Choose a Microcontroller

A microcontroller is often better when:

- The product will be manufactured in high volumes

- Space is limited

- Low power consumption is required

- Advanced algorithms or signal processing are needed

- The system is part of a consumer or portable device

Here, PLC vs microcontroller programming leans toward embedded solutions.

Skill Set Requirements

PLCs are easier for technicians and automation engineers to maintain. The logic is visual and tools are user-friendly.

Microcontroller development requires embedded programming knowledge, electronics design, and debugging skills using oscilloscopes and logic analyzers.

Team expertise strongly affects PLC vs microcontroller programming choices.

Know more about PLC Programming Salary 2026 – Experience-Wise Pay, Country Comparison & Skills That Boost Income

Scalability and Expansion

PLCs are designed for expansion. Adding more I/O modules or communication cards is simple.

Microcontroller systems need redesign if major expansion is required. This increases cost and complexity.

For growing industrial systems, PLC vs microcontroller programming often favors PLC architecture.

Final Thoughts

Both technologies are powerful, but they serve different engineering goals. PLCs provide reliability, standardization, and easier maintenance in industrial automation. Microcontrollers offer flexibility, compact size, and cost efficiency for embedded products.

Know more about SCADA HMI Software Cost in 2026 – Pricing, Licenses & Best Value Options

The decision should be based on environment, production volume, performance needs, and team expertise. By understanding PLC vs microcontroller programming, engineers can design systems that are efficient, maintainable, and future-ready.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#PLCProgramming, #MicrocontrollerProgramming, #IndustrialAutomation, #EmbeddedSystems, #ControlSystems, #AutomationEngineering, #PLCvsMicrocontroller, #ElectronicsEngineering, #IndustrialControl, #SmartManufacturing